Air stopping and material guiding device for pyrolysis channel

A material guide device and channel technology, applied in the field of environmental engineering, can solve problems such as backflow of difficult spiral pipes, and achieve the effect of preventing backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

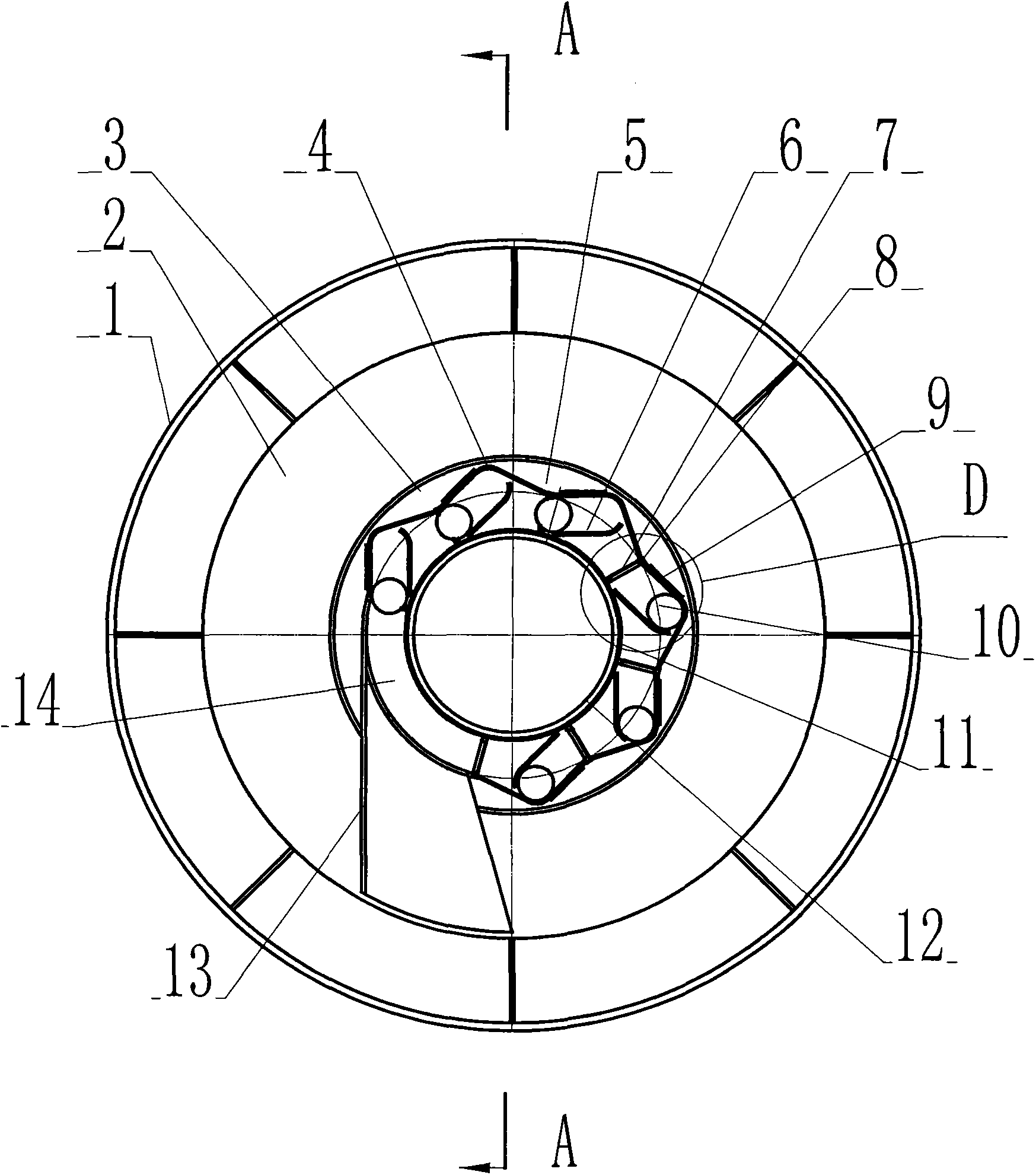

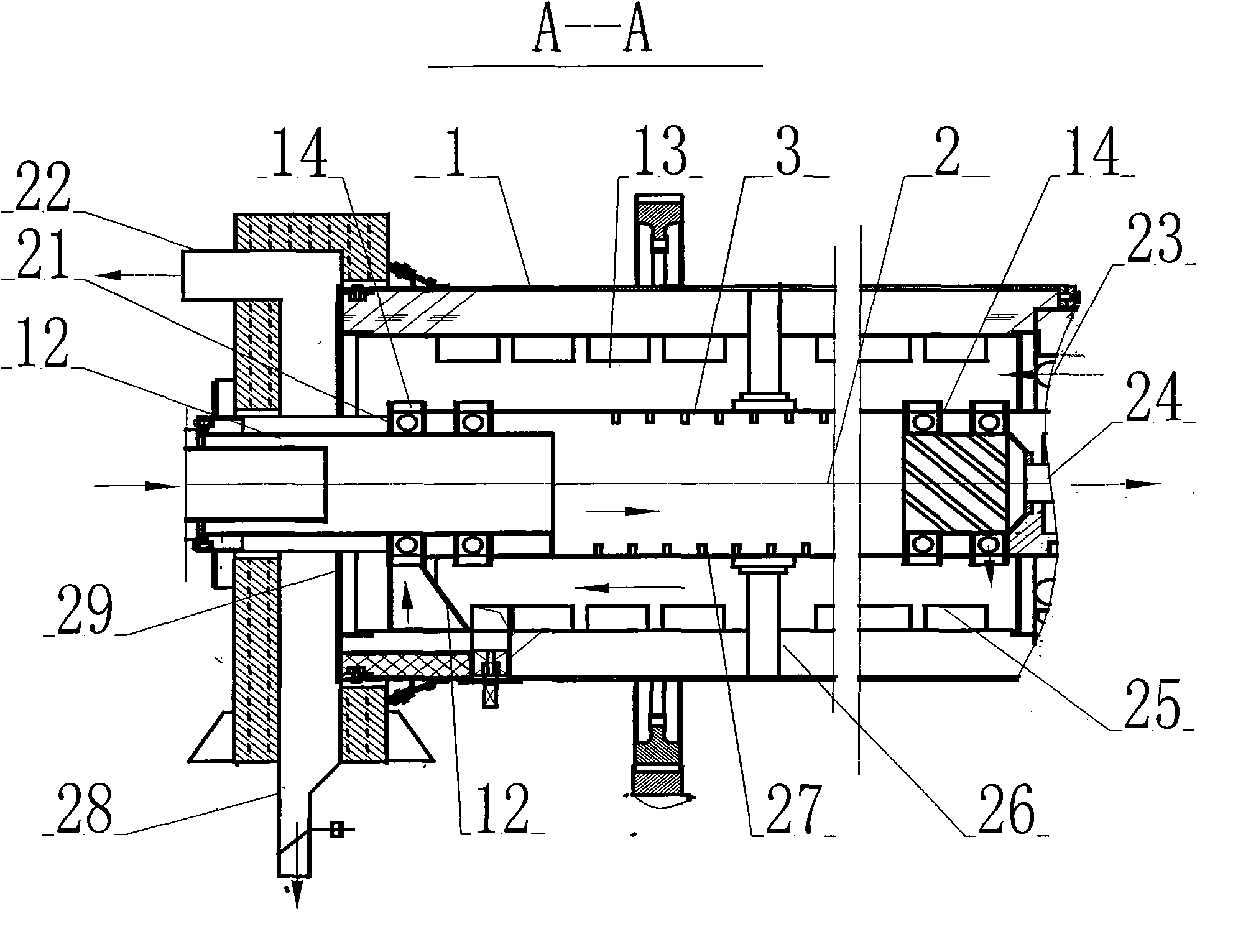

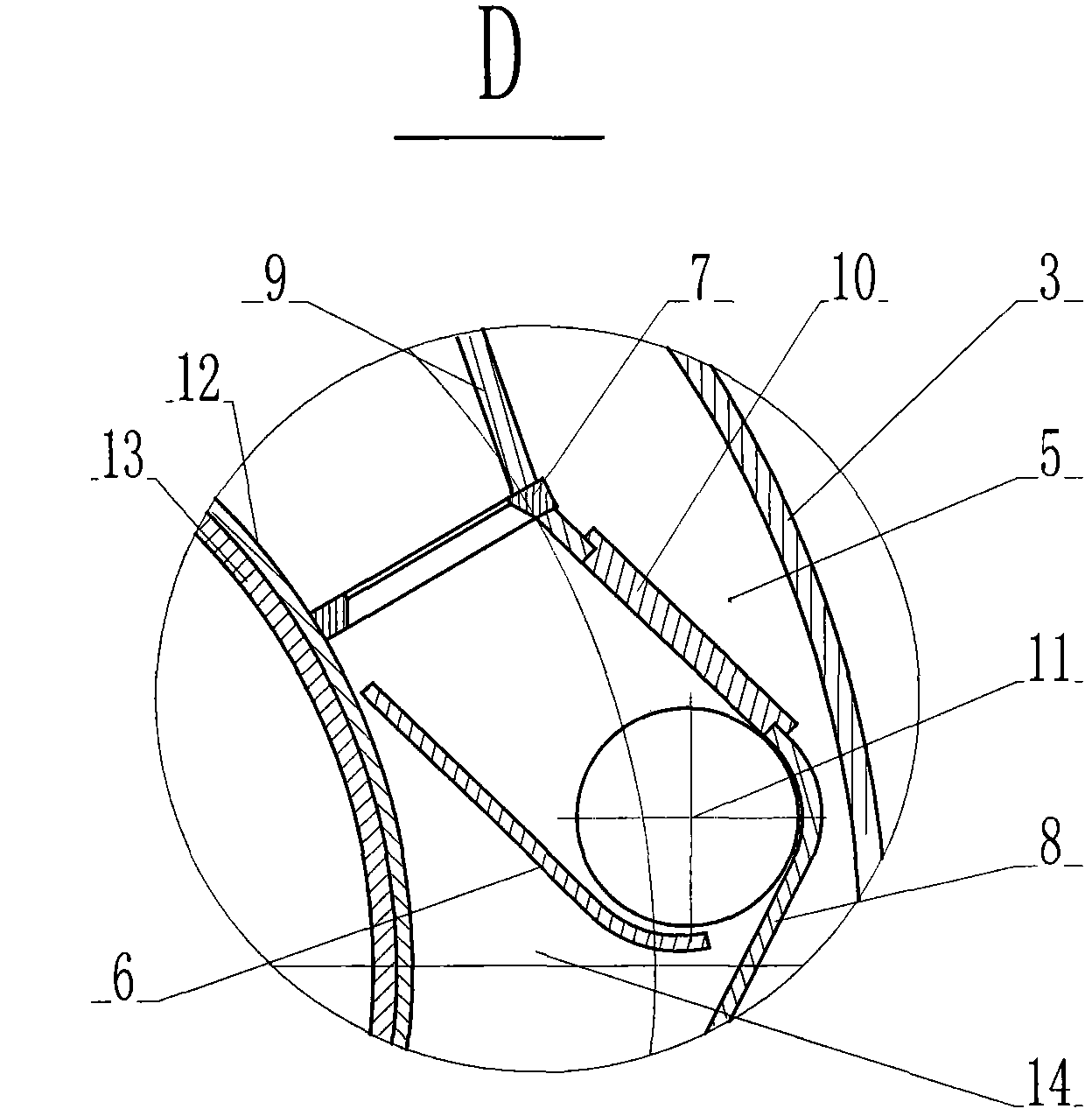

[0022] The gas-blocking material guide device of the pyrolysis channel, which includes: a spiral ring pipe 14, the inner ring surface 11 of which is a cylindrical surface, which is sleeved outside the feed conduit 12, the outer ring surface 8 is a polygonal cylindrical surface, and the two sides are spiral The surface 21 seals the inner ring surface and the outer inner ring, so that the spiral ring pipe forms a channel with variable cross-section. The outer cylinder 1 and the inner cylinder 3 of the cylinder pyrolysis rotary kiln are connected, and the axial lift of the inlet and outlet is greater than one screw moment;

[0023] A group of ball valve ports 7 are respectively radially separated from the smallest radial cross-section of the helical annular tube variable cross-section, and the area of the ball valve ports should meet the requirements of the flow rate of the heat carrier;

[0024] A group of steel balls 10 are arranged one by one on the rear side of the ball val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com