Root fixing backrest plastic chair

A blade connection and backrest technology, applied in chairs, other seating furniture, stools, etc., can solve problems such as bulkiness, simple design, and unsightly appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

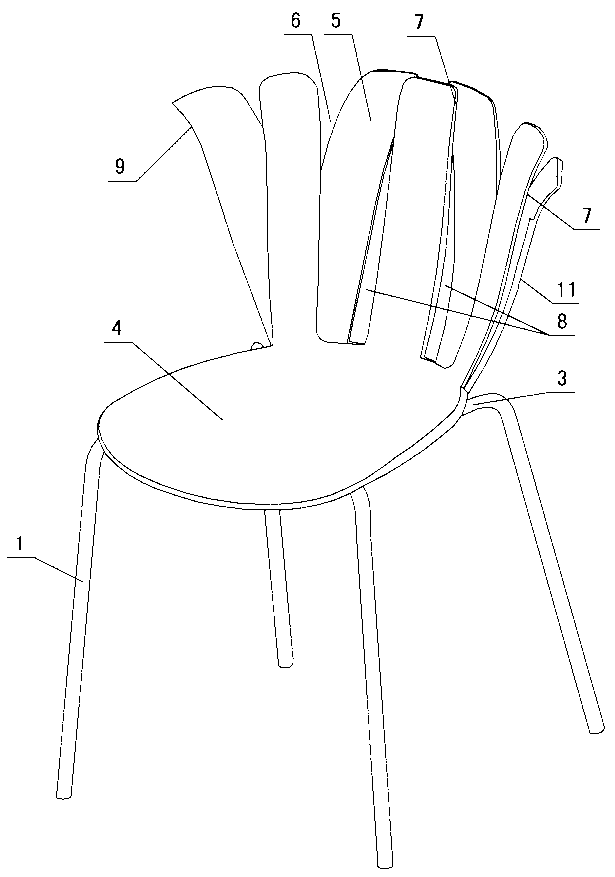

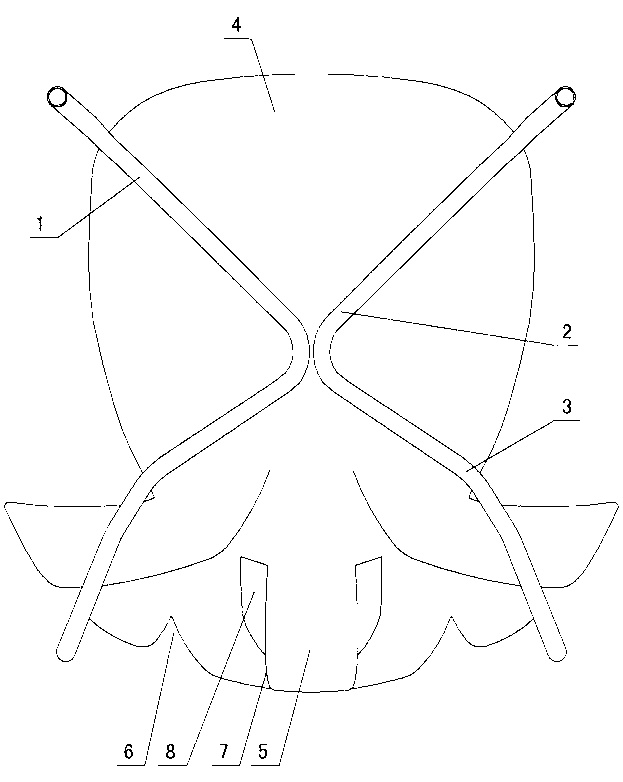

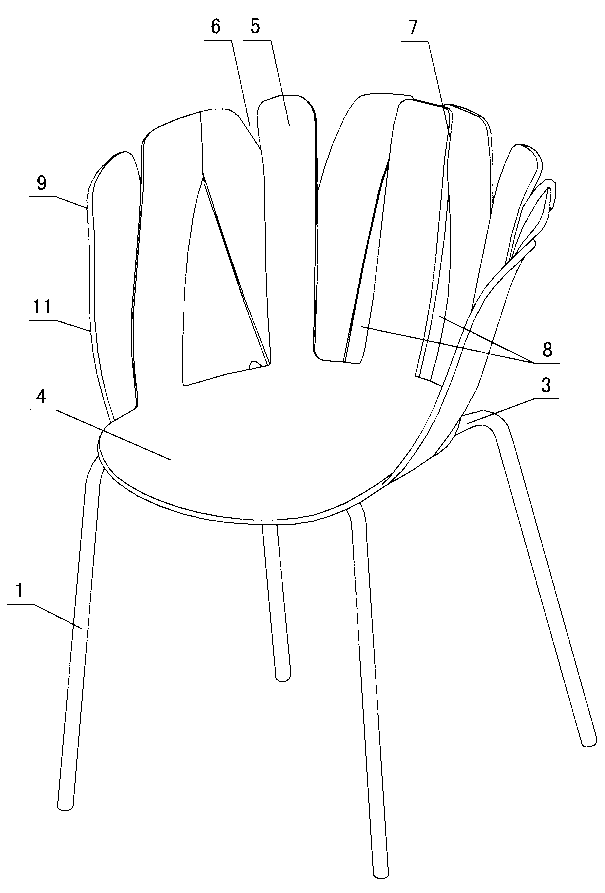

[0010] The invention relates to a blade-connected backrest plastic chair, such as figure 1 — image 3 As shown, it includes a chair foot, a seat plate and a chair back, and is characterized in that: the chair back is a sheet plate 5 extending upwards from the periphery of the seat plate 4, and there are joints 7, Slits 6 or split holes 8, the middle part of the sheet plate 5 is an outwardly inclined surface 11, and the upper part of the sheet plate 5 is an outward arcuate surface 9. The chair legs 1 are connected to the bottom surface of the seat plate 4, including the legs 1. A curved and drooping cross bar 3 is formed on the top of the support leg, and the cross bar extends toward the center to form a support frame 2 . The back of the chair is shaped like a bamboo leaf or a leaf similar to rice or wheat. The lower end of the leaf is connected to the periphery of the seat plate 4, and extends upward from the periphery of the seat plate 4 to form a sheet-like plate 5. This st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com