Pressure-sensitive heat-resistant sealed microcapsule

A microcapsule and sensitive technology, applied in the preparation of microcapsules, adhesives, microspheres, etc., can solve the problems of low mechanical strength, complex production equipment, poor sealing of wall materials, etc., achieve high mechanical strength, excellent sealing, external pressure sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

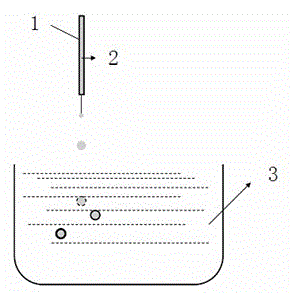

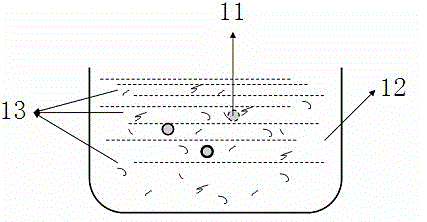

[0023] A pressure-sensitive heat-resistant sealed microcapsule, the microcapsule includes a core material and a wall material coated on the outside of the core material, the core material is ethylenediamine, and the wall material is epoxy resin E-51 reacted with ethylenediamine The resulting cured resin has a mass ratio of core material to wall material of 1:2. The preparation method is as follows:

[0024] 50g of epoxy resin E-51 and 2.5g of ethylenediamine, pre-polymerized at 50°C for 10min, then dissolved in 500ml of carbon tetrachloride, then 25g of ethylenediamine was added dropwise into the solution with a needle and kept at 50°C, The microcapsule wall is solidified and formed, filtered, washed and dried to obtain microcapsules.

Embodiment 2

[0026] Another pressure-sensitive heat-resistant sealed microcapsule, the microcapsule includes a core material and a wall material coated on the outside of the core material, the core material is tetraethylenepentamine, and the wall material is epoxy resin E-44, styrene oxide It is a cured resin produced by the reaction of SO and triethylenetetramine. The preparation method is as follows:

[0027] 40g of epoxy resin E-44, 10g of styrene oxide SO and 3.0g of triethylenetetramine, pre-polymerized at 50°C for 8min, then dissolved in 500ml of DBP, and then 22.5g of tetraethylenepentamine was added dropwise to the solution with a needle Keep at 50°C in the middle, filter, wash and dry to obtain microcapsules after the microcapsule walls solidify and form.

Embodiment 3

[0029]50g of epoxy resin E-51 and 4.5g of CAPCURE WR-6, pre-polymerized at 20°C for 12min, then dissolved in 500ml of xylene, then dripped CAPCURE WR-6, 32g into the solution with a needle and kept at 20°C, until The microcapsule wall is solidified and formed, filtered, washed and dried to obtain microcapsules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com