Fault detection device

A technology of fault detection and detection unit, which is applied in the direction of pump testing, liquid displacement machinery, machine/engine, etc., can solve the problems of lack of rapid detection of compressor faults, reduce fault repair time, reduce production and maintenance costs, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

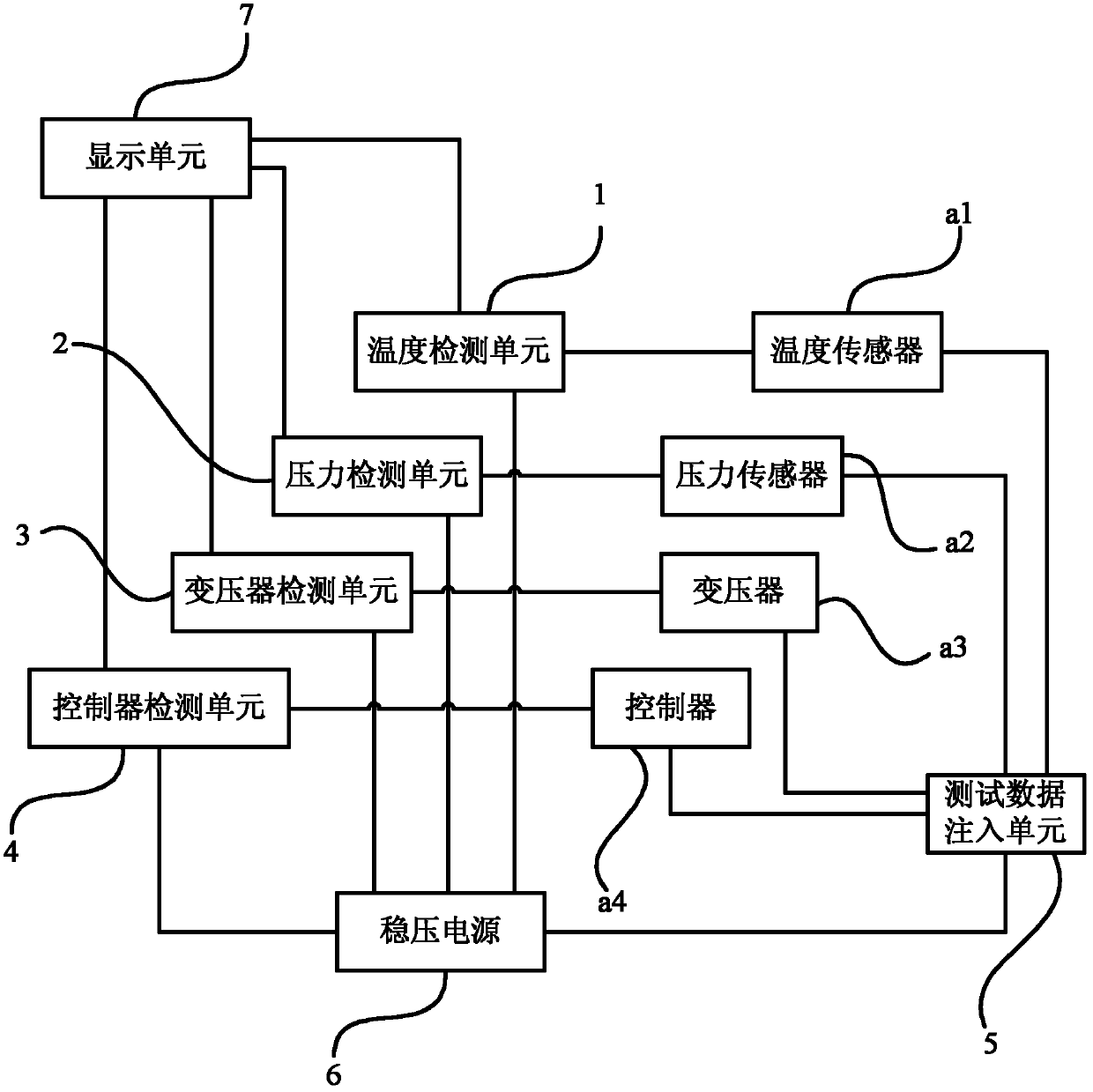

[0019] The fault detection device of this embodiment includes a temperature detection unit 1, a pressure detection unit 2, a transformer detection unit 3, a controller detection unit 4, a test data injection unit 5, a display unit 6 and a stabilized power supply 7.

[0020] The test data injection unit 5 is used to input a temperature test data D1, a pressure test data D2, a pressure sensor a2, a transformer a3 and a controller a4 in a screw compressor A respectively. A voltage test data D3 and a logic test data D4, that is, the test data injection unit 5 of this embodiment inputs test data to each component of the screw compressor A, so that subsequent detection components output data by detecting each component It is the same as the expected output data to judge whether each component is operating normally.

[0021] In this embodiment, the temperature detection unit 1 is used to detect whether the output data Dout_a1 obtained from the temperature sensor a1 of the screw comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com