Method for recycling the carbon-chuck for manufacture of polycrystalline silicon

A polysilicon and graphite technology, which is applied in the field of reuse of graphite chucks for polysilicon manufacturing, can solve problems such as being unsuitable for semiconductors or solar cells, and achieve the effects of effective reuse and improved economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

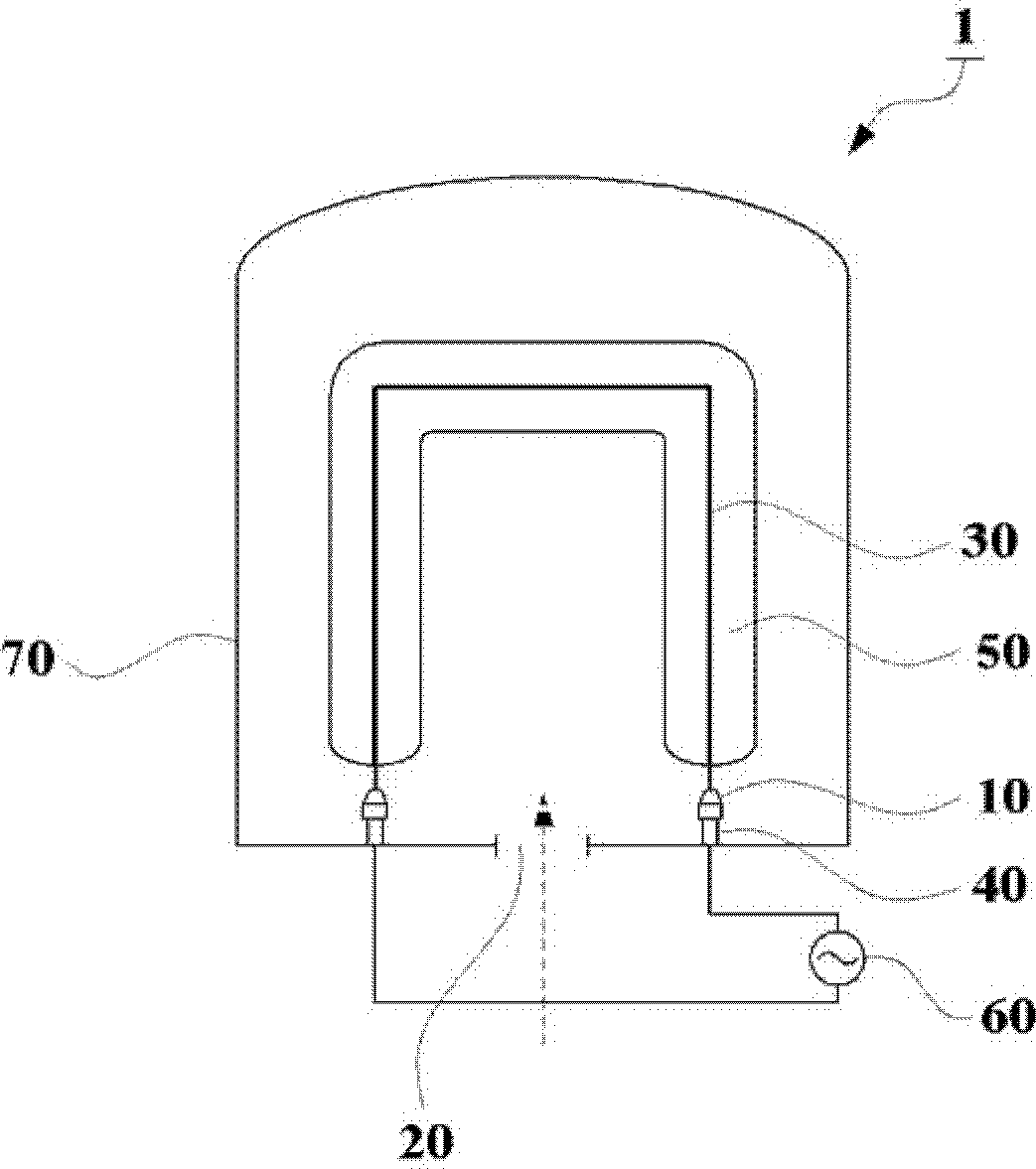

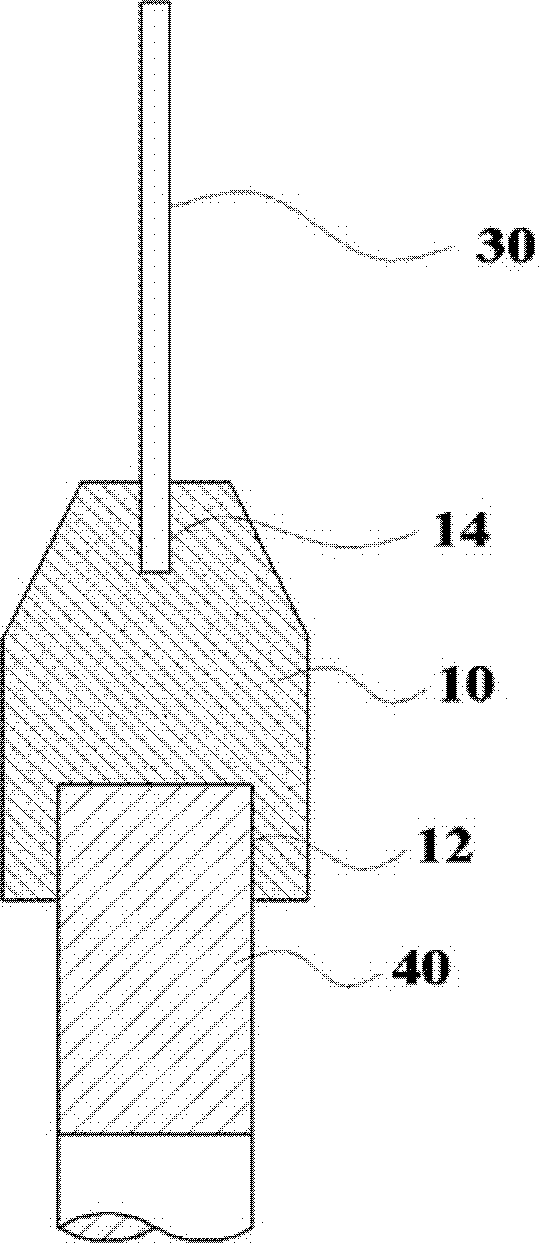

[0028] Hereinafter, specific embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0029] The method for reusing the graphite chuck for polysilicon manufacturing according to the present embodiment includes the following steps.

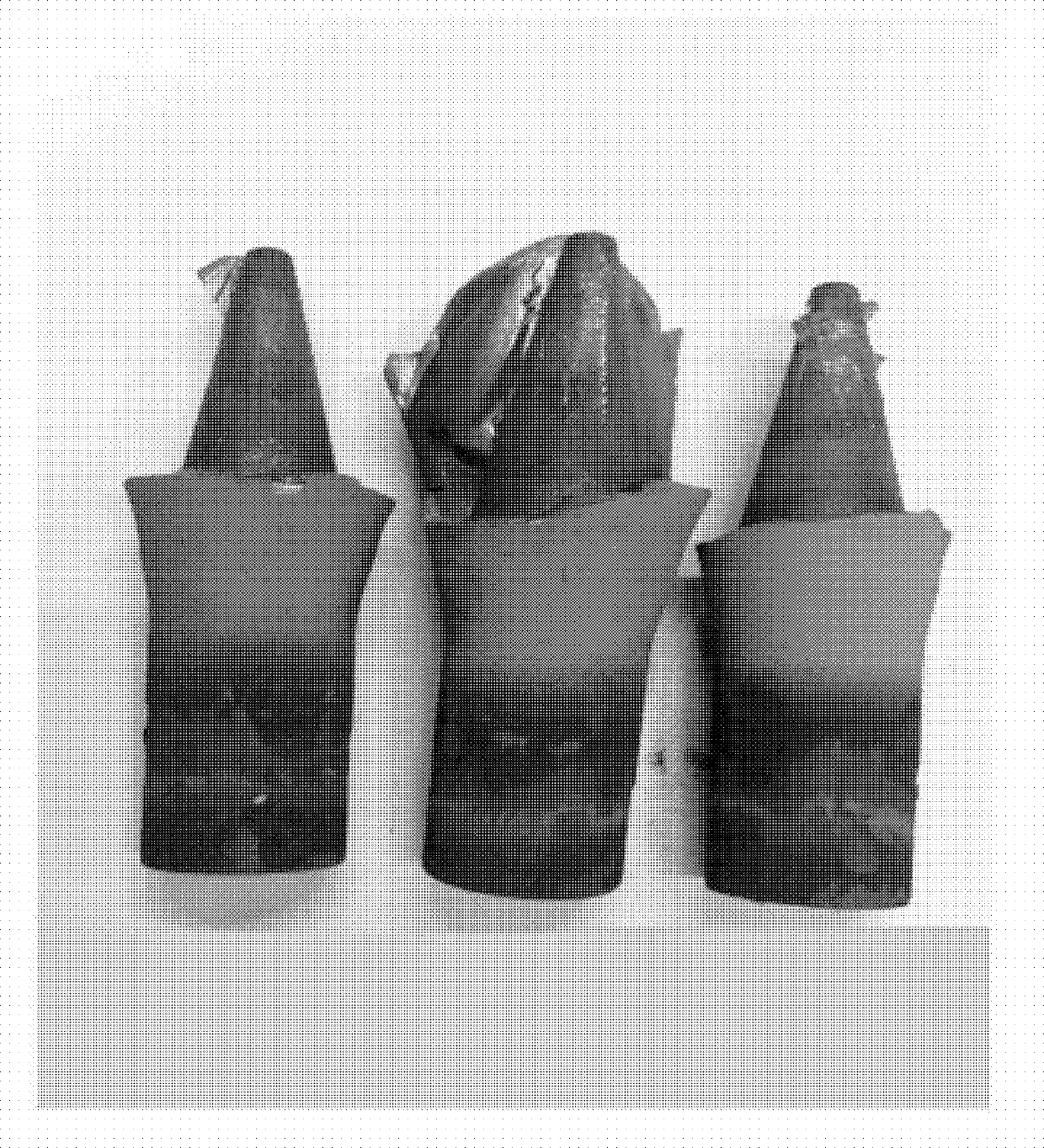

[0030] First, a step ( S100 ) of separating the graphite chuck-polysilicon end from the silicon ingot is performed. In this embodiment, the graphite chuck-polysilicon end (Carbon chuck-PolySilicon End) refers to the graphite chuck used in the polysilicon manufacturing process in the above-mentioned Siemens reactor, which can be obtained from image 3 It was confirmed that it was in a state where polysilicon was attached on its outer surface.

[0031] The specific technique for separating the above-mentioned graphite chuck-polysilicon end from the grown silicon ingot is generally substantially the same as the process used in the polysilicon manufacturing process, and thus a detailed description...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap