Power battery heat management method and device

A power battery and thermal management technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of high power consumption of thermal management units, lower battery performance, and large thermal management space, so as to improve thermal management efficiency and improve The effect of battery performance and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and examples.

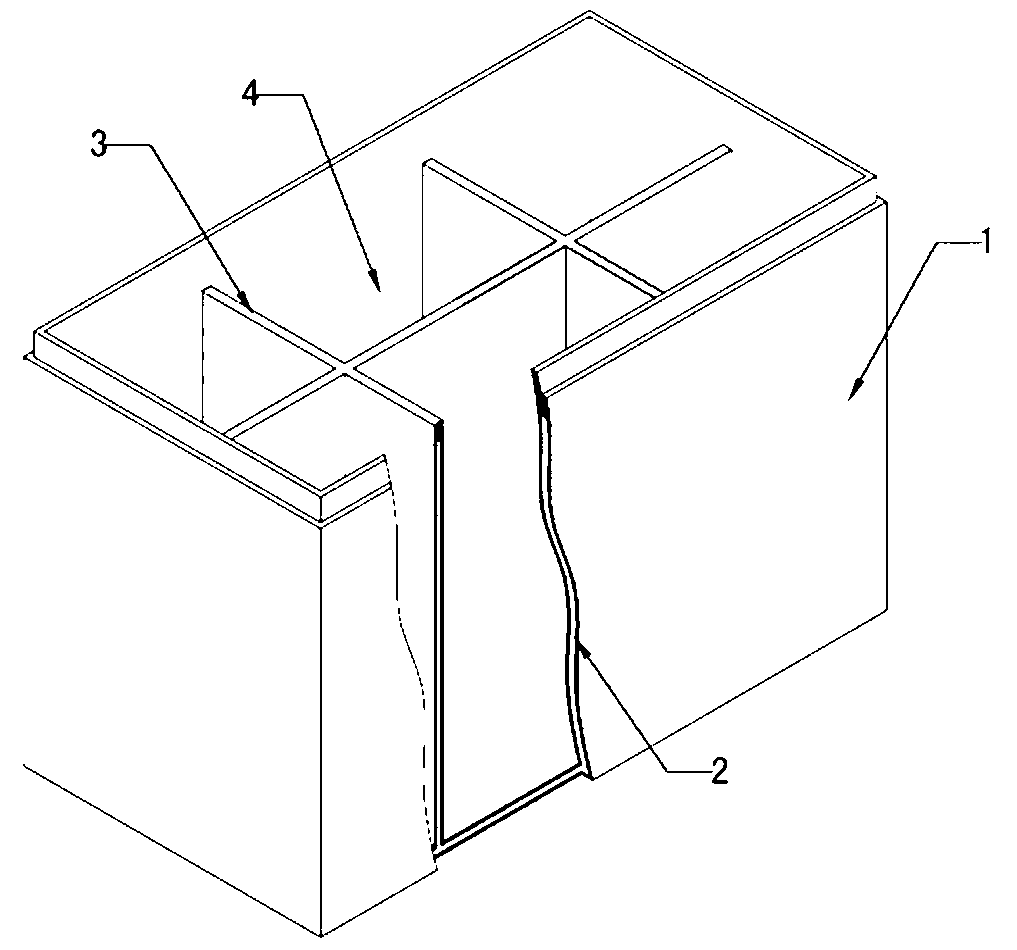

[0012] Such as figure 1 The power battery is placed in the battery tank 4 separated by the separator 3 in the box 1, the closed cavity 2 inside the side wall of the box and inside the separator is filled with a pre-selected phase change material, and the top of the box has cover. During the normal working process, the battery absorbs the heat generated by the battery through the change of the crystal phase of the phase change material; through the heat insulation characteristics of the phase change material, the battery works in a relatively constant temperature environment, and effectively realizes the effect of thermal management of the battery during the working process , in order to reduce the impact of the battery itself or the thermal changes generated by the outside world on the performance of the battery. In this example, the power battery is a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com