Base-movable aeroengine dual-rotor system model experiment platform

A technology of aero-engine and system model, which is applied in the field of aero-engine and can solve problems such as single function and inability to effectively simulate rotor system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in combination with specific embodiments.

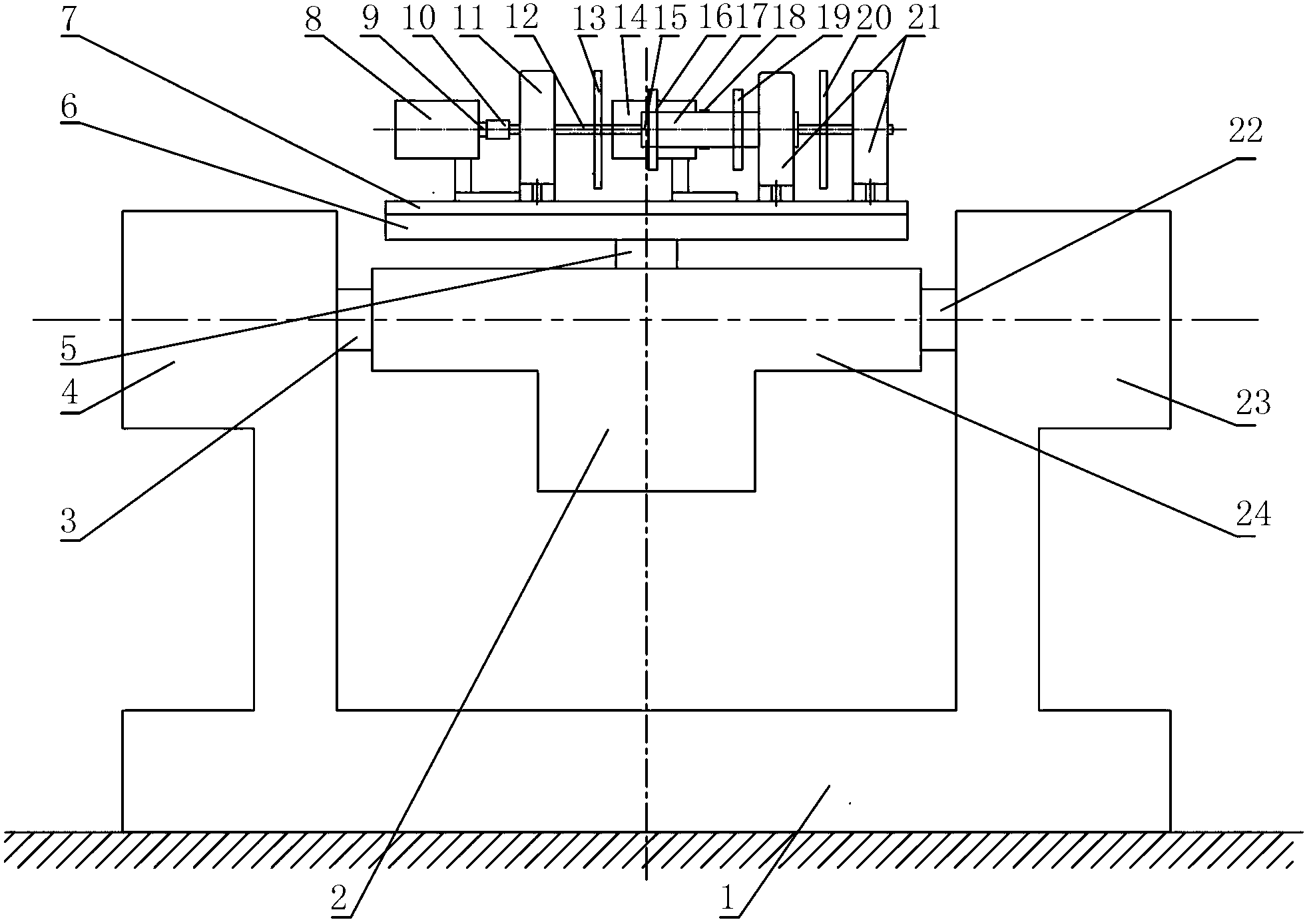

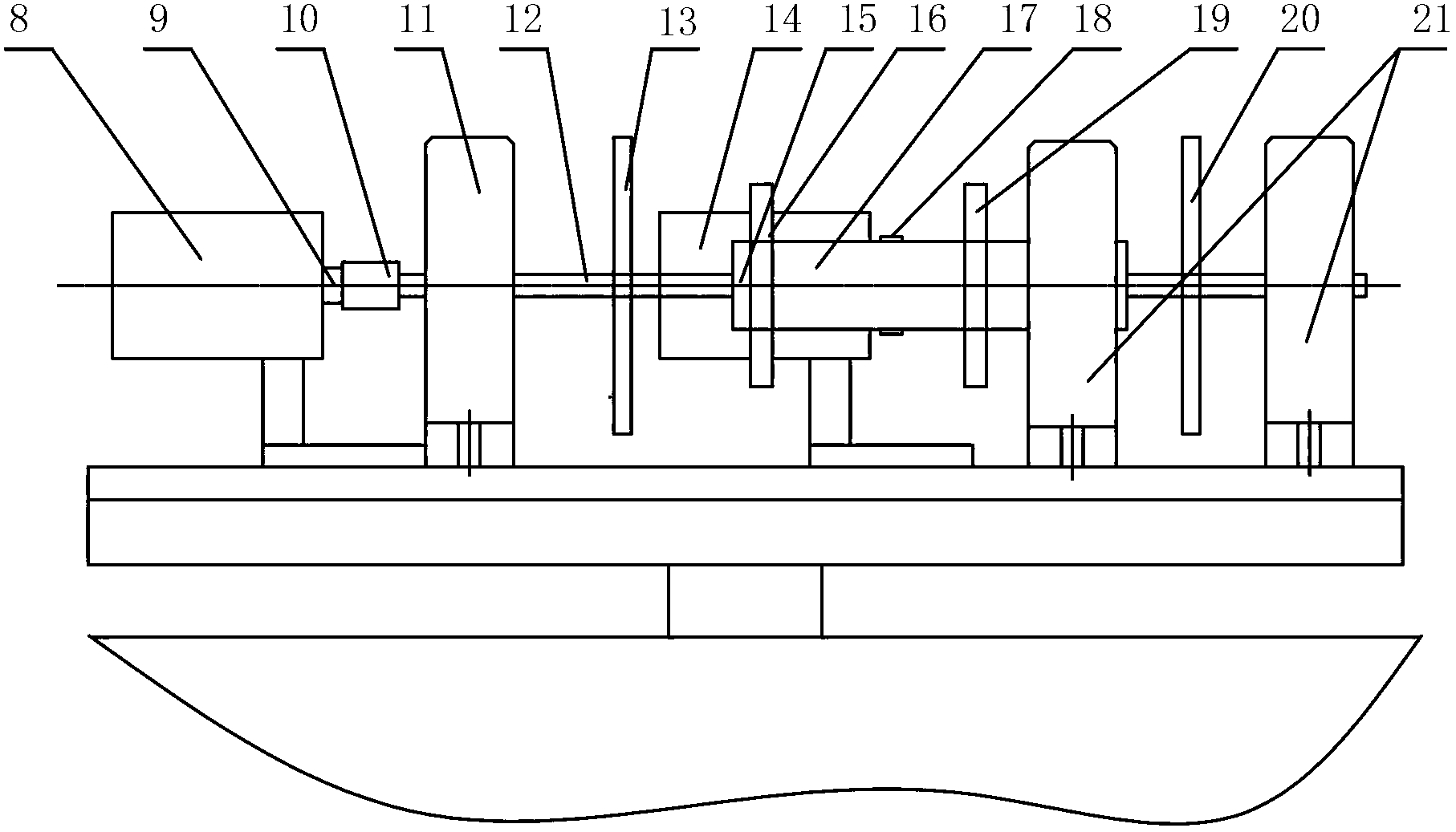

[0034] Such as figure 1 and figure 2 As shown, a basic motion aero-engine dual-rotor system model test bench of the present invention includes a basic turntable base 1 fixed on the ground, and the basic turntable base 1 is provided with a coaxial pitch transmission shaft A3 and a pitch transmission shaft B22, a basic turntable support 24 is supported between the pitch transmission shaft A3 and the pitch transmission shaft B22, a main transmission shaft 5 is arranged on the basic turntable support 24, and a basic turntable 6 is fixed on the main transmission shaft 5.

