Vertical trench IGBT and method for manufacturing the same

一种制造方法、沟槽的技术,应用在半导体/固态器件制造、电气元件、电路等方向,能够解决漏电流变大、缺陷增加、RBSOA耐受性劣化等问题,达到提高耐受性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

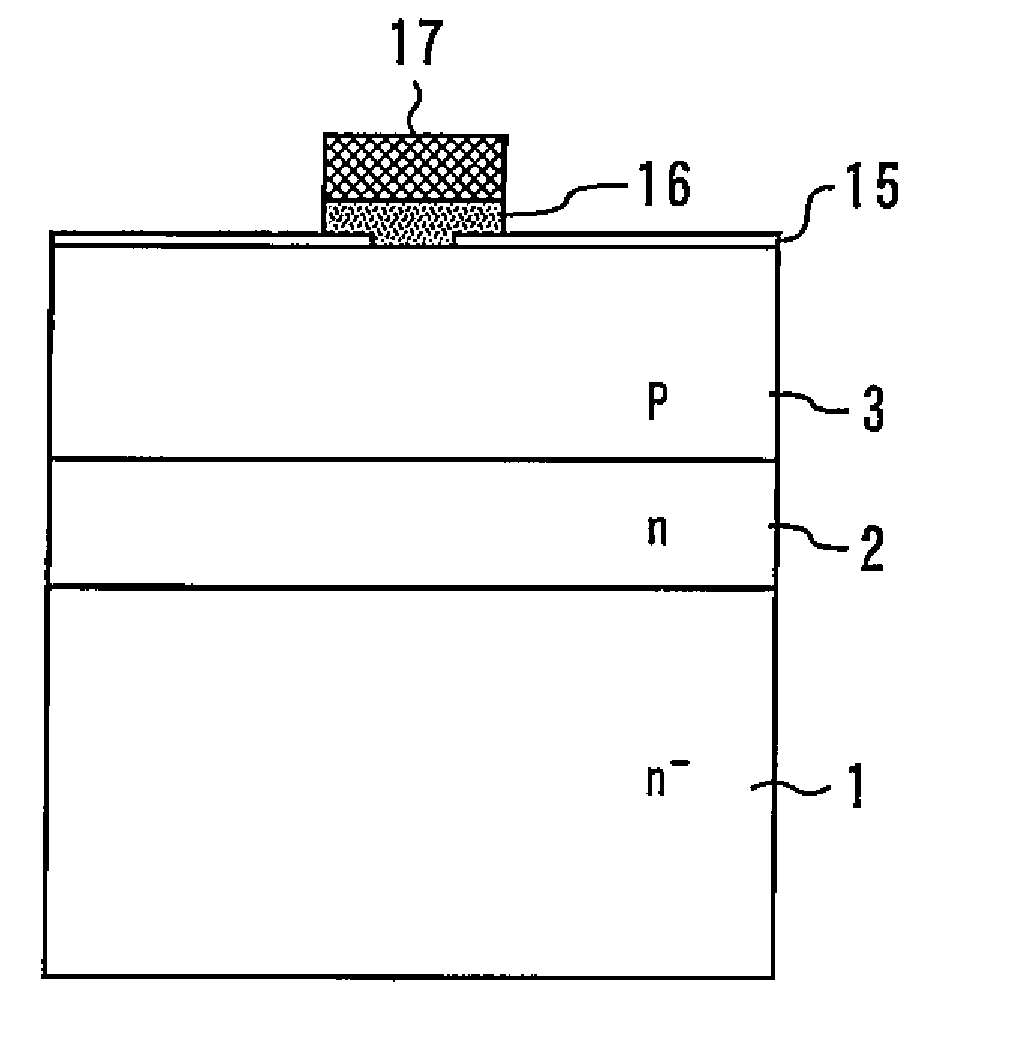

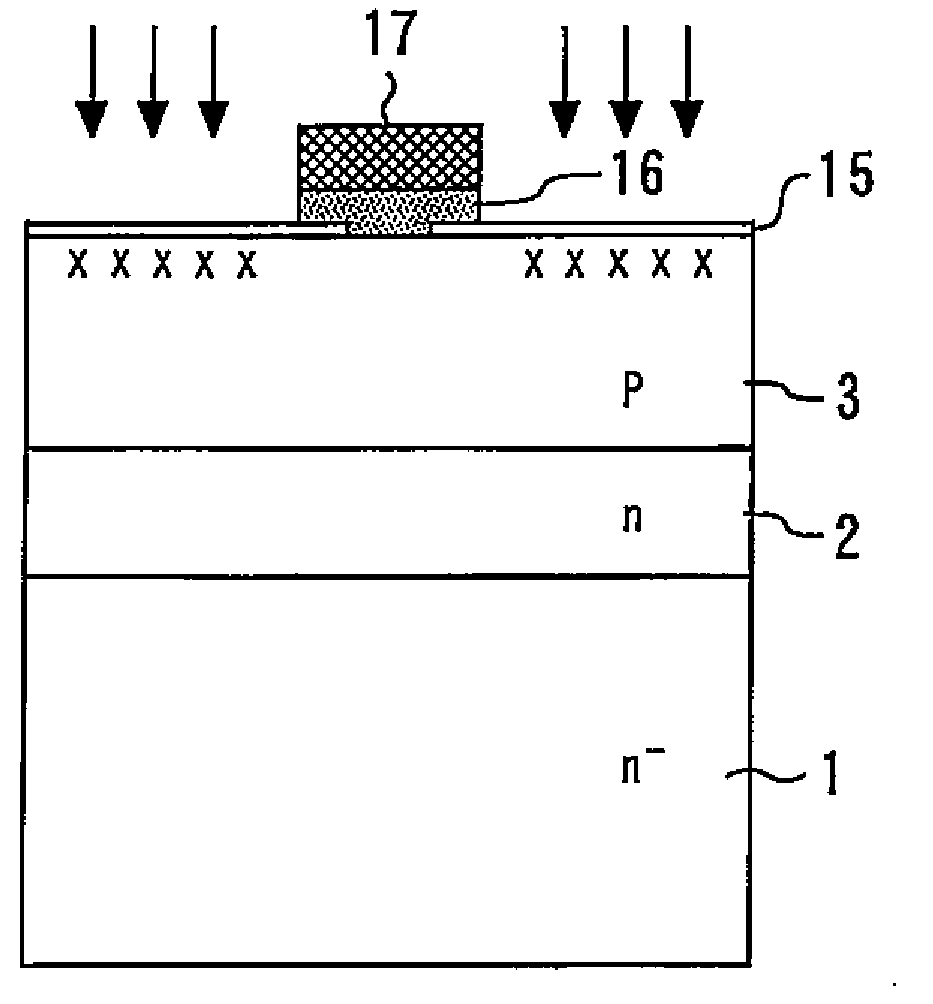

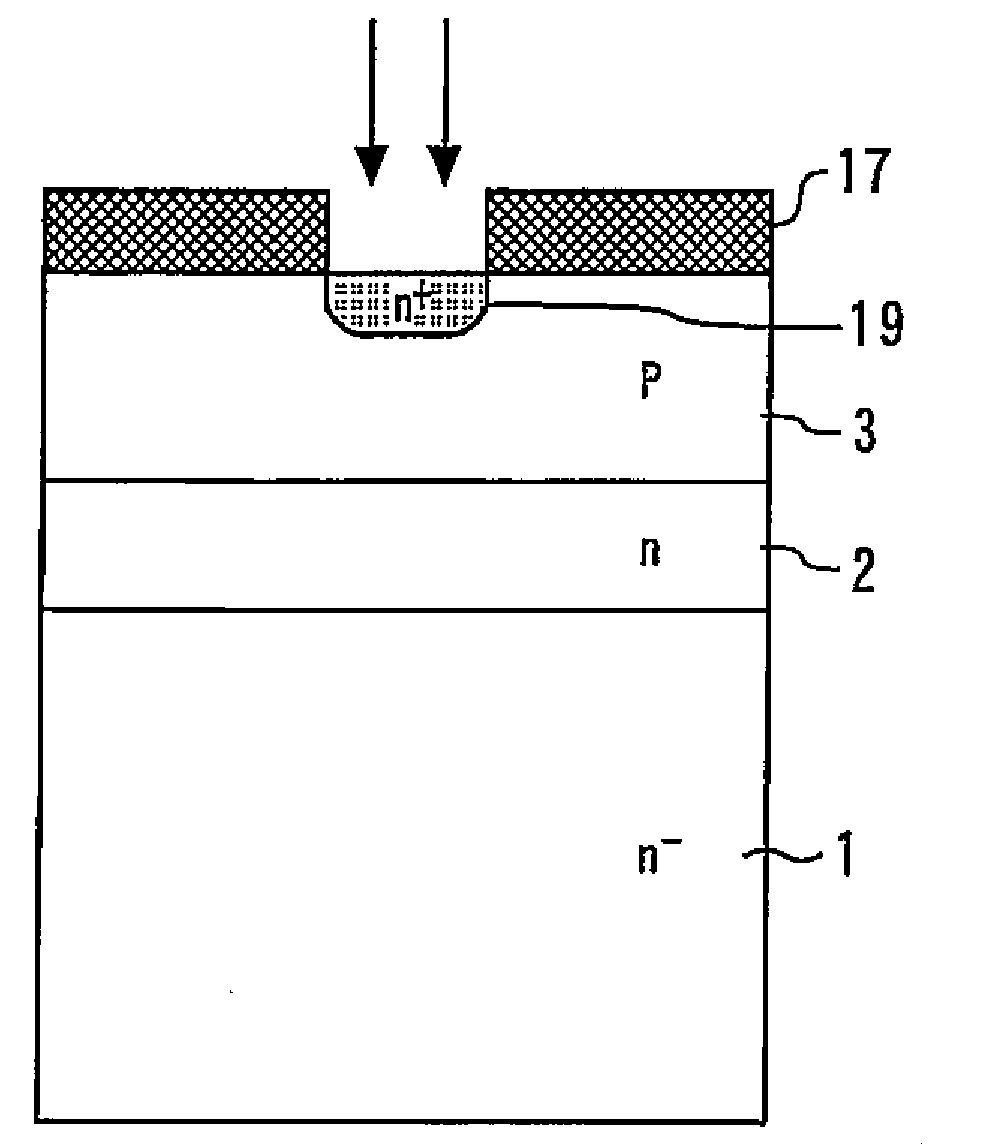

[0032] figure 1 is a perspective view showing the vertical trench IGBT according to Embodiment 1 of the present invention, figure 2 is along figure 1 Cross section of A-A'. in n - An n-type charge storage layer 2 and a p-type body layer 3 are sequentially disposed on an n-type Si substrate 1 . A trench gate 4 is provided in a trench penetrating the p-type body layer 3 via a gate insulating film 5 . Trench gates 4 are arranged in stripes in plan view.

