Spun yarn winding device and spun yarn winding facility

一种卷绕装置、卷绕筒管的技术,应用在运输和包装、薄料处理、运送细丝状材料等方向,能够解决不能纺纱卷绕装置纵向尺寸抑制小、纺纱卷绕装置作业性低下、不能够有效地利用空间等问题,达到简单可靠性、结构紧凑、提高作业性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

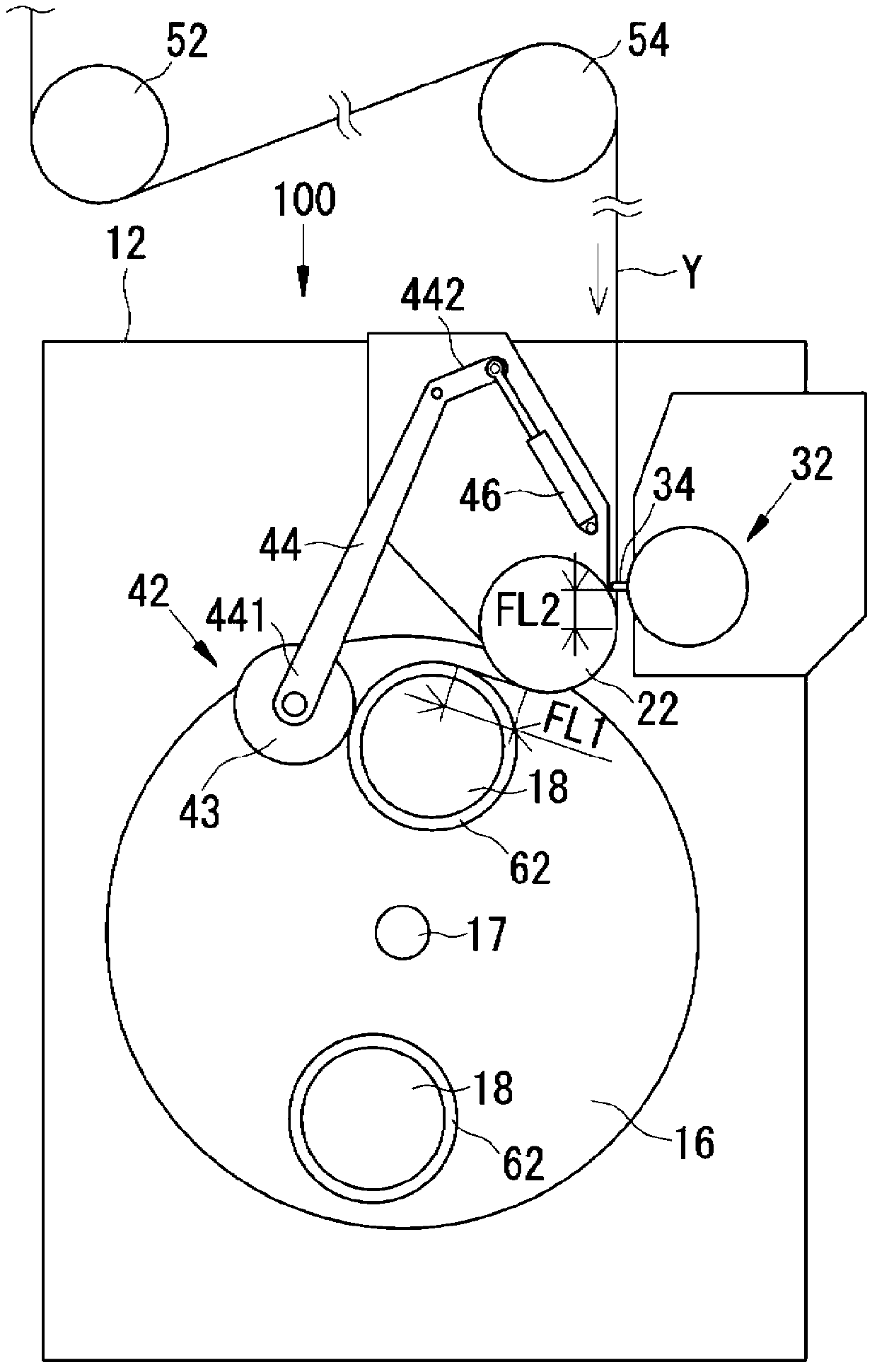

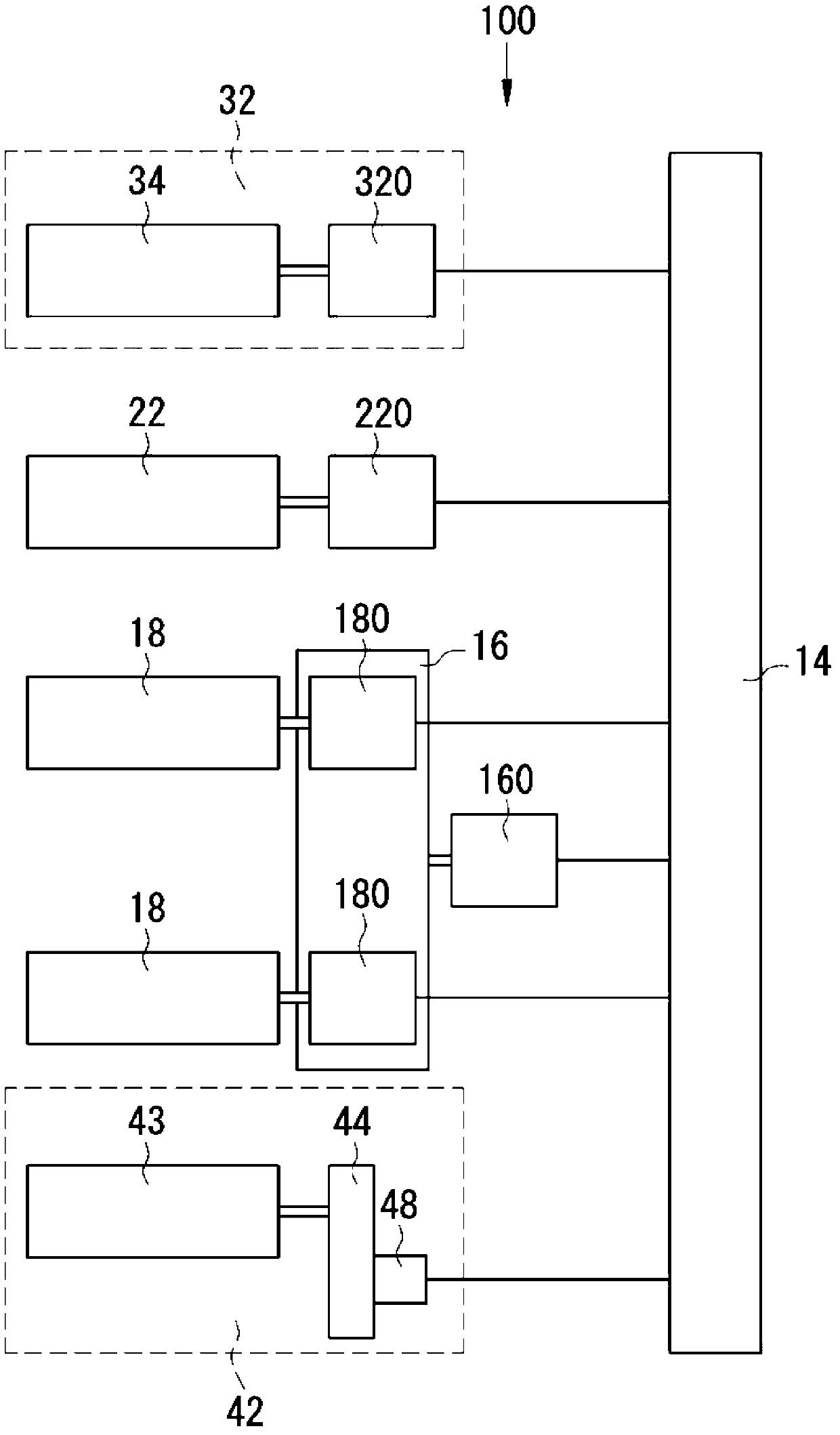

[0039] use Figure 1 to Figure 4 The spinning and winding device 100 of Embodiment 1 of the present invention will be described.

[0040] The spinning and winding device 100 of this embodiment is as figure 1 Shown is a device that winds the yarn Y onto a winding tube 62 to form a package 64 while traversing the yarn Y with the traverse device 32. The yarn Y is spun by an upper spinning device (not shown), and is fed to the spinning winding device 100 through rollers 52, 54 and the like. The running direction of the yarn Y is the direction from the upper spinning device toward the winding tube 62 as shown by the arrow.

[0041] Hereinafter, the yarn Y will be described as an elastic yarn, but the spinning winding device 100 can also wind yarns other than the elastic yarn. figure 1 Although the illustrated spinning winding device 100 is one unit, a plurality of such spinning winding devices 100 are arranged to constitute a spinning winding device.

[0042] In addition, the winding tub...