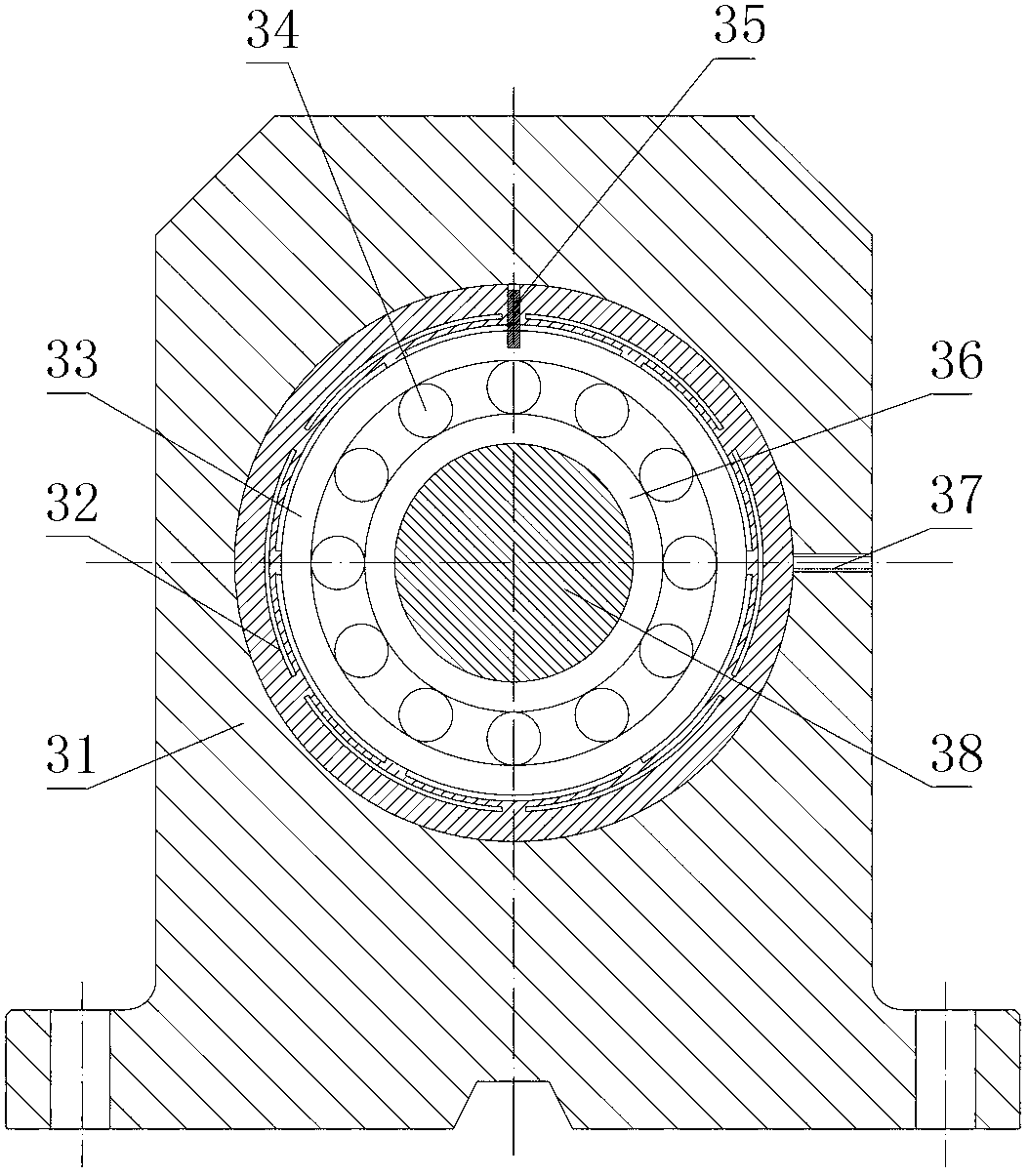

[0035] It also includes internal and external dual rotor systems, such as figure 2As shown, the internal and external dual-rotor system includes a dual-rotor system test bench base 7 fixed to the basic turntable 6, an inner rotor 12, an outer rotor 17, a bearing seat A, a bearing seat B, a bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com