[0033] An n-type emitter layer 6 and a p+-type diffusion layer 8 are provided on the p-type body layer 3 . In plan view, n-type emitter layers 6 and p+-type diffusion layers 8 are alternately arranged between adjacent trench gates 4 in the longitudinal direction of trench gates 4 .

[0034] Interlayer insulating film 9 covers trench gate 4 . Emitter electrode 10 is provided on interlayer insulating film 9 . Contact plug 11 penetrates interlayer insulating film 9 and connects p-type body layer 3 and n-type emitter layer ...

Embodiment approach 2

[0046] Figure 14 It is a perspective view showing a vertical trench IGBT according to Embodiment 2 of the present invention. Figure 15 is along Figure 14 Cross section of A-A'. A polysilicon film 20 having a film thickness of 500 Å to 5000 Å is provided between the p-type body layer 3 , the n-type emitter layer 6 , and the contact plug 11 .

[0047] The polysilicon film 20 can reduce the stress caused by the trench gate 4 and the contact plug 11 in the microcell. Accordingly, it is possible to suppress the increase of defects in the Si substrate. As a result, the junction leakage current is reduced, so that the RBSOA tolerance can be improved.

[0048] In Embodiments 1 and 2, it is preferable to form polysilicon films 16 and 20 simultaneously with polysilicon forming trench gate 4 , polysilicon forming polysilicon electrode 21 of a poly-poly capacitor, polysilicon resistor 22 , and the like. Thereby, the number of steps can be reduced.

[0049] In addition, the vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com