Pollution and abrasion test system for electro-hydraulic servo valve

A technology of electro-hydraulic servo valve and test system, which is applied in the field of variable and controllable oil pollution of electro-hydraulic servo valve and hydraulic test system, which can solve the complicated and multi-dimensional problems of the size and hardness of electro-hydraulic servo valve pollutants. Changes, difficult guarantees, deviations, etc., to achieve high reliability, easy operation, and avoid test errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in detail below in conjunction with accompanying drawing:

[0037] The technical scheme provided by the invention is:

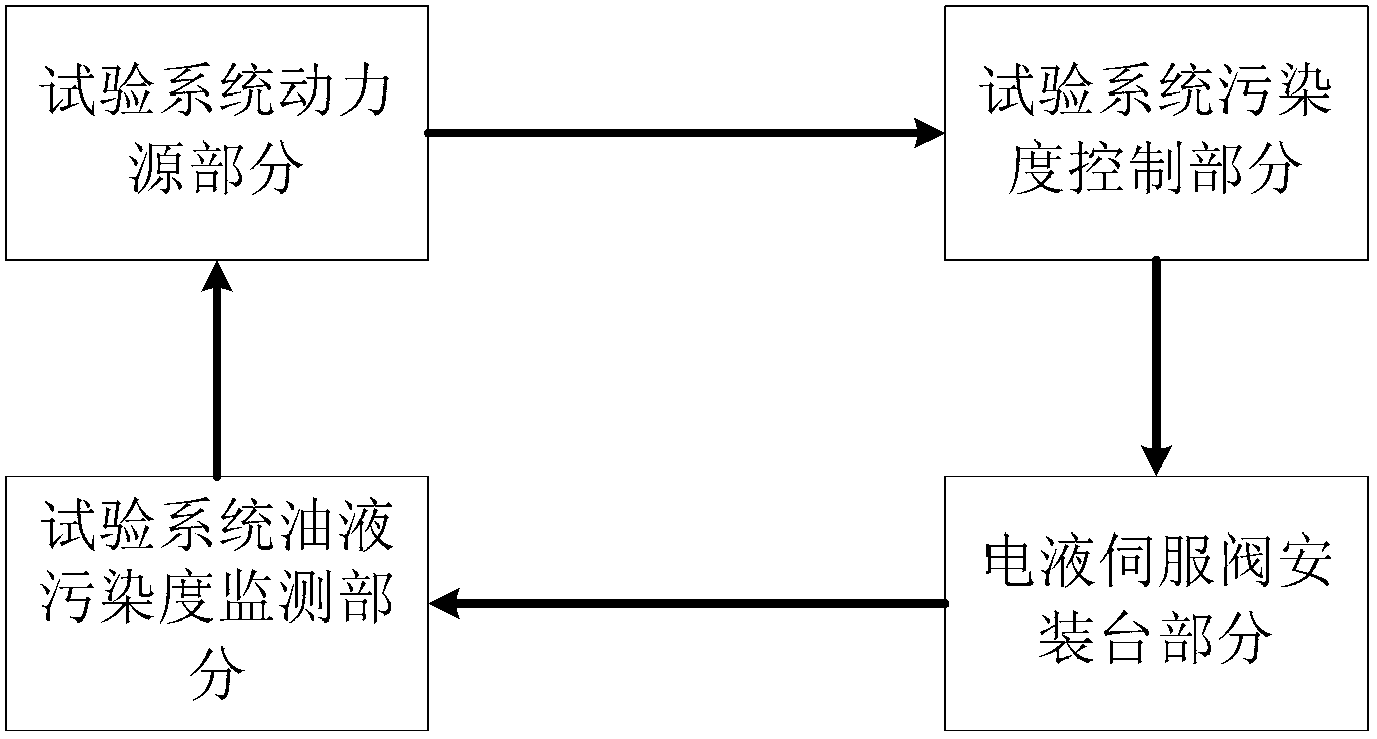

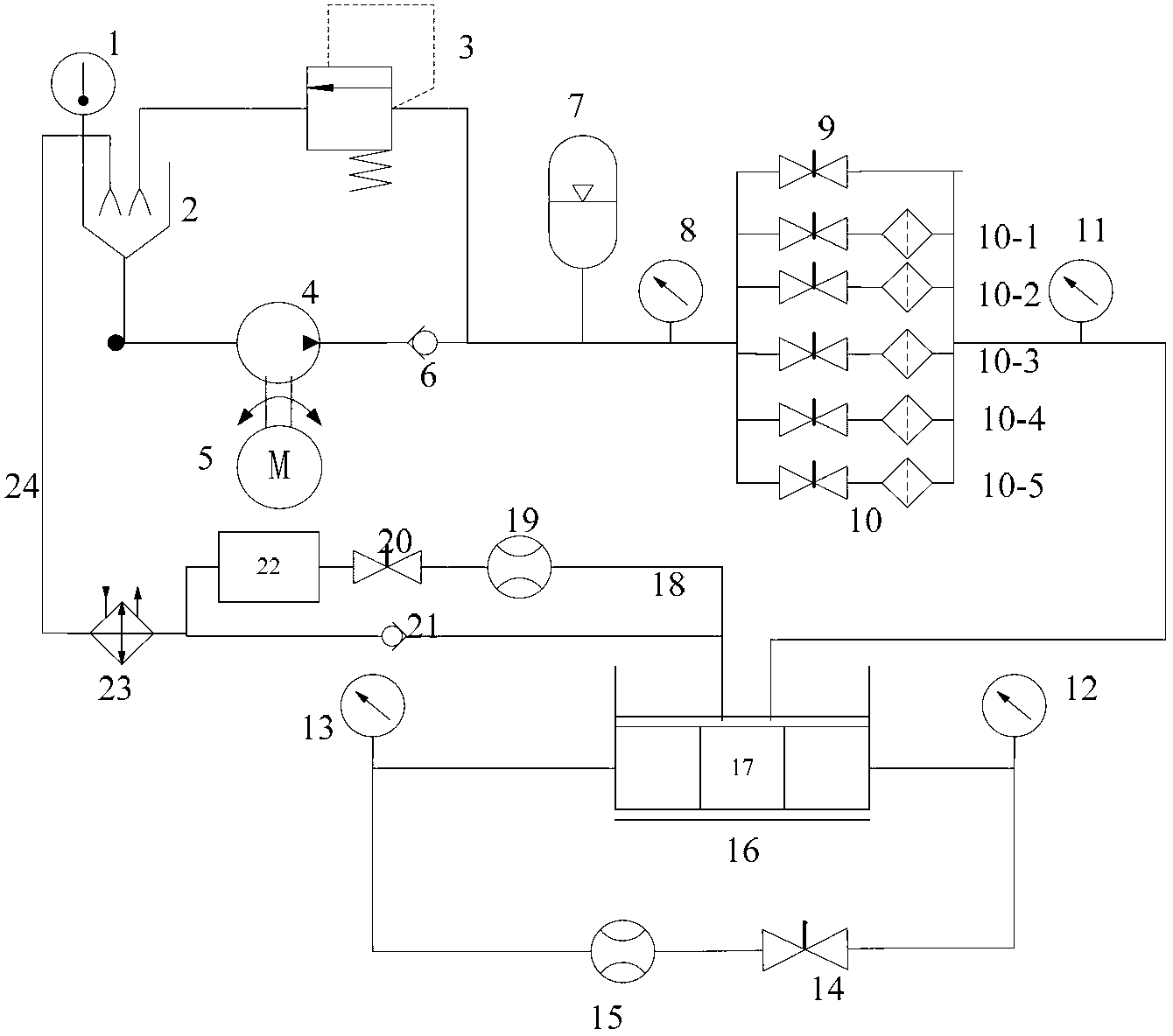

[0038] See figure 1 , 2 As shown, the present invention is an electro-hydraulic servo valve pollution wear test system, the specific composition of the system includes:

[0039] The first part is the power source of the test system, which provides the source power for the whole test system; the second part is the oil pollution degree control part, which is directly connected behind the power source of the system, and consists of a pipeline with only one switch and five routing switches and The parallel connection of pipelines composed of oil filters in series is the control part of the working oil pollution degree in the test; the third part is the installation platform part of the electro-hydraulic servo valve, which is connected between the pollution level control part and the fourth part system oil pollution degr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com