Low-pass filter with changeable cavity width

A technology of low-pass filter and width change, which is applied in the direction of waveguide devices, electrical components, circuits, etc. It can solve the problems of inability to fine-tune, low power capacity, and limited stop-band suppression depth, etc., and achieves convenient debugging, simple structure processing, The effect of a high passband cutoff frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

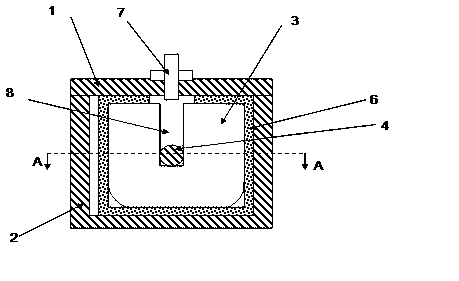

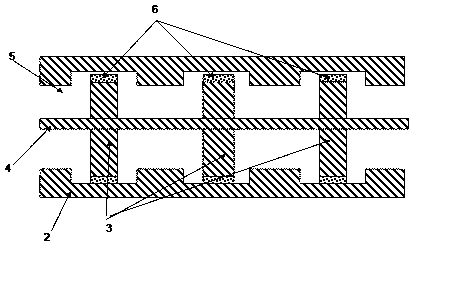

[0035] Such as figure 1 , figure 2 As shown, a low-pass filter with a variable cavity width includes a base 2 provided with a metal cavity 5, and a cover plate 1 provided on the base 2, and also includes a metal wire 4 and an insulating material 6, and is located on the metal At least three metal plates 3 in the cavity 5 are characterized in that the metal plates 3 are connected together by a metal wire 4, and the metal plates 3 are insulated from the metal cavity 5 by an insulating material 6; The cross-sectional shape is rectangular. The metal wire 4 is a columnar body, and its cross-sectional shape remains consistent along its axis; as figure 2 As shown, the cross-section of the inner wall of the metal cavity 5 is in the shape of a rectangular wave, and the two ends of the metal plate 3 are arranged in the crest of the rectangular wave.

[0036] The cross-sectional shape of the metal wire 4 is circular. The cross-sectional shape of the metal wire 4 is a rectangle. Th...

Embodiment 2

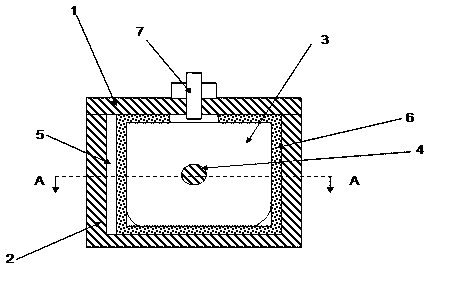

[0047] Such as image 3 As shown, the difference from Embodiment 1 is that the metal plate 3 does not have a central rectangular groove 8 on the upper surface parallel to the axial direction of the metal wire 4 , but directly opens a through hole on the metal plate 3 through which the metal wire 4 can pass. The tuning screw 7 is located directly above the metal plate 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com