Device and method for measuring internal and external diameters of transparent glass bottleneck based on machine vision

A machine vision and measuring device technology, applied in measuring devices, optical devices, instruments, etc., can solve the problem of inability to obtain the inner and outer diameter of the bottle mouth, etc., to avoid the interference of external ambient light, easy to popularize and apply, and avoid errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

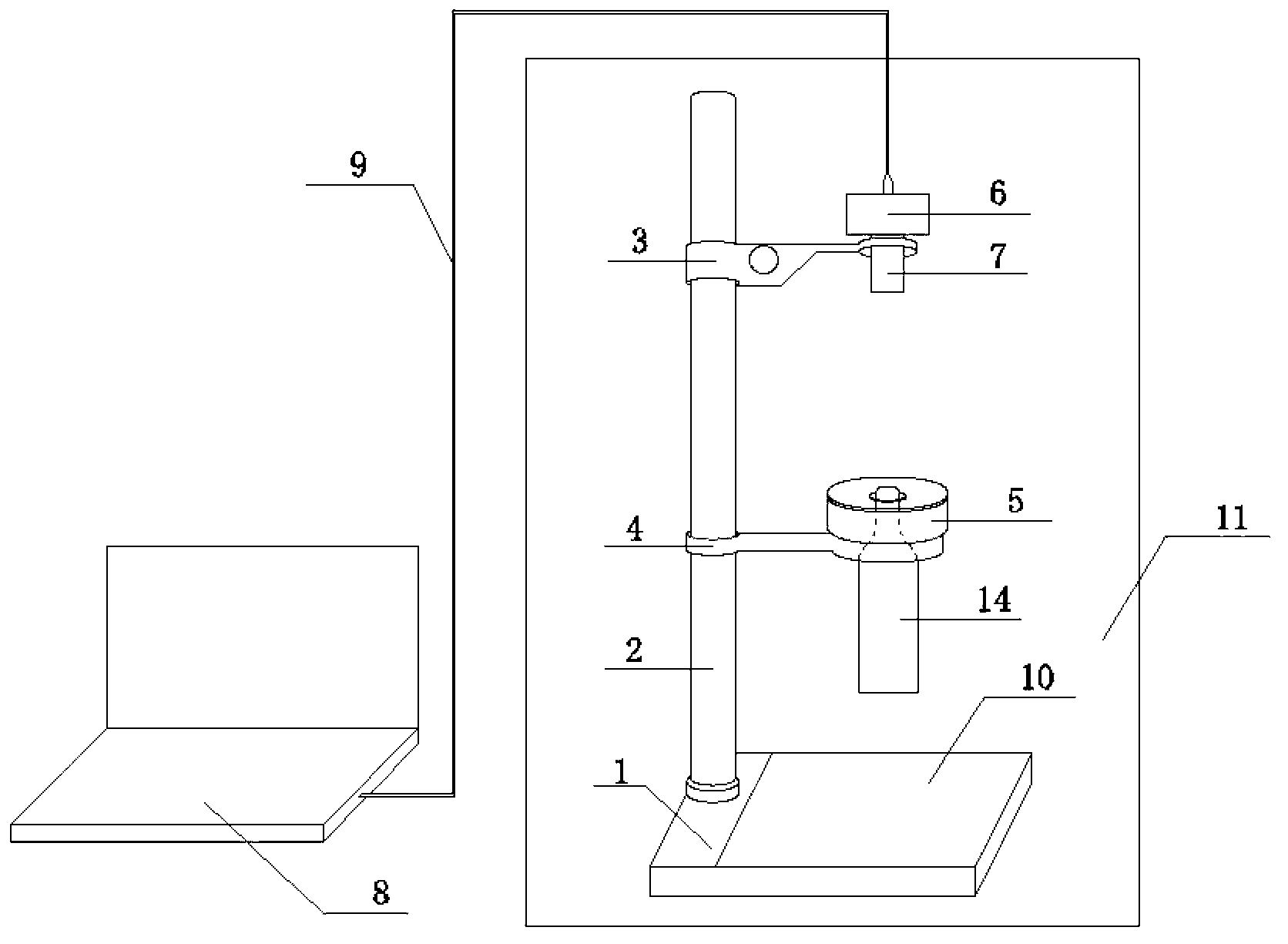

