High dam spillway foundation drainage system and excavation method

A technology for underground spaces and buildings, which is applied in excavation, water conservancy engineering, and infrastructure engineering, etc., can solve the problems of incompatibility with the deformation characteristics of weak rock formations, large excavation and support excavation areas, and high excavation and support costs. Effect of reducing water load, reducing engineering quantity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

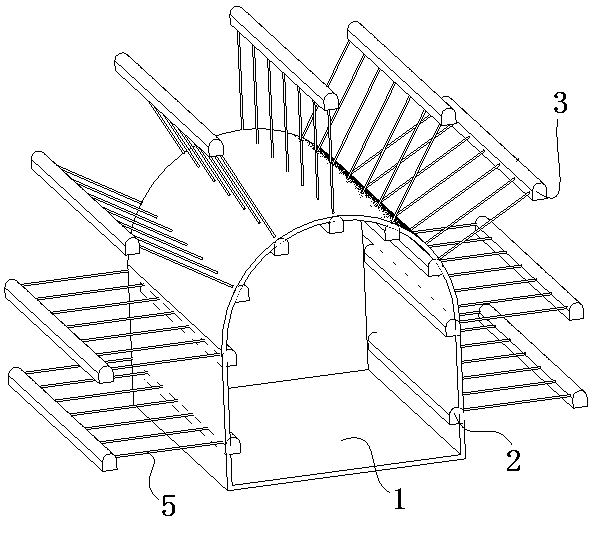

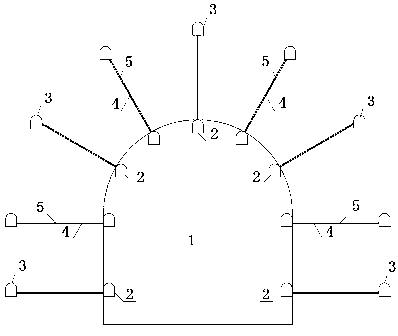

[0025] An underground space building with large span and high side walls in weak rock formation, such as figure 1 and 2 As shown, it includes an underground space building body 1, a pre-anchor hole 2 at the sideline, a pre-anchor hole 3 outside the boundary line, a penetrating pre-anchor hole 4, and a penetrating prestressed anchor rod or cable 5.

[0026] The specific steps of the excavation support method for the large-span high-side wall underground space building are as follows:

[0027] Firstly, corresponding pre-anchor holes 2, 3 that can accommodate and implement drilling operations are respectively excavated at the structural sideline of the building body 1 in the designed underground space and a certain range nearby;

[0028] Secondly, drill and dig the cross-piercing anchor hole 4 between the corresponding pre-anchor hole 2 and the pre-anchor hole 3; Implement pre-anchor before excavation of long-span underground structures;

[0029] Finally, using the drainage ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com