Riveting device of brush box

A technology of riveting device and brush box, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of low production efficiency, low production efficiency, cumbersome processing methods, etc., and achieve accurate positioning, reasonable mechanical structure, The effect of riveting convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

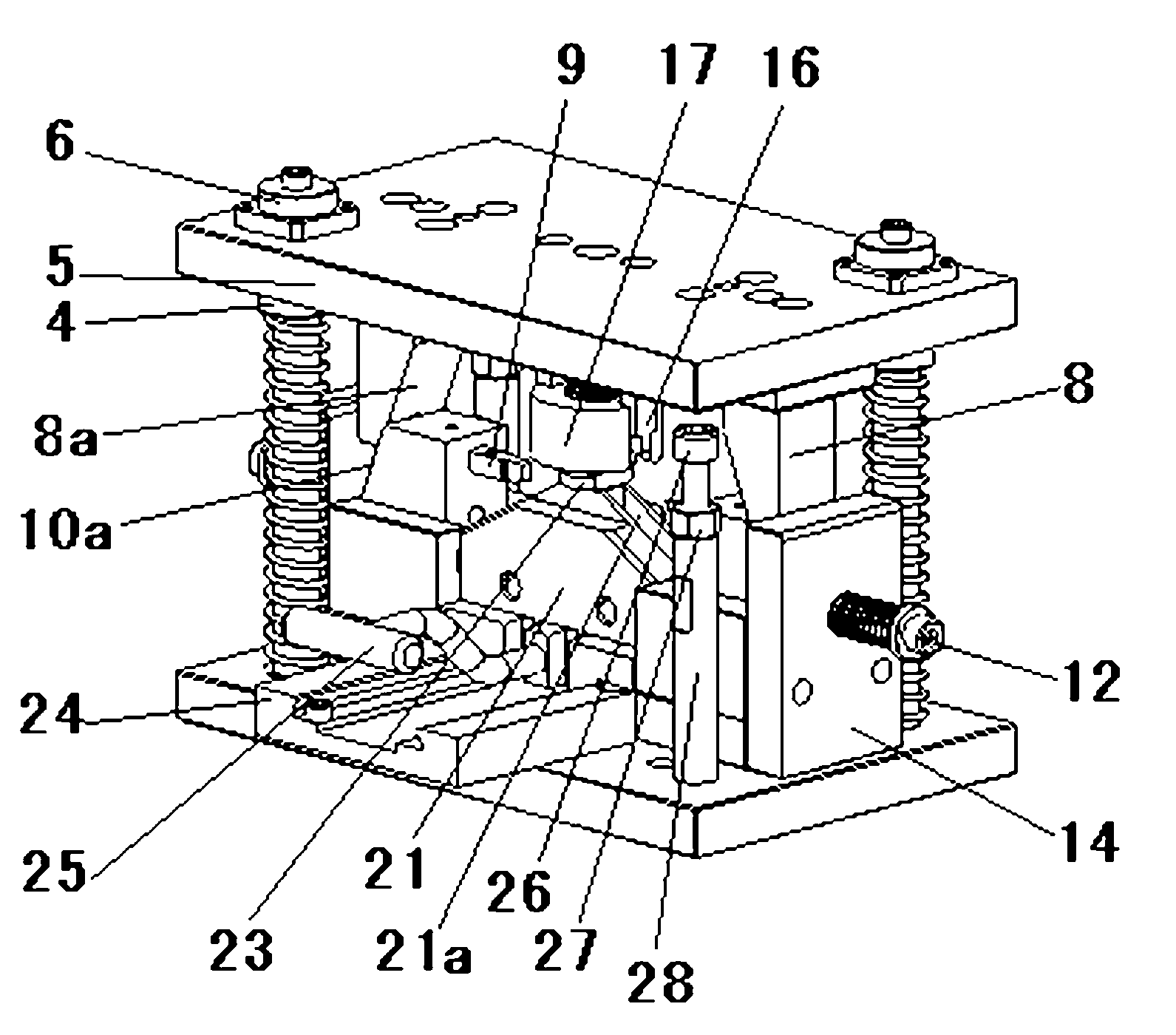

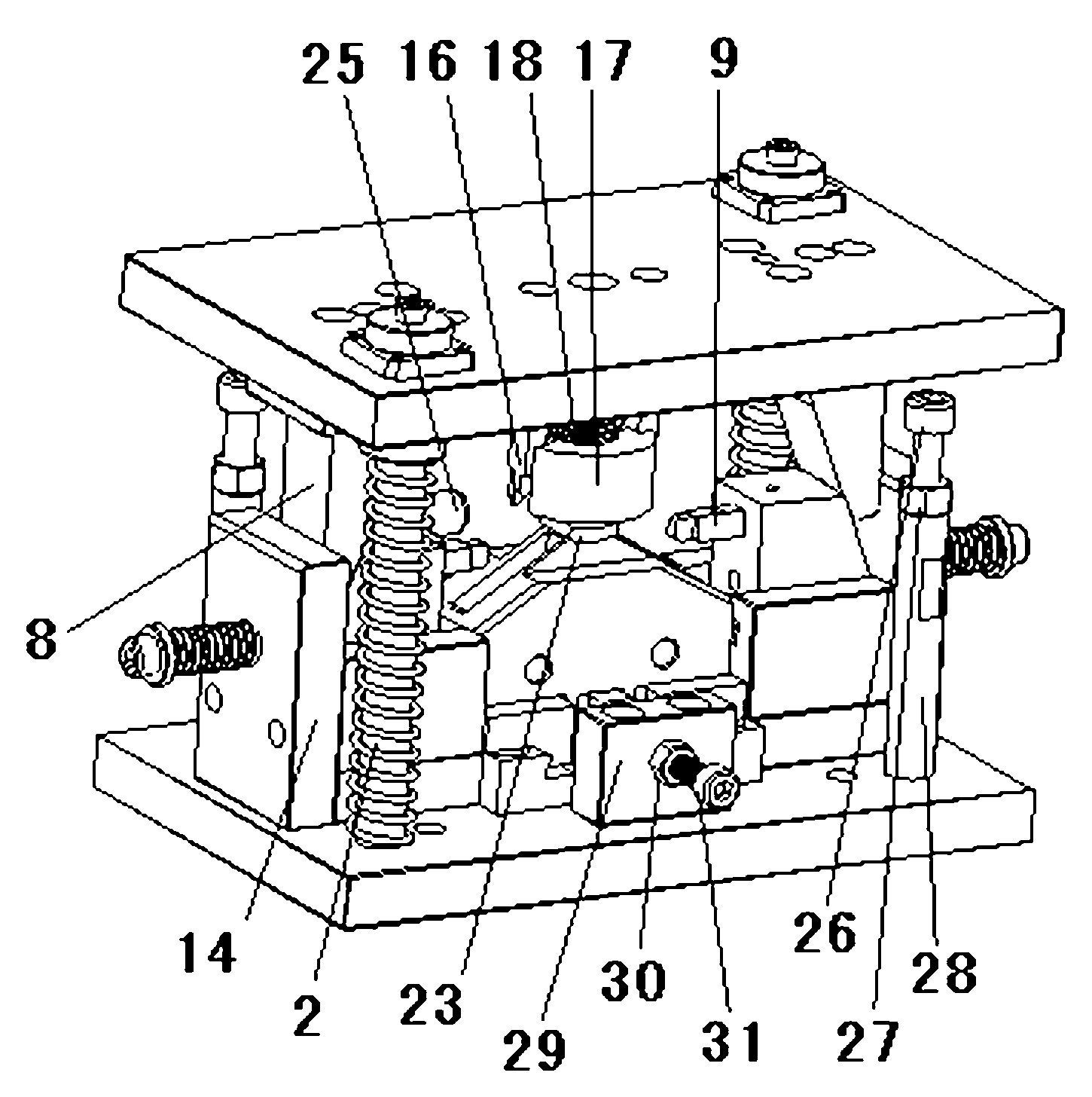

[0034] A specific embodiment of a brush box riveting device of the present invention will be further explained below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