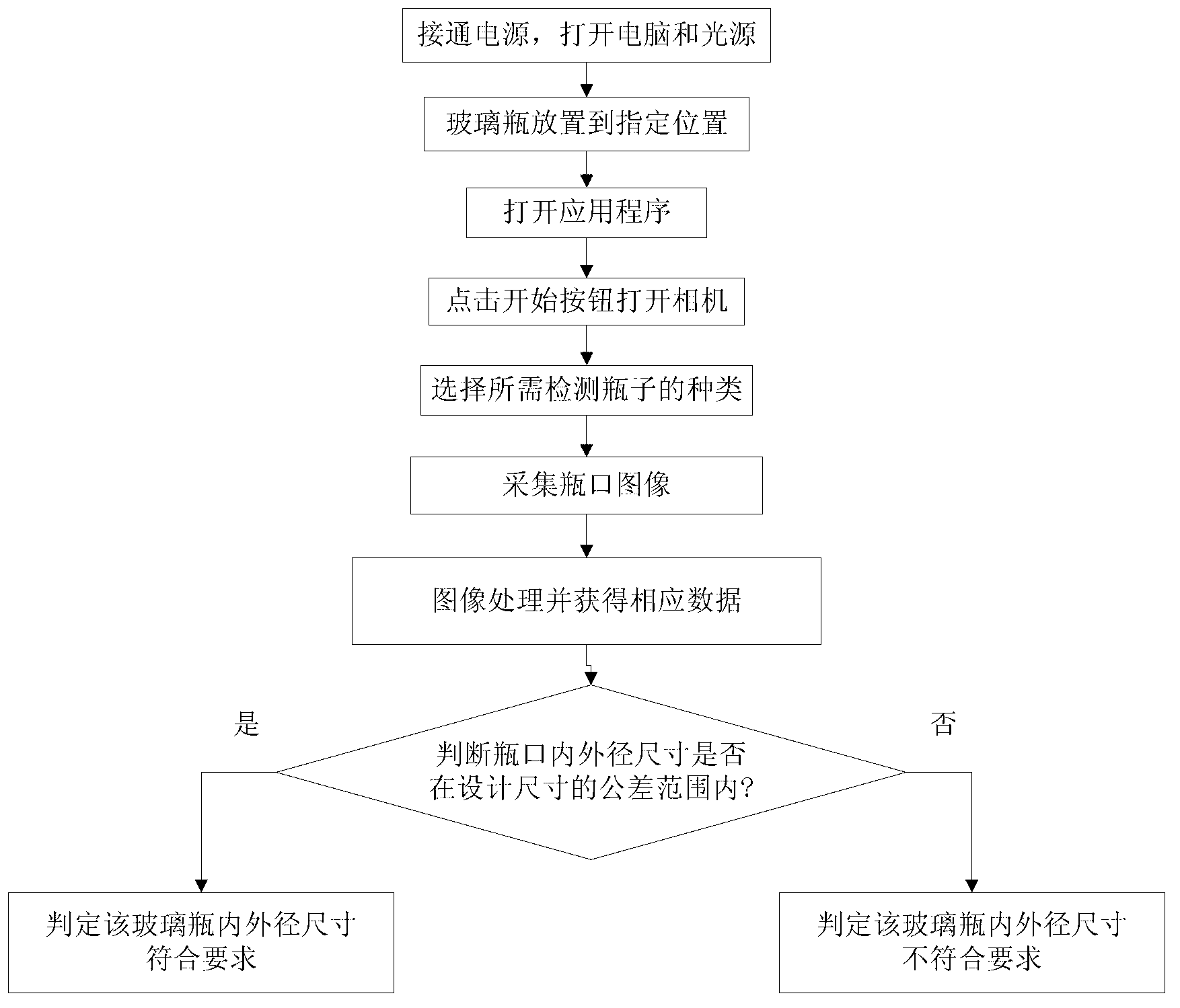

[0049] A machine vision-based measuring device for the inner and outer diameters of transparent glass bottle mouths of the present invention is as follows: figure 1 As shown, the measurement device consists of two parts: hardware device and software system. It is characterized in that the hardware device is composed of four modules: an instrument support, a light source and related accessories, an image acquisition device, and a computer system.

