High-temperature and high-pressure single-drop evaporating and burning device

A high temperature and high pressure, combustion device technology, applied in fuel testing, material inspection, etc., can solve the problem of inability to study the evaporation and combustion characteristics of tiny droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above objectives, features and advantages of this application more obvious and understandable, the application will be further described in detail below with reference to the drawings and specific implementations. The "left side" and "right side" in the following content only represent the present Apply for the "left" and "right" of the position shown in the examples.

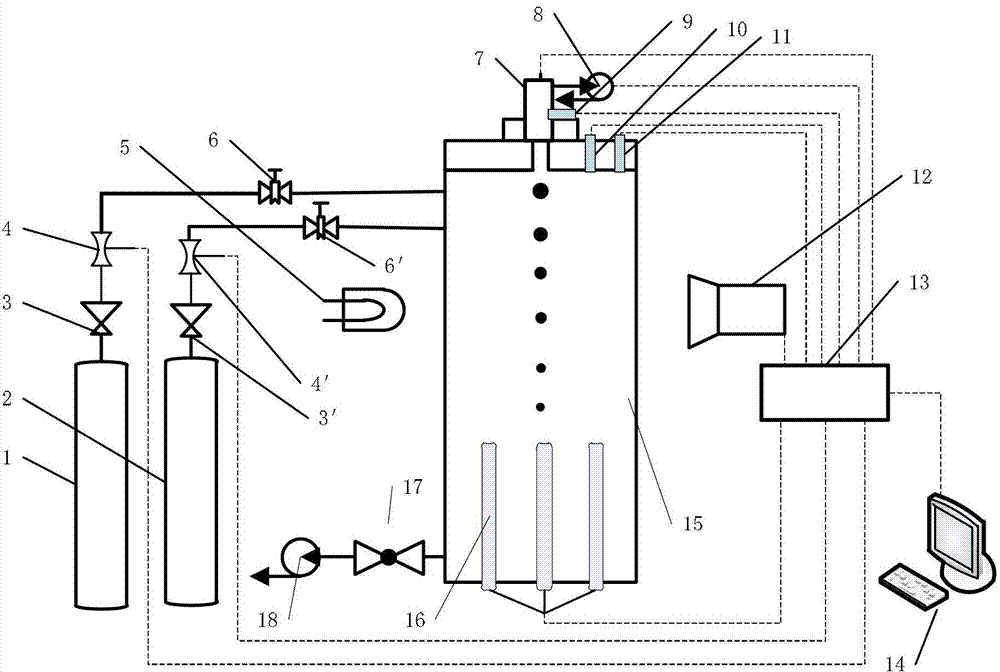

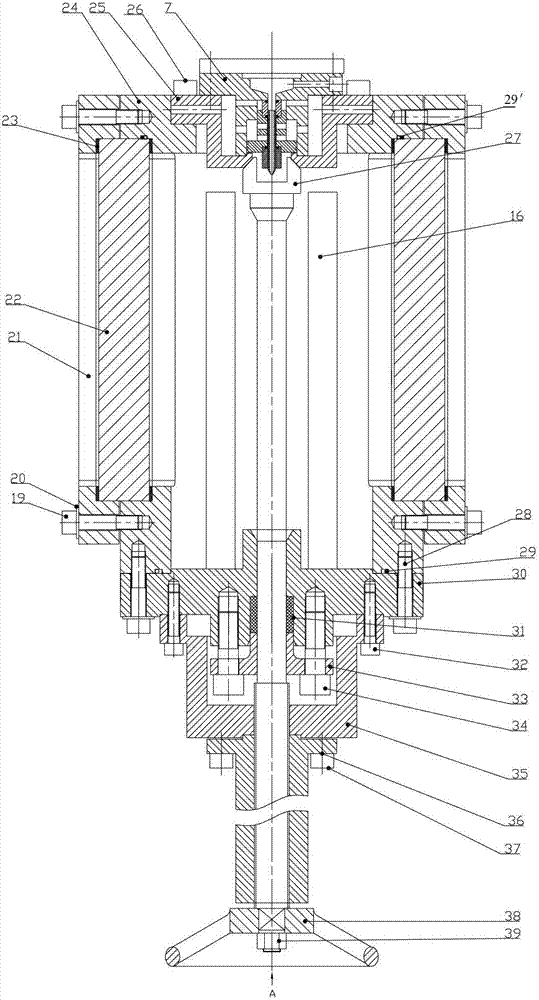

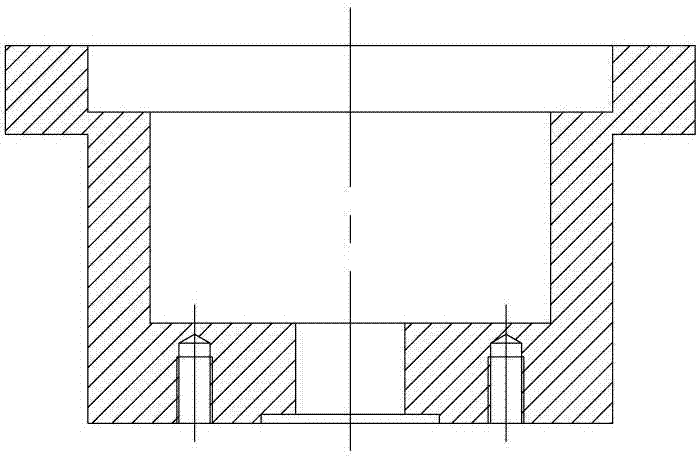

[0030] figure 1 It is a schematic structural diagram of a high-temperature and high-pressure single droplet evaporation and combustion device according to an embodiment of the present application. Such as figure 1 As shown, a high-temperature and high-pressure single droplet evaporation and combustion device includes: a gas supply device, a combustion evaporation bomb 15, a single droplet generator 7, a single droplet generator cooling device, a control unit 13 and a computer 14.

[0031] In an embodiment of the present application, the air supply device includes a high-pressure air cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com