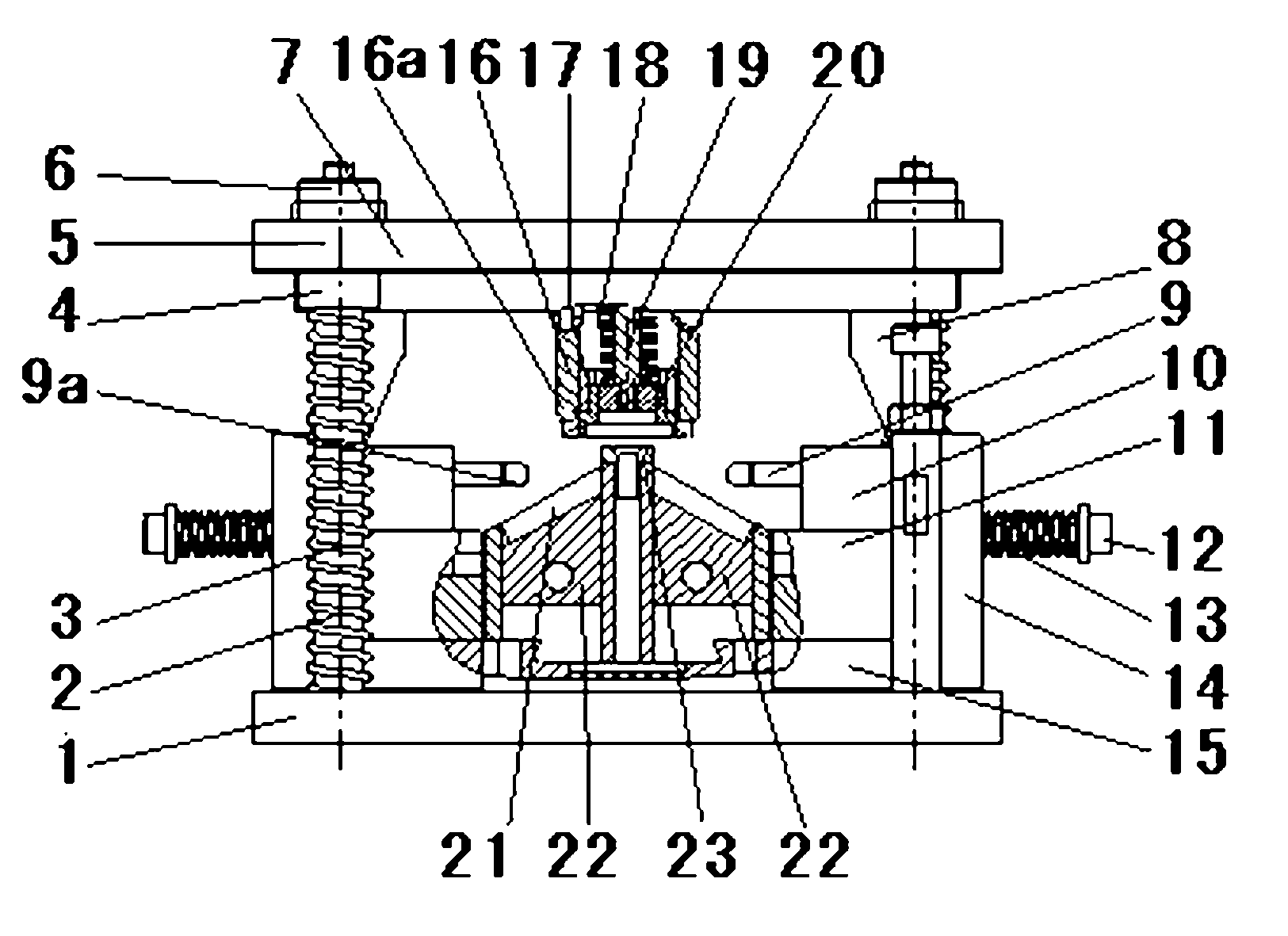

[0035] see figure 1 . A riveting device for a brush box, comprising a bottom plate 1, a top plate 5, a guide device, a horizontal riveting device, a vertical riveting device, a feeding device, an adjustable height limiting device, an adjustable feeding position limiting device and a supporting core block 34 (this Since the invention involves many components, it will be described with a large block structure first).

[0036] (see figure 1 and figure 2 ) The guide device includes a guide post 2 , a large return spring 3 , a linear bearing 4 , a limit block 6 and a fixing plate 7 . The guide post 2 is fixedly connected with the bottom plate 1 by an interference fit, the large return spring 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com