Electric auxiliary bulging device for special-shaped parts

An electric-assisted, special-shaped parts technology, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult-to-deform stretched plates, difficult to form, residual stress, etc., achieve high forming efficiency, uniform temperature distribution, and solve hard to deform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

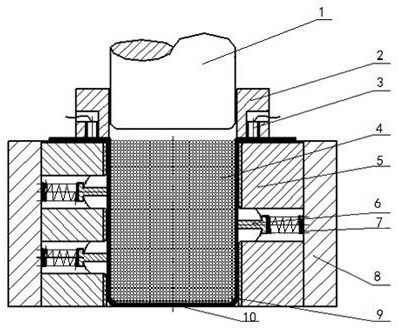

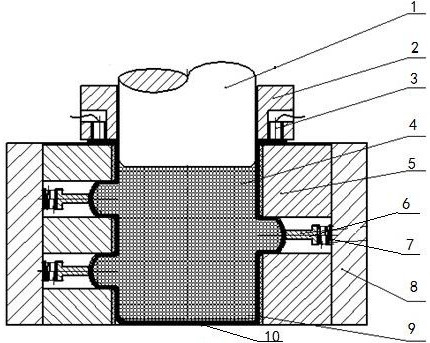

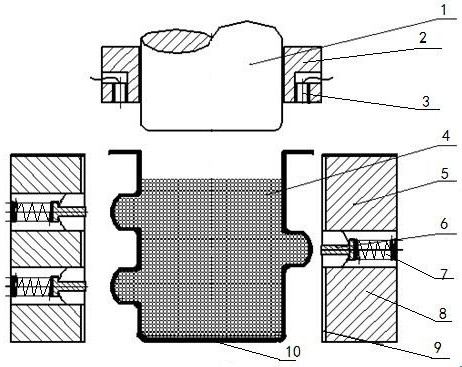

[0017] An electric assisted bulging device for special-shaped parts, comprising a punch 1, a die 5, a blank holder 2, and a sleeve 8, the die 5 is set in the sleeve 8, and the blank holder 2 is set on the upper end of the die 5 Used to press the outer edge of the cylindrical sheet 10 arranged in the die 5, the punch 1 can be lifted up and down above the center of the die 5, and the punch 1 can be seamlessly embedded in the blank holder 2; An electrode a3 is arranged inside the blank holder 2, the lower end of the electrode a3 is in contact with the outer edge of the cylindrical sheet 10, and the other end is connected to the positive pole of the power supply, and an insulating sleeve is arranged on the periphery of the electrode a3 to prevent electric leakage during bulging; A mixture of particles and viscous fluid 4 is placed in the shaped sheet 10; the two sides of the side wall of the die 5 are drilled at different heights in the radial direction and the electrode b6 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com