Method and device for separating out contaminants from a pneumatic fibre stream

A separation and fiber technology, applied in the direction of separating solids from solids with airflow, solid separation, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

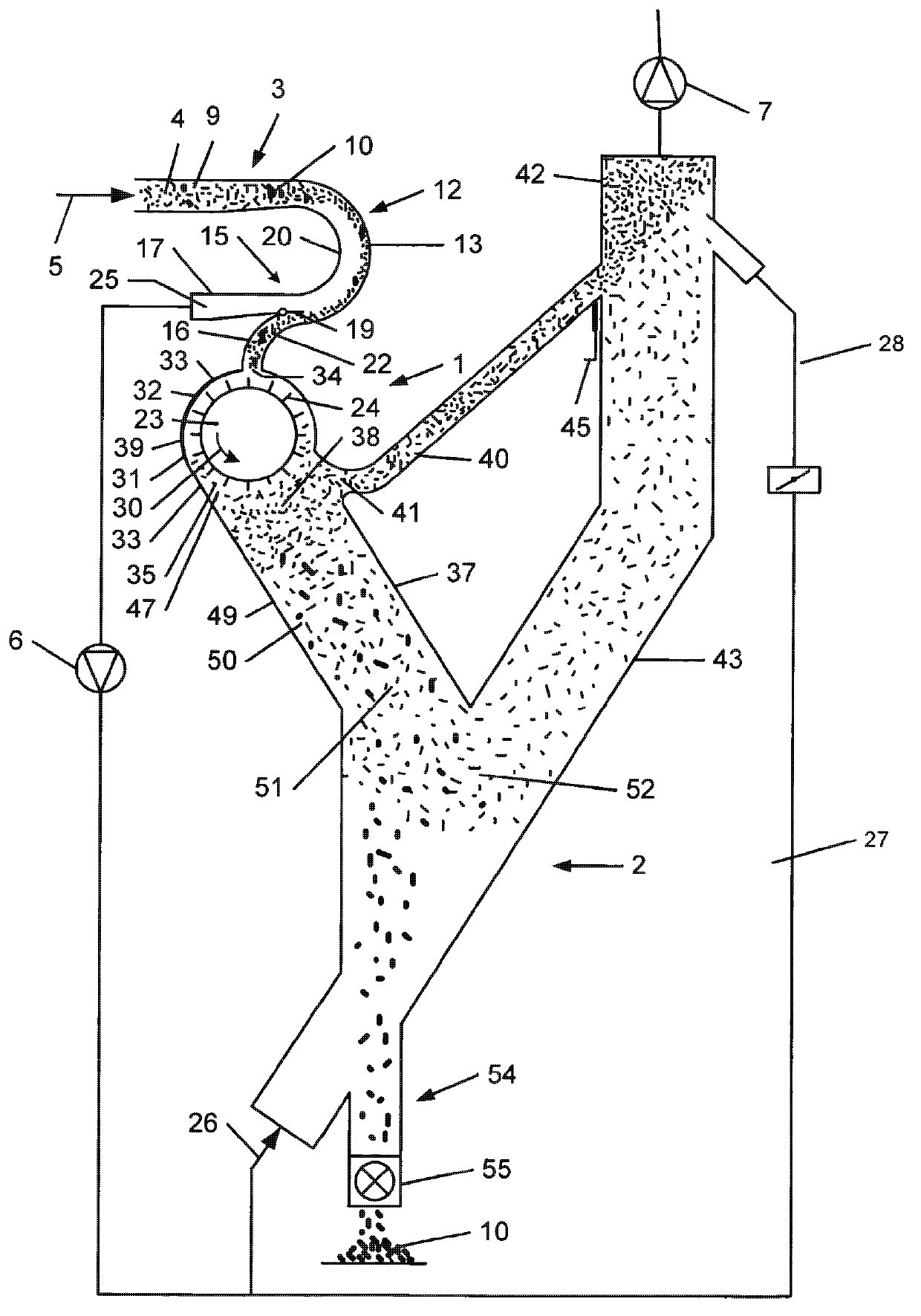

[0033] according to figure 1 is a device for separating pollutants in the form of coarse material 10 from a fiber gas stream used for the production of fibreboard. The plant consists of a pretreatment unit 1 and an air separator unit 2 . The device comprises a transport line section which guides the fiber gas flow 4 in the direction of the arrow 5 . Two fans 6 and 7 are connected to the transport line and create a negative pressure inside said transport line.

[0034] The fiber stream 4 is sucked by a device (not shown), which may be a dry fiber gluing device. Contaminants are also present in the form of relatively heavy particles between the fibers 9 representing normal material, these particles will hereinafter be referred to as coarse material 10 . The transport line section 3 is depicted as a bend 12 . This bend 12 is arranged in such a way that under the action of the centrifugal force acting on the bend 12, the fiber stream 4 will be placed on the outer area or outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com