Thin film photoconductive detector and manufacturing method and application thereof

A detector and photoconductive technology, applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, electric solid-state devices, etc., can solve the problems of poor performance of one-dimensional nano-devices, achieve high responsivity, simple preparation method, and improve responsivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

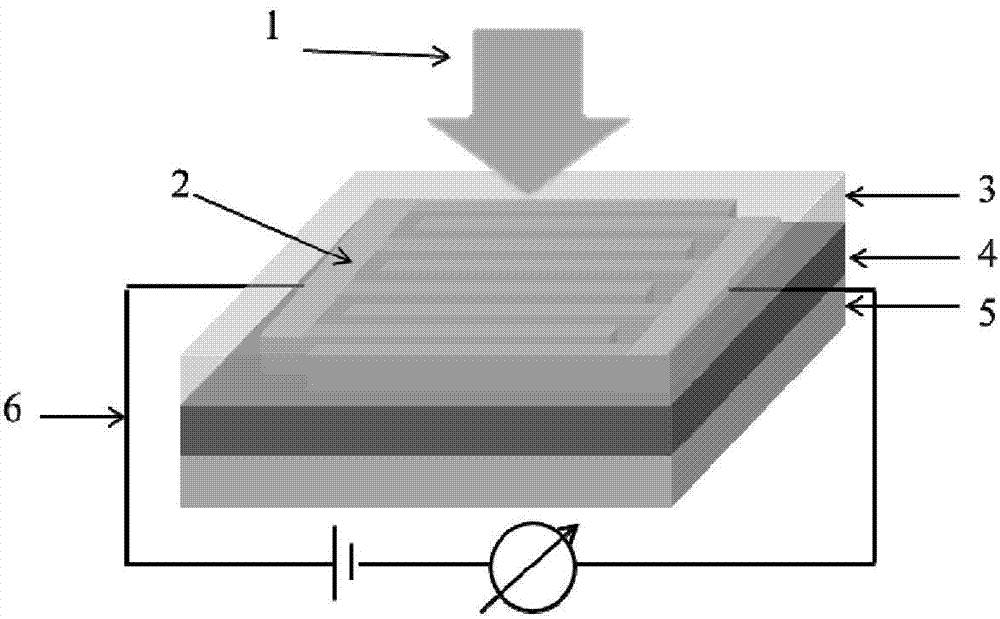

[0055] 1) if figure 1 As shown, zinc acetate was dissolved in methoxyethanol to obtain a solution with a concentration of 40mg / ml, spin-coated at 1000rpm for 60s on a glass substrate 5 with a thickness of 3mm and annealed at 500°C for 1h to obtain a carrier transport layer 4 with a thickness of 50nm .

[0056] The material constituting the carrier transport layer is zinc oxide;

[0057] 2) On the carrier transport layer obtained in step 1), the positive electrode layer 2 and the negative electrode layer 2 were respectively vacuum evaporated, the length of the positive electrode and the negative electrode was 8800 μm, the distance between the two electrodes was 80 μm, and the vacuum degree during vacuum evaporation was 1 ×10 -4 Pa.

[0058] Both the positive electrode layer and the negative electrode layer are made of aluminum;

[0059] The thickness is 50nm;

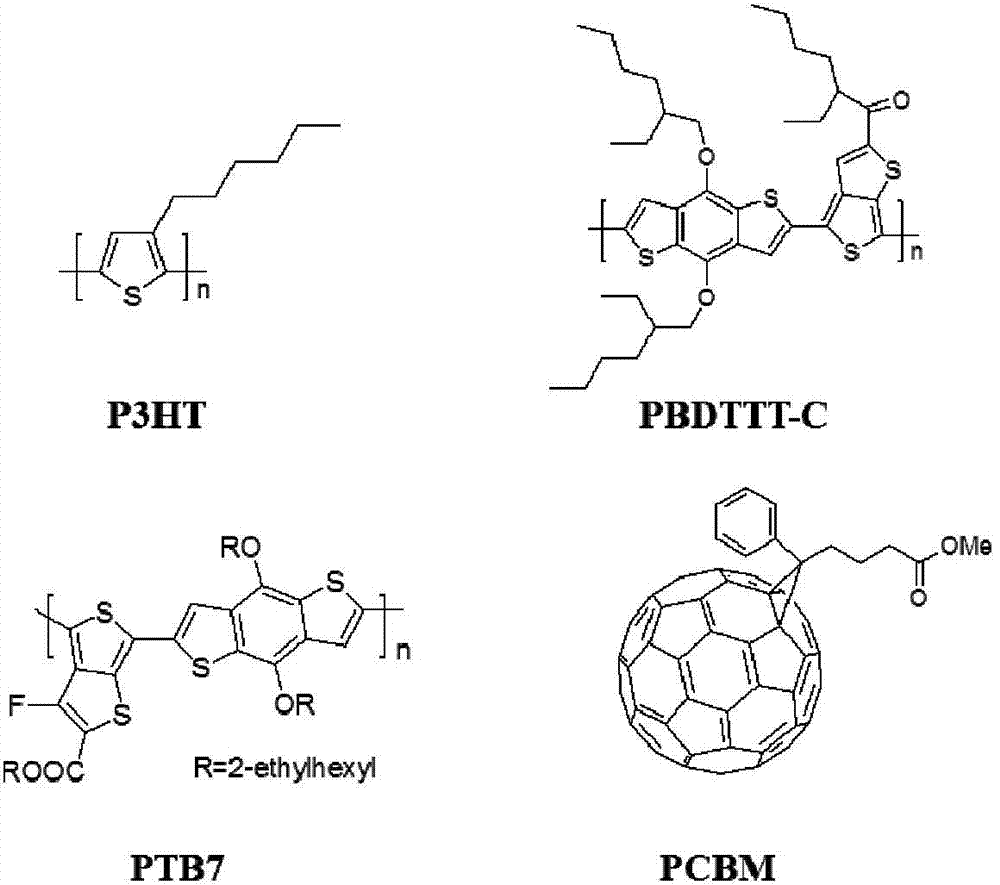

[0060] 3) Prepare a layer of light-absorbing layer by spin coating on the positive electrode layer and the negat...

Embodiment 2

[0071] According to the steps of embodiment 1, only step 3) is replaced by the following steps:

[0072] 3) Prepare a light-absorbing layer by spin coating on the positive electrode layer and the negative electrode layer obtained in step 2). The specific steps include: adding PBDTTT-C with a relative molecular mass of 60000g / mol and PCBM with a relative molecular mass of 910.88g / mol by weight After mixing evenly at a ratio of 1:1.5, it was dissolved in o-dichlorobenzene to obtain a solution with a concentration of 40 mg / ml. After spin coating at 1000 rpm for 60 seconds, the substrate was annealed at 100° C. for 10 minutes to obtain a light-absorbing layer 3 with a thickness of 150 nm, and obtain the present invention. Thin-film photoconductive detectors;

[0073] According to the same steps as above, only the PBDTTT-C used in step 3) is replaced with PTB7 with a relative molecular mass of 10000-60000 g / mol, and another thin film photoconductive detector provided by the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com