Scale-free direct-current gas boiler for heat pipe heat setting pool provided with double coils and furnace flue

A dual-coil, gas-fired boiler technology, applied in heat storage heaters, preheating, air heaters, etc., can solve the problems of reduced service life, low thermal efficiency and test efficiency, and energy-saving losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

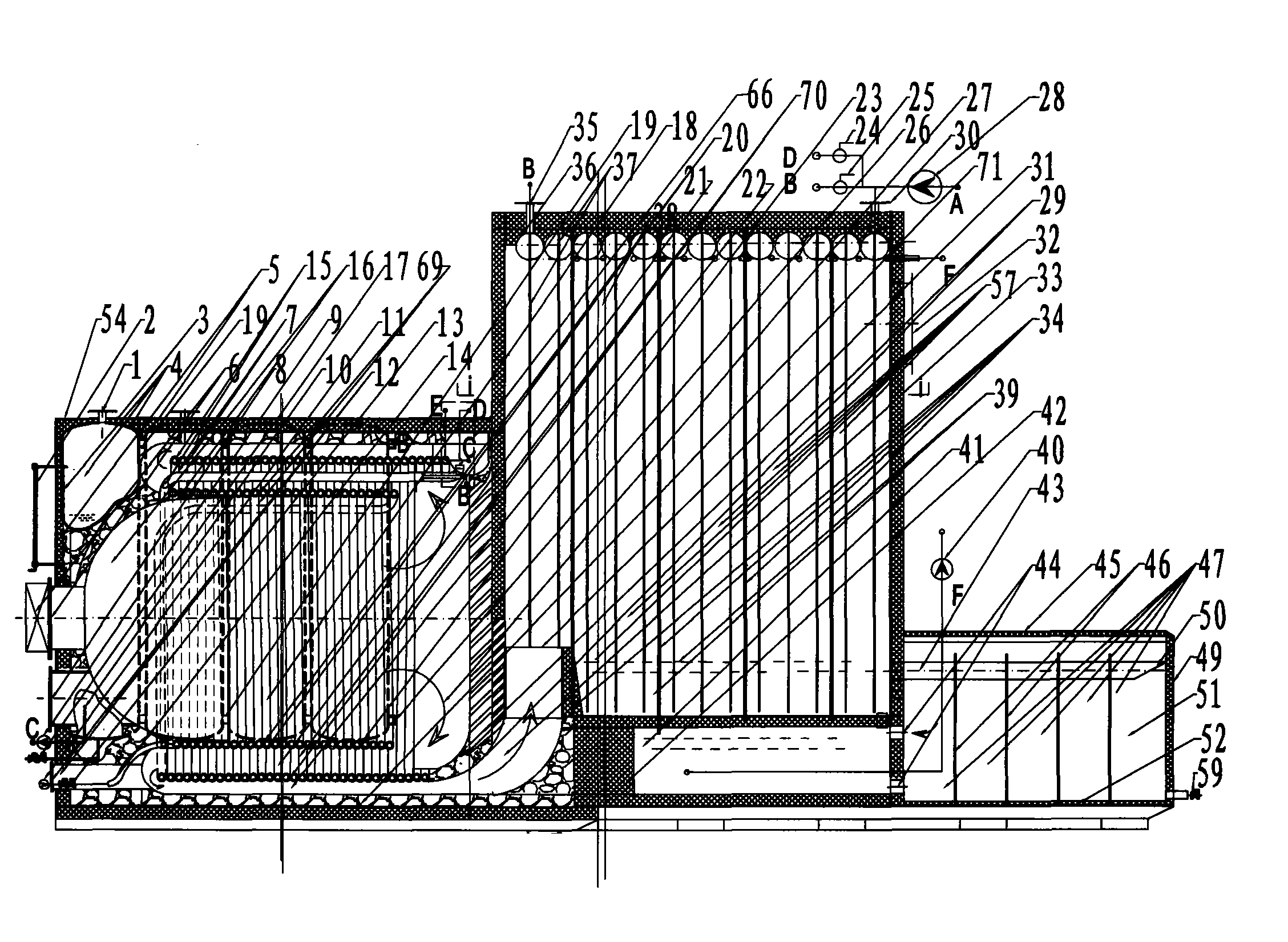

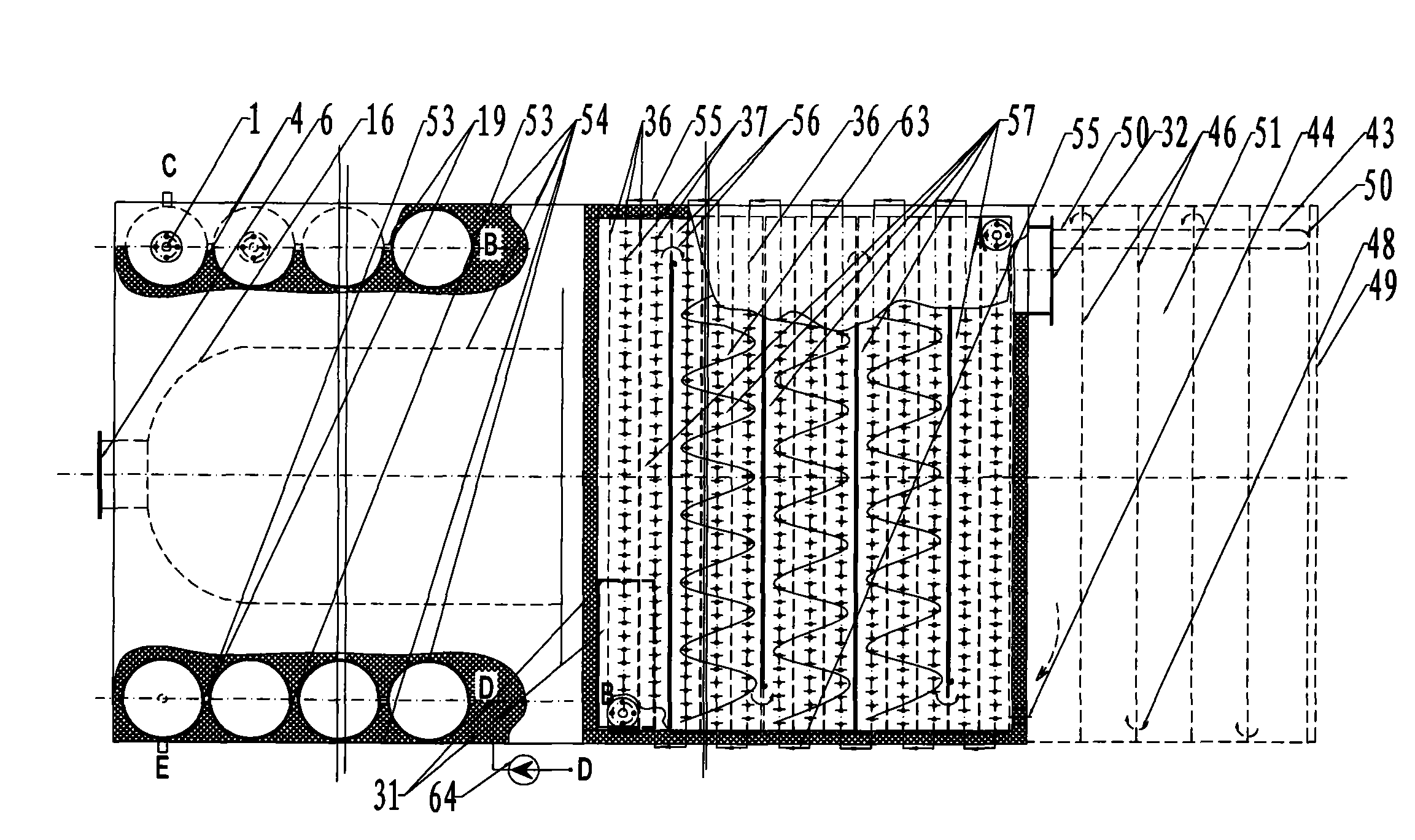

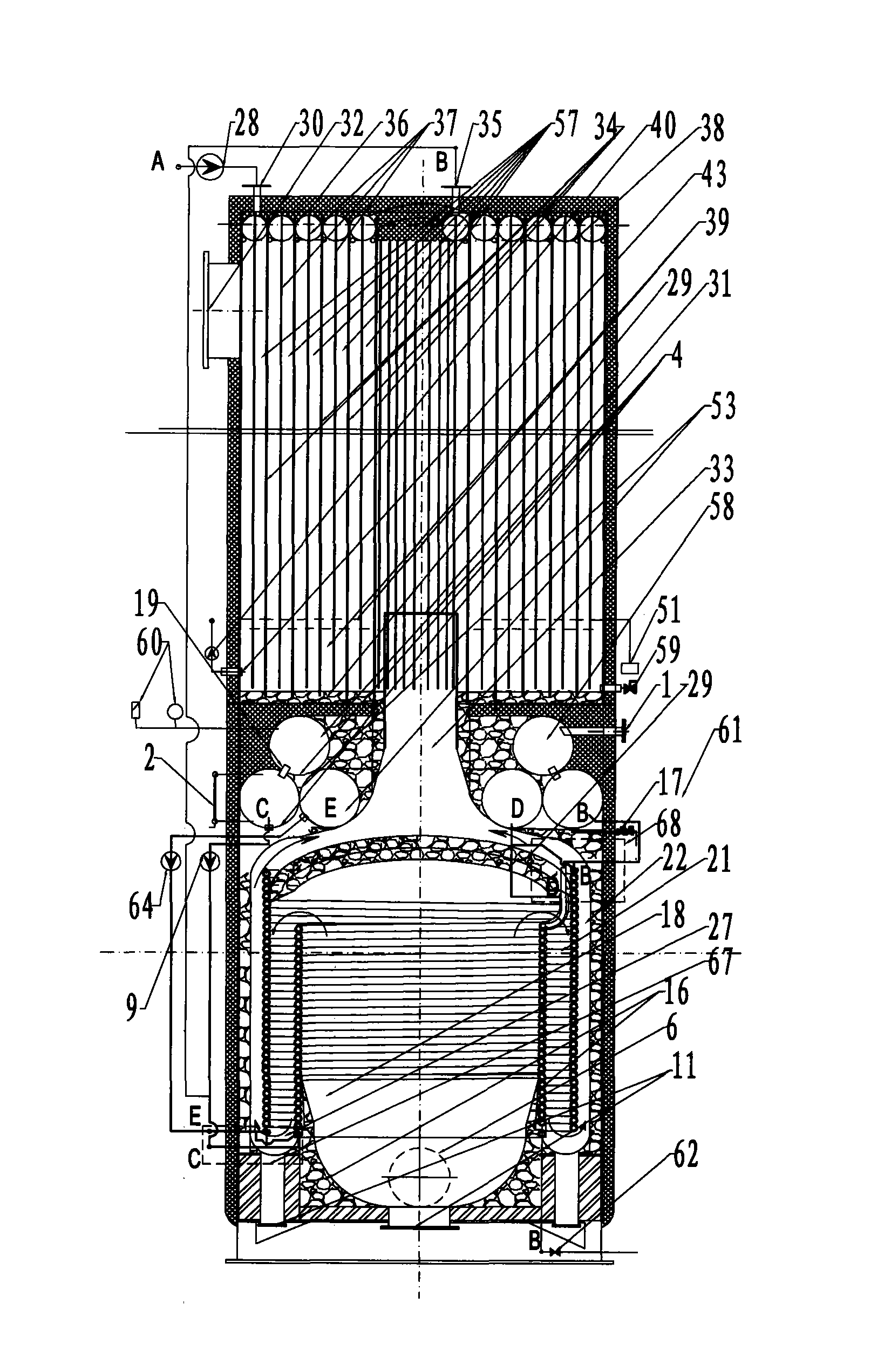

[0012] exist figure 1 Middle, middle, high and low, three sets of coil boilers 54, heat pipe heat exchange boxes 65, and return heat and overflow water sedimentation tank 49 are partly formed in the ring protection body of the three square structure insulation layers 5. The boiler 54 is composed of an outer coil 20, the tube 20 is the inner cylinder 69 formed by the double coils 20 in the outer sleeve 7 and the inner sleeve 15, which spirally extends from the front to the rear and connects to the ring. The concentric outer cylinder 70 is formed by spiraling and extending the space, and the concentric flue chamber 71 of the outer wall of the refractory concrete furnace 54 is also left outside the cylinder 70, forming the main structure of the three-pass flue. The inner ring of the flue chamber 71 is connected by the furnace wall 29 at the top of the lateral junction behind the outer cylinder 70, and the outer edge of the top is slightly behind the top of the lateral junction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com