Patterned hydrogel antifouling material and preparation method thereof

A hydrogel, patterned technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve the ecological environmental hazards of chemical antifouling coatings, cannot inhibit marine biofouling, High cost and other problems, to achieve the effect of good anti-bioadhesion performance, uniform and controllable micropore size, and good oleophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

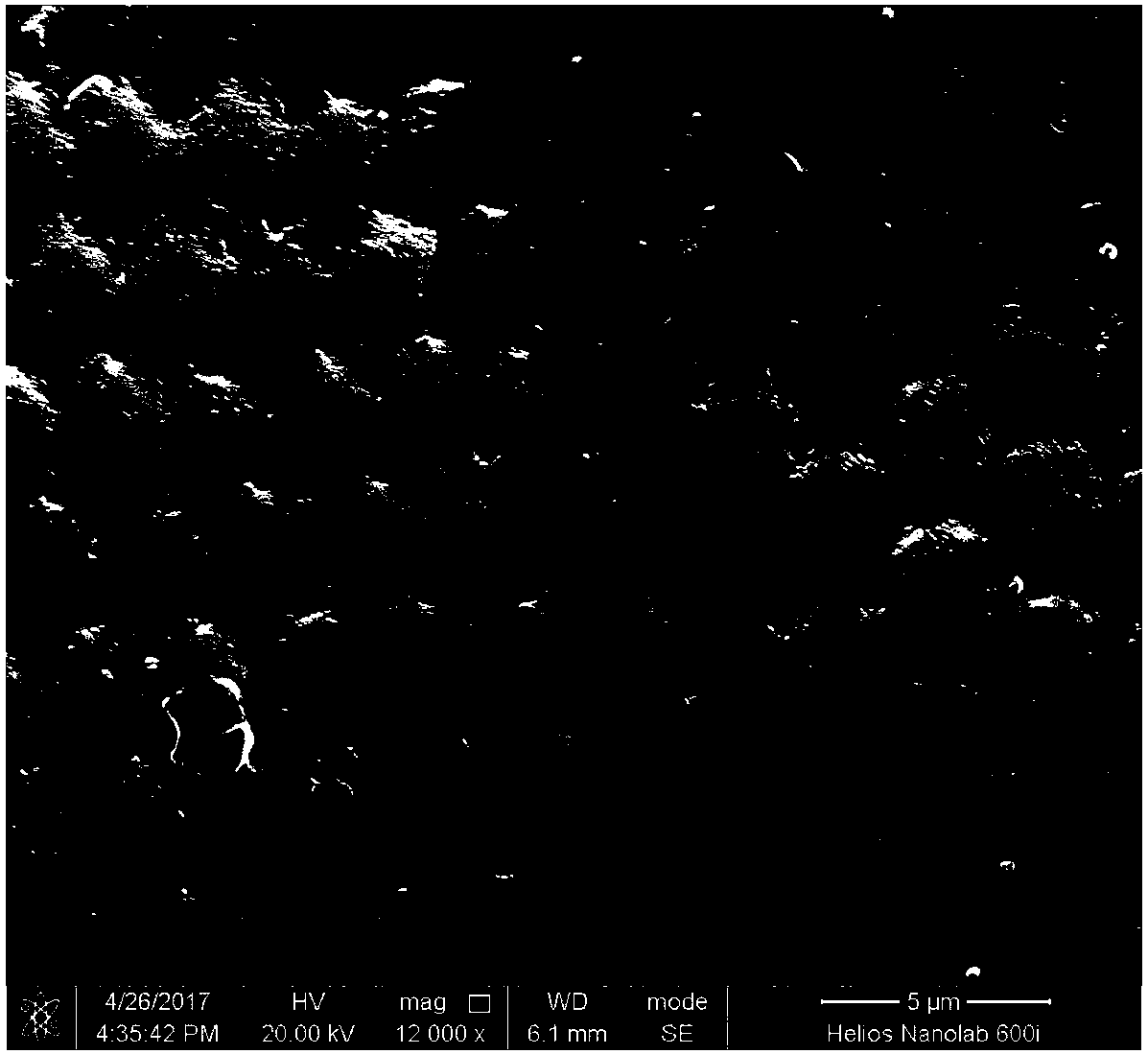

[0034] The preparation method of the patterned hydrogel antifouling material of the present invention comprises the following steps:

[0035] Step S1, using the breath template method to prepare a porous template

[0036] Prepare a solution for forming a porous template, which includes a template polymer, a surfactant P123 with a concentration of 0.2-2 mg / mL and an organic solvent; use the breathing template method to obtain a porous template with a honeycomb patterned structure, and the reaction temperature is 25 ° C to 30 ° C , the relative humidity is 20 to 40%; preferably, the template polymer is polystyrene with a molecular weight of 200,000 to 500,000 Daltons, its concentration is 3 to 15 mg / mL, and the organic solvent is chloroform; preferably, the template polymer The compound is polylactic acid-glycolic acid copolymer with a molecular weight of 40000-60000 daltons, its concentration is 10-20% (w / v), and the organic solvent is dichloromethane.

[0037] Step S2, prepar...

Embodiment 1

[0047] The preparation method of the patterned hydrogel antifouling material of the present embodiment comprises the following steps:

[0048] Step S1, using the breath template method (Breath Figure) to prepare a porous template

[0049] Prepare a polystyrene porous template by using the breath template method (Breath Figure), configure a solution to form a porous template, wherein the molecular weight of polystyrene is 350,000 Daltons, the concentration is 6.0 mg / mL, and the concentration of surfactant P123 is 0.5 mg / mL, chloroform as a solvent; the porous template of the honeycomb patterned structure is obtained by the breathing template method, the reaction temperature is 25°C-30°C, and the relative humidity is 20-40%.

[0050] Step S2, preparing a double network nanocomposite hydrogel on the porous template prepared in step S1

[0051] Configuration precursor solution, wherein chitosan 2.0wt%, glacial acetic acid 1.0wt%, acrylamide 24.0wt%, N,N'-methylenebisacrylamide 0...

Embodiment 2

[0059] The preparation method of the patterned hydrogel antifouling material of the present embodiment comprises the following steps:

[0060] Step S1, using the breath template method (Breath Figure) to prepare a porous template

[0061] Prepare a polystyrene porous template by the Breath Figure method, configure a solution to form a porous template, wherein the molecular weight of polystyrene is 200,000 Daltons, the concentration is 15.0 mg / mL, and the concentration of surfactant P123 is 2.0 mg / mL , chloroform is used as a solvent; a porous template with a honeycomb patterned structure is obtained by a breathing template method, the reaction temperature is 25° C. to 30° C., and the relative humidity is 20 to 40%.

[0062] Step S2, preparing a double network nanocomposite hydrogel on the porous template prepared in step S1

[0063] Configuration precursor solution, wherein chitosan 1.0wt%, glacial acetic acid 0.2wt%, acrylamide 16.0wt%, N,N'-methylenebisacrylamide 0.005wt% a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com