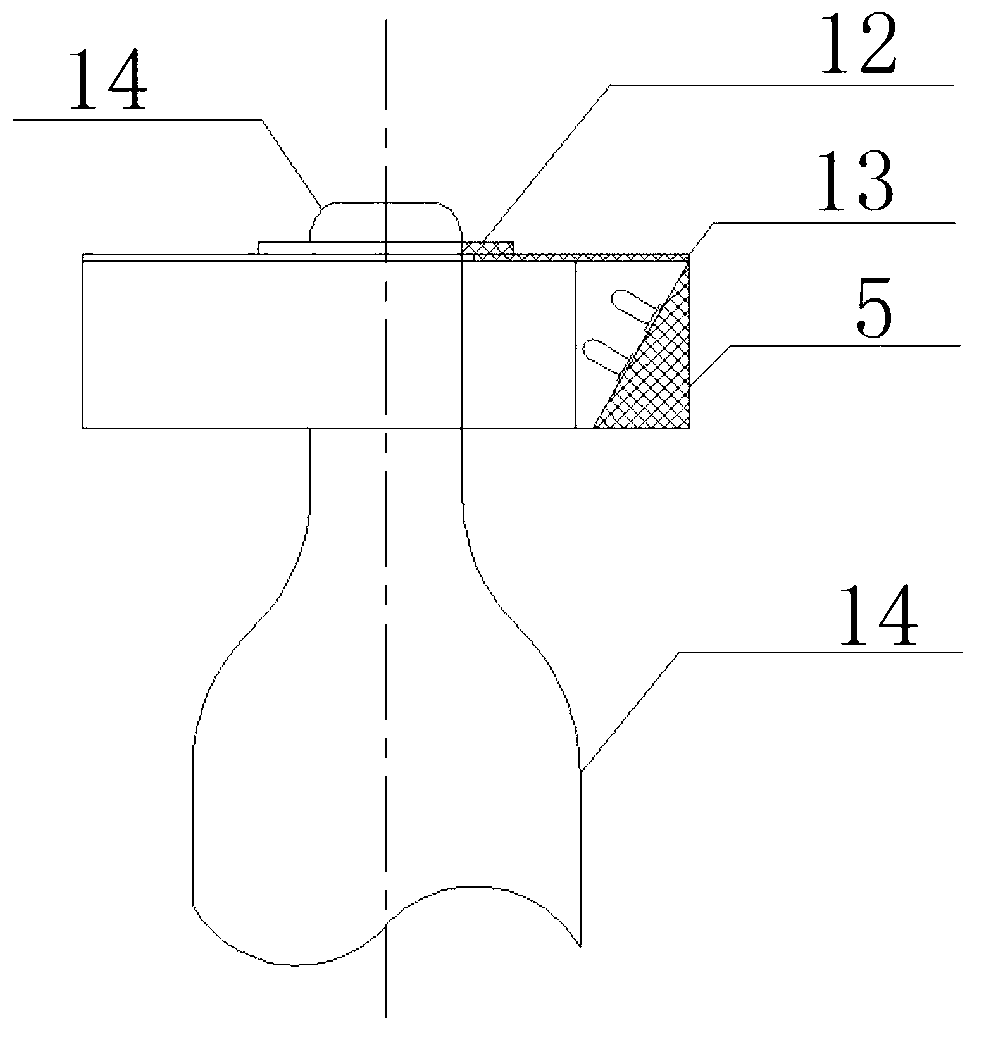

[0050] The instrument bracket includes a bracket tube 2 installed on the bracket base 1, and a camera frame 3 and a light source frame 4 are installed on the bracket tube, wherein the distance between the camera frame and the light source frame is a fixed size; the light source 5 is fixed on the light source frame upwards On the top, the black baffle 13 is fixed above the light source; the image acquisition device camera 6 and the lens 7 are fixed on the camera frame, the computer 8 and the camera 6 are connected together through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com