Dual-mode travelling-wave tube slow-wave structure

A slow-wave structure and traveling-wave tube technology, which is applied in the field of dual-mode traveling-wave tube slow-wave structures, can solve the problems of limiting the performance and use of dual-mode traveling wave tubes, the output power cannot be very different, and it is difficult to meet requirements, etc. The effect of small difference in gain parameter C, small electric field and strong electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

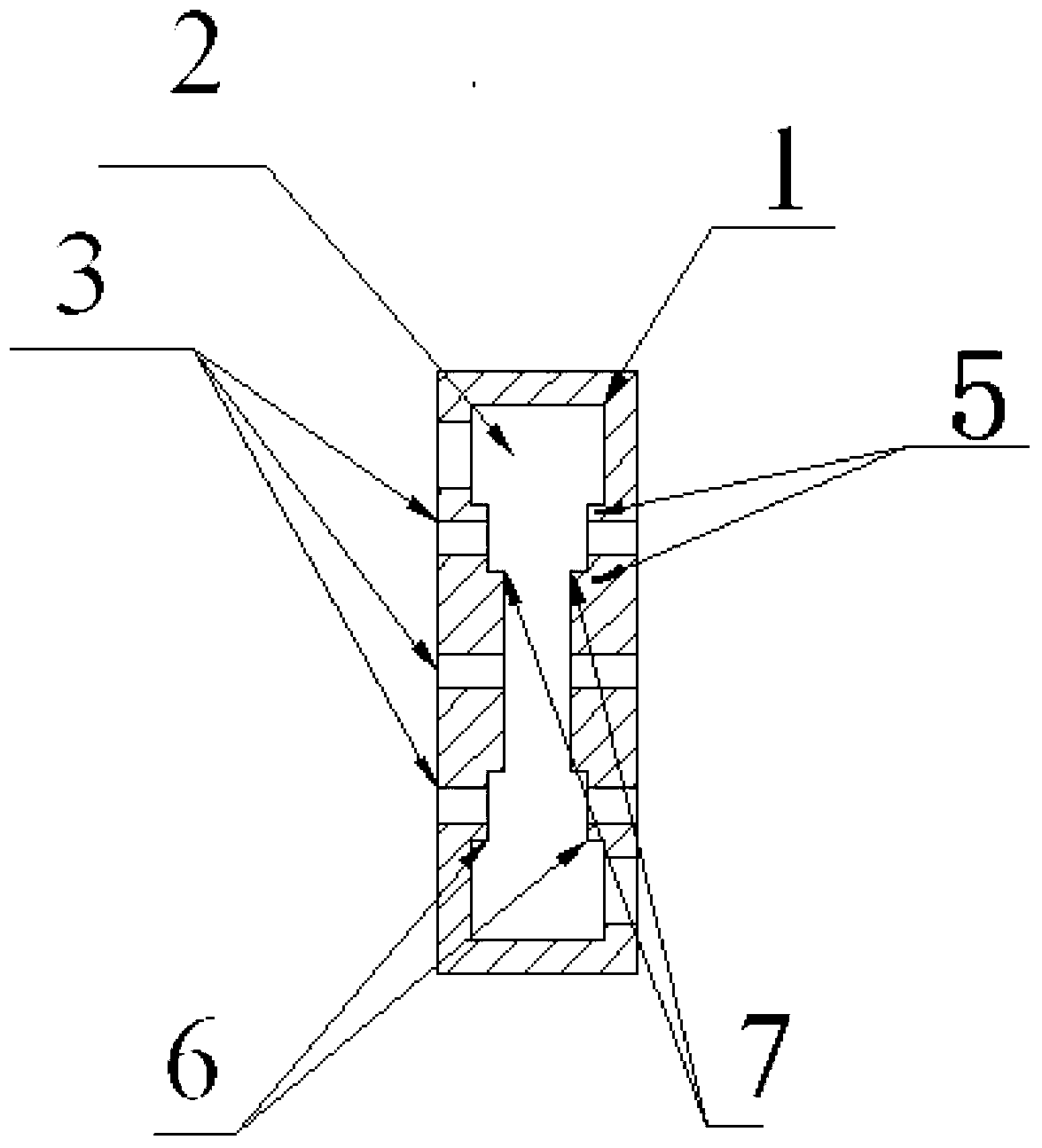

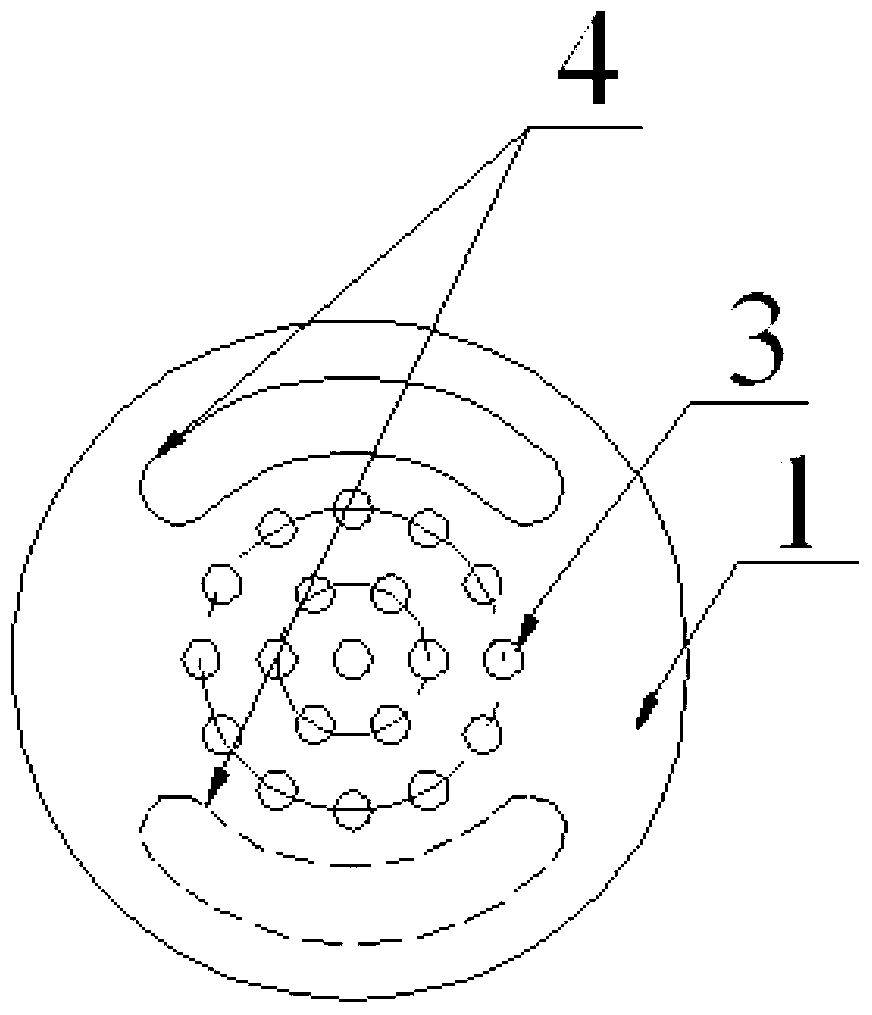

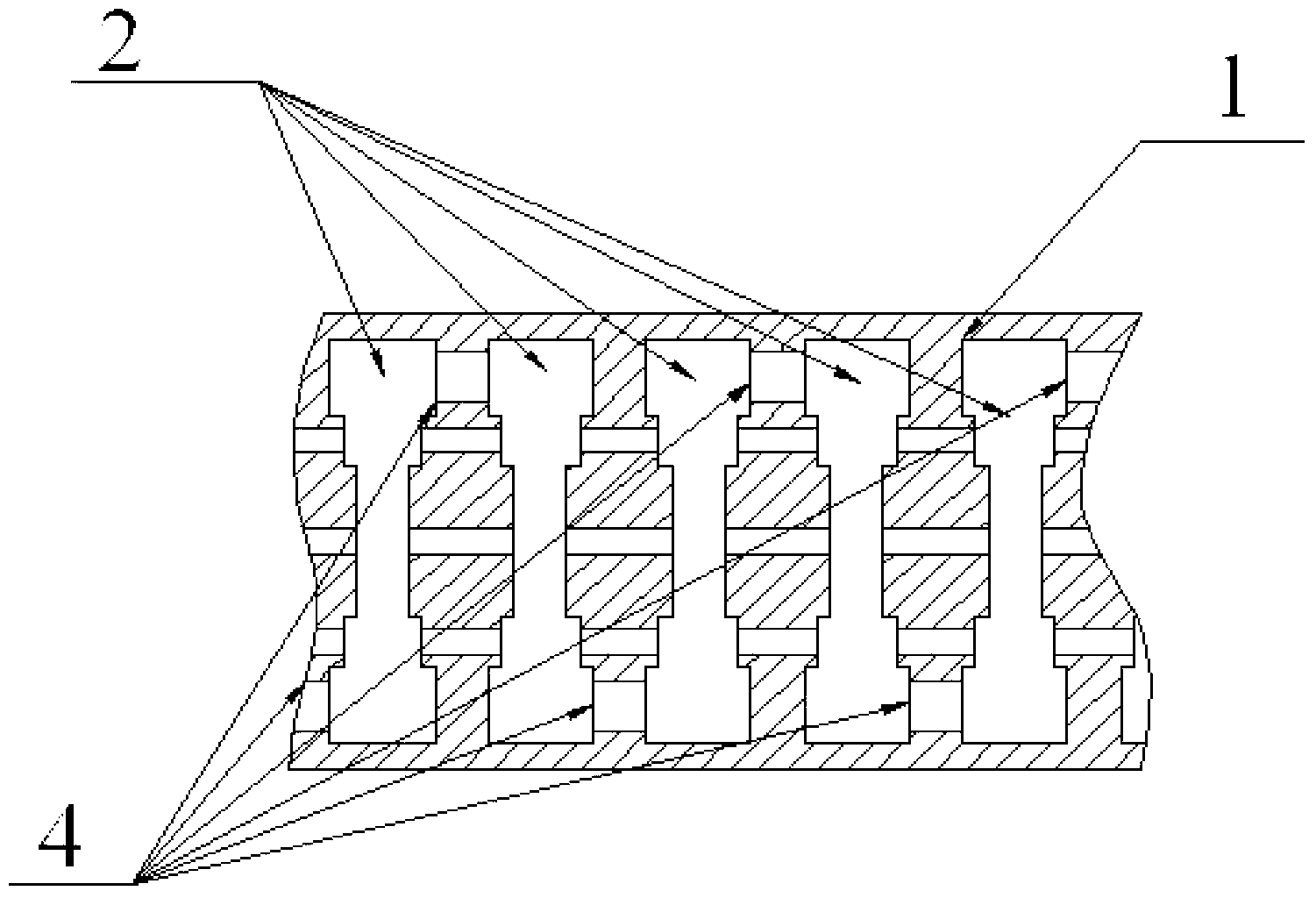

[0031] Such as figure 1 As shown, the slow-wave structure of the dual-mode traveling wave tube includes a coupling cavity 1, and an electron injection channel 3 is provided at the center of the inner wall of the coupling cavity 1 (that is, the inner cavity 2 of the coupling cavity); There is a protrusion 5, and the electron beam channel 3 is arranged on the protrusion 5; the electron beam channel 3 is arranged in turn from the center of the protrusion 5 to the edge of the protrusion 5, and there are three layers of the protrusion center layer, the middle layer and the outer layer, and the protrusion center layer , the number of electron injection channels in the middle layer and the outer layer increases in turn.

[0032] The protrusion 5 is a double-step structure, which is divided into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com