Embodiment 2

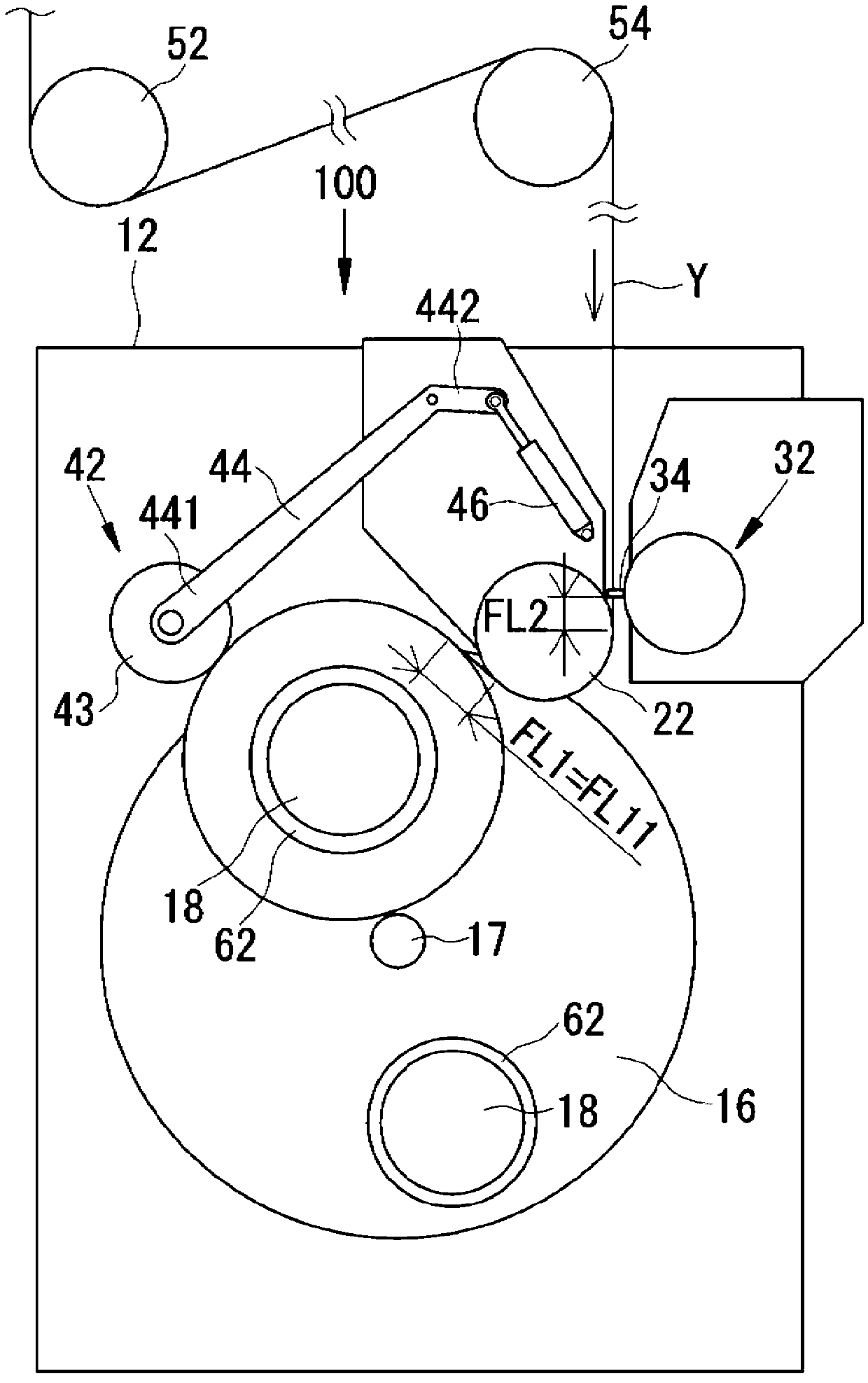

[0062] Then use Figure 5 to Figure 7 The spinning and winding device 100 of Embodiment 2 of the present invention will be described. The second embodiment is very different from the first embodiment in that a flange suppression mechanism and a loosening mechanism are incorporated in the spinning winding device 100 of the first embodiment. The detailed description of the same parts as in the first embodiment is omitted.

[0063] First, the flange suppression mechanism in the spinning winding device 100 of the present embodiment will be described. In the case of an elastic yarn, if the winding speed of the yarn increases, the yarn path tends to become unstable. Therefore, the elastic yarn is subjected to high tension and is wound on the winding bobbin in an extended state. If the yarn is wound onto the winding bobbin in an extended state, the tensile stress of the yarn is accumulated in the inner layer of the package. The tightening force of the yarn caused by the accumulation ...

Embodiment 3

[0078] Then use Figure 8 The spinning and winding device 200 of Embodiment 3 of the present invention will be described. The spinning winding device 200 of this embodiment is configured by combining a plurality of spinning winding devices 100 described in the first embodiment into an upper layer and a lower layer. The detailed description of the spinning winding device 100 is omitted.

[0079] Such as Figure 8 As shown, the upper and lower layers of the spinning winding device 200 of the present embodiment are simultaneously provided with a spinning winding device 100 in a longitudinally disposed form. The yarn Y is spun by an upper spinning device (not shown), and is fed to each spinning winding device 100 through rollers 52, 54, 56 and the like. The yarn Y is supplied to the traverse device 32 of each spinning winding device 100 from above.

[0080] In the case of combining a plurality of spinning winding devices 100 into an upper layer and a lower layer in a vertical arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com