Acid mixing system of lead-acid storage batteries

A lead-acid battery and acid dispensing technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of low acid dispensing efficiency and uneven acid concentration distribution, and achieve the effect of ensuring efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

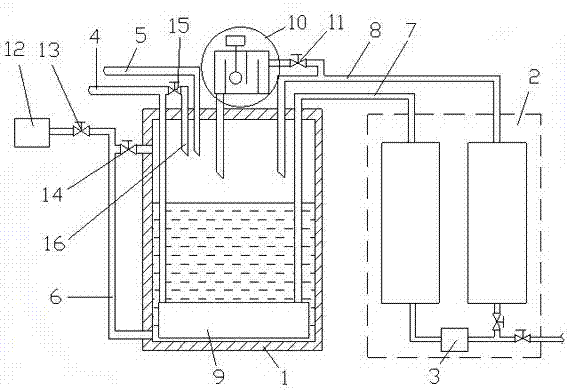

[0040] The principles and features of the present invention will be described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0041] The lead-acid battery acid dispensing system of the present invention is used to configure acid solutions for lead-acid batteries with various concentrations. It injects a predetermined volume of concentrated acid into a predetermined volume of pure water and mixes the two to obtain the acid solution of the required concentration. acid.

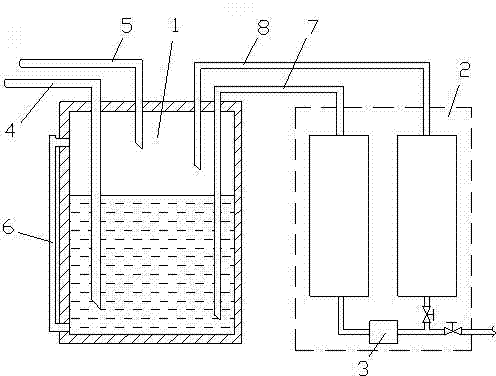

[0042] Such as figure 2 As shown, the acid dispensing system of the present invention is mainly composed of an acid dispensing tank 1 , a cooling device 2 and an acid dispensing pump 3 .

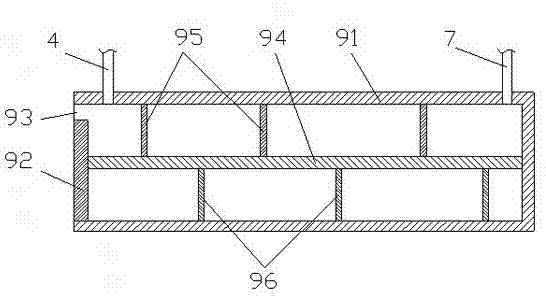

[0043] The acid distribution tank 1 is provided with an acid injection pipe 4, a water injection pipe 5, a liquid level gauge 6, an acid liquid output pipe 7, and an acid liquid retu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com