An Online Monitoring and Diagnosis System for Full Hydraulic Drilling Rig

A diagnostic system and full hydraulic technology, which is applied in the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc., can solve the problems of difficult fault diagnosis and rig movement of drilling rigs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

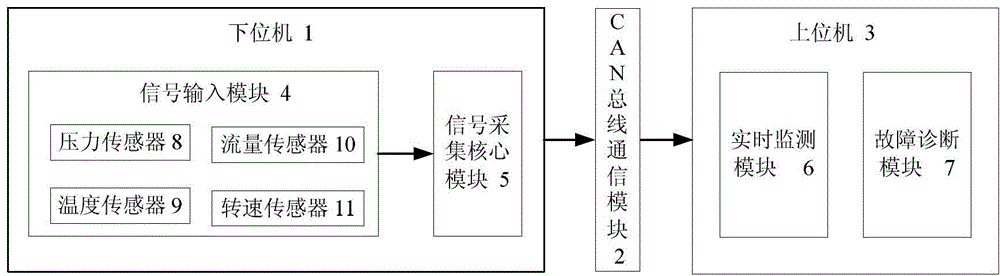

[0016] Such as figure 1 As shown, an online monitoring and diagnosis system for a full hydraulic drilling rig of the present invention mainly includes a lower computer 1 for data acquisition and conditioning, a CAN bus communication module 2 for data transmission, and a monitoring and fault identification for drilling rig parameters. Upper computer 3.

[0017] The signal input module 4 of the lower computer 1 uses the pressure sensor 8, the temperature sensor 9, the flow sensor 10 and the speed sensor 11 to collect the operation status information of the full hydraulic drilling rig in an all-round way, and input it to the signal acquisition core module 5 for conditioning and amplification .

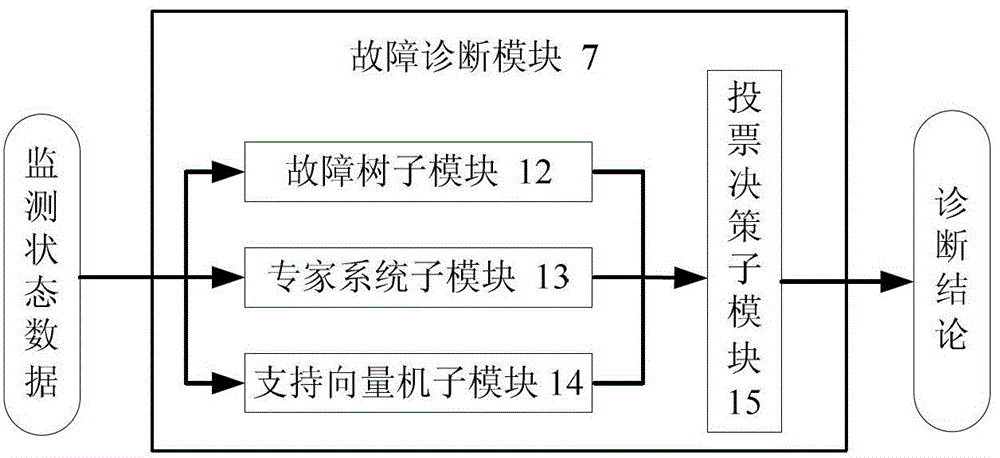

[0018] Through the CAN bus communication module 2, the drilling rig status data collected by the lower computer is transmitted to the upper computer 3, and the real-time monitor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com