Three-cavity spring braking gas chamber

A technology of spring brake air chamber and spring cavity, which is applied in the direction of brake actuator, gear transmission mechanism, mechanical equipment, etc., can solve the problems of inconvenient operation of the brake air chamber, inability to apply the parking brake normally, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

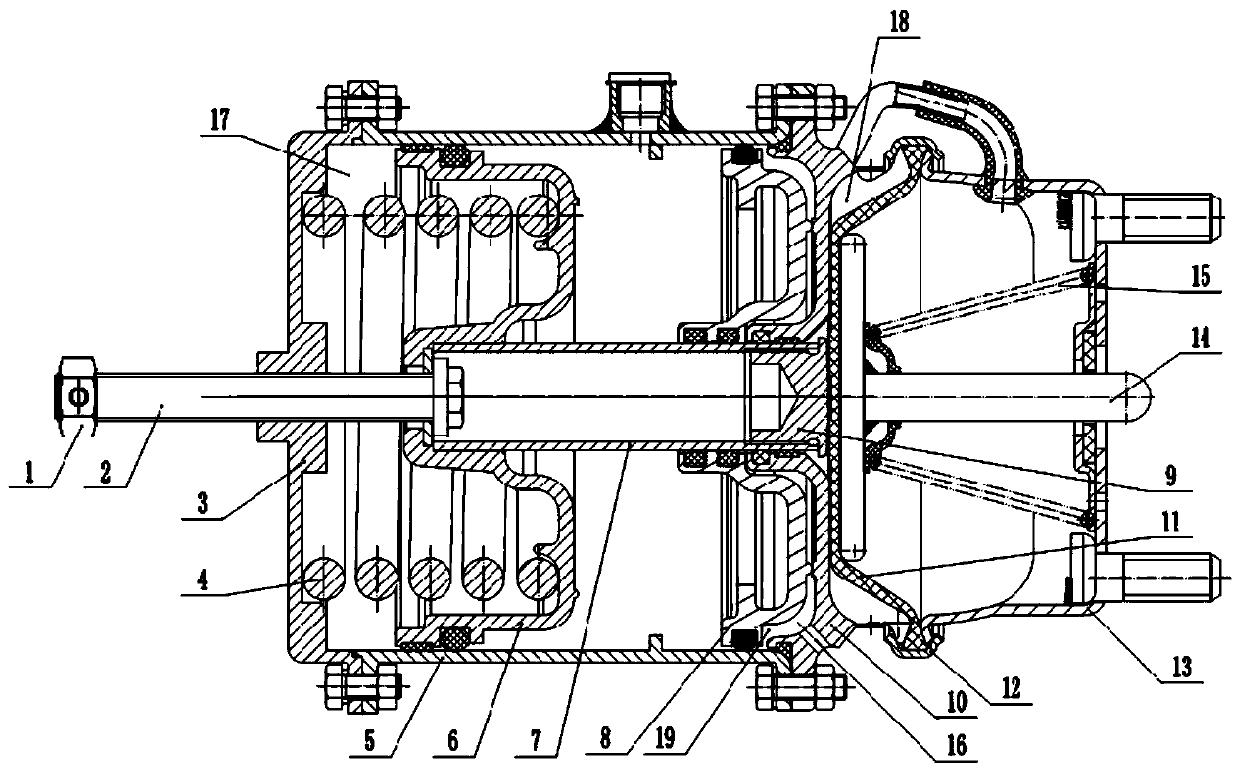

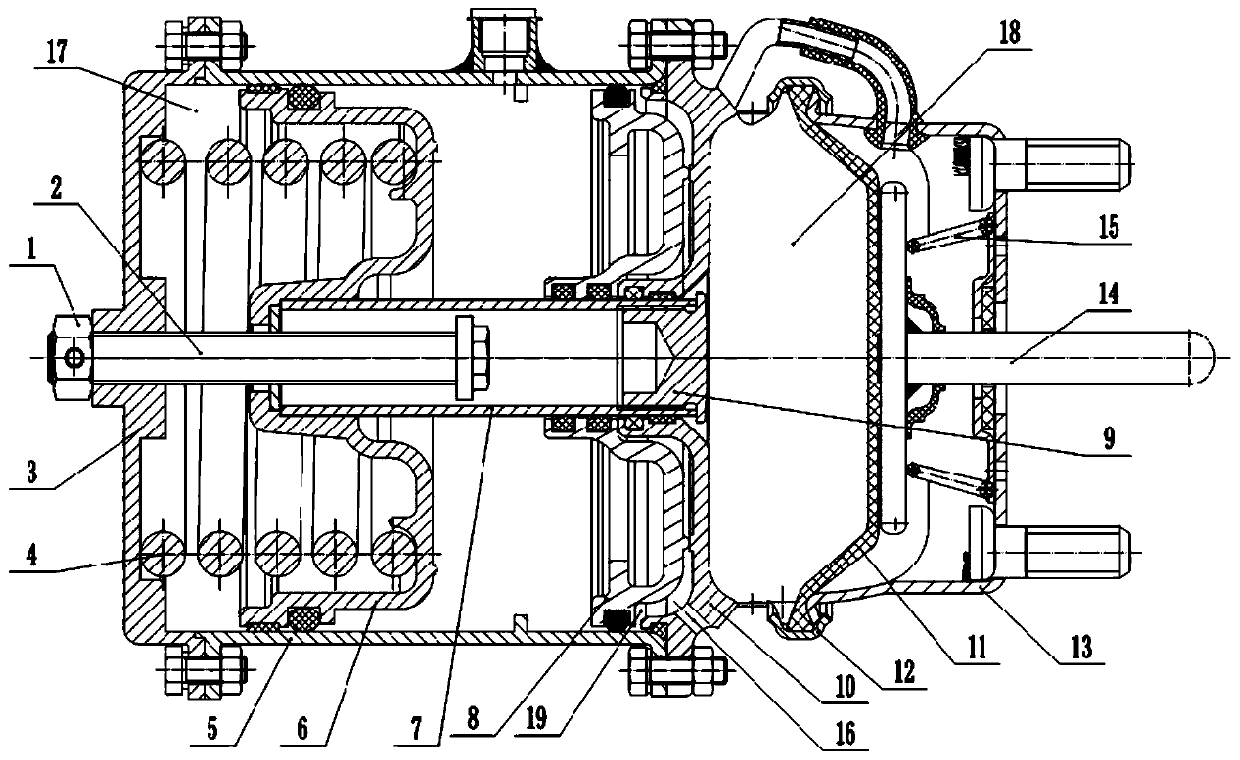

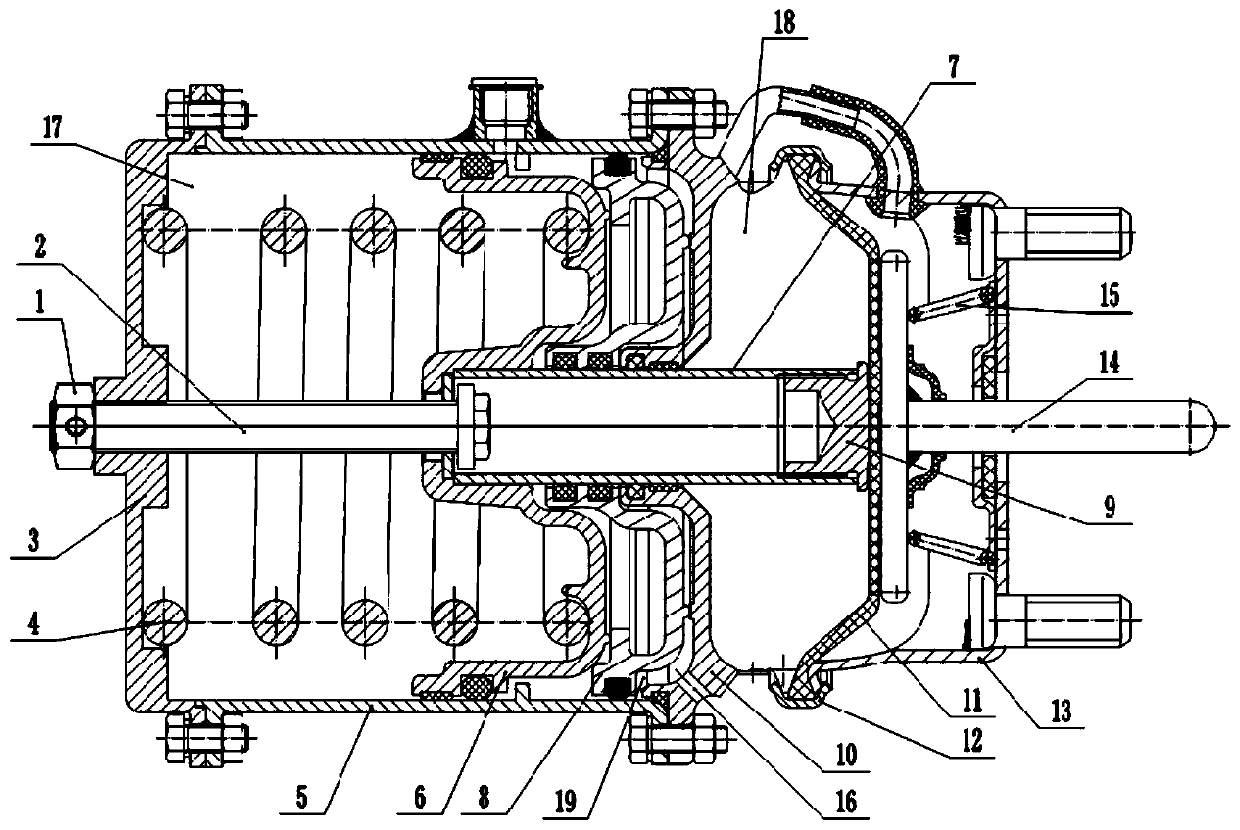

[0024] A three-chamber spring brake chamber, as attached figure 1 As shown, it mainly consists of cylinder body 5, cover plate 3, connecting seat 10, fixed seat 13, screw rod 2, hollow cylinder 7, parking piston 6, parking brake spring 4, relief piston 8, diaphragm 11, lock ring 12, Push rod 14, back-moving spring 15 constitute.

[0025] The left side of the cylinder body 5 is connected with the cover plate 3 by bolts, and the right side of the cylinder body 5 is connected with the connecting seat 10 by bolts. The left part of the cylinder body 5 is slidably connected with a parking piston 6, and a spring chamber 17 is formed between the cover plate 3 and the parking piston 6, and a parking brake spring 4 is installed in the spring chamber 17.

[0026] The right part of the cylinder block 5 is slidably connected with a relief piston 8, and a parking brake chamber is formed between the relief piston 8 and the parking piston 6, and the parking brake chamber is connected with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com