Control method for synchronous casting and cutting of three-phase capacitive load in three-phase circuit

A three-phase compatible, three-phase circuit technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation, etc., can solve problems such as thyristor breakdown and thyristor bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

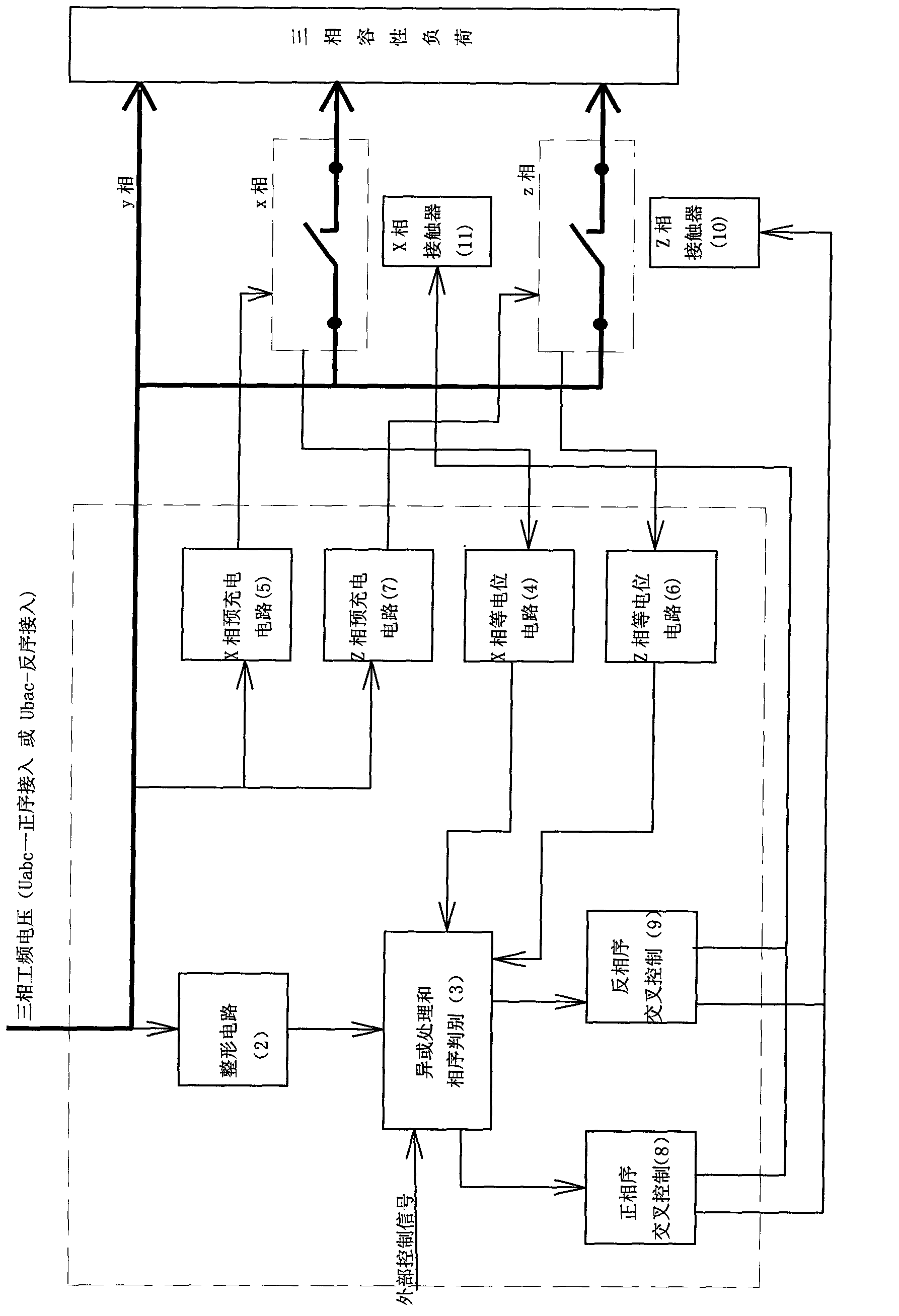

[0033] Such as figure 1 As shown, this embodiment includes the following steps:

[0034] (1) Internally define the three-phase phase sequence connected to the three-phase power supply: the three phases of the three-phase power supply are internally defined as X phase, Y phase and Z phase, and the three-phase power frequency voltage is U x , U y , U z , this definition has nothing to do with the actual phase sequence of the connected three-phase power supply, and it is assumed that the Y-phase power frequency voltage Uy lags the X-phase power frequency voltage Ux phase Z phase power frequency voltage U z Leading X-phase power frequency voltage U x phase

[0035] Phase Y is directly connected to any phase of the three-phase compatible load, and phase X and phase Z are connected to any other two phases of the three-phase compatible load through a contactor.

[0036] (2) Precharge the three-phase capacitive load: at the beginning of the initial operation of the three-phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com