Large-scale steel pipe

A steel pipe and large-scale technology, applied in the field of large-scale steel pipe manufacturing, can solve the problems of low manual welding efficiency, high manufacturing cost, and long production hours, and achieve the effect of automation and mass production that are convenient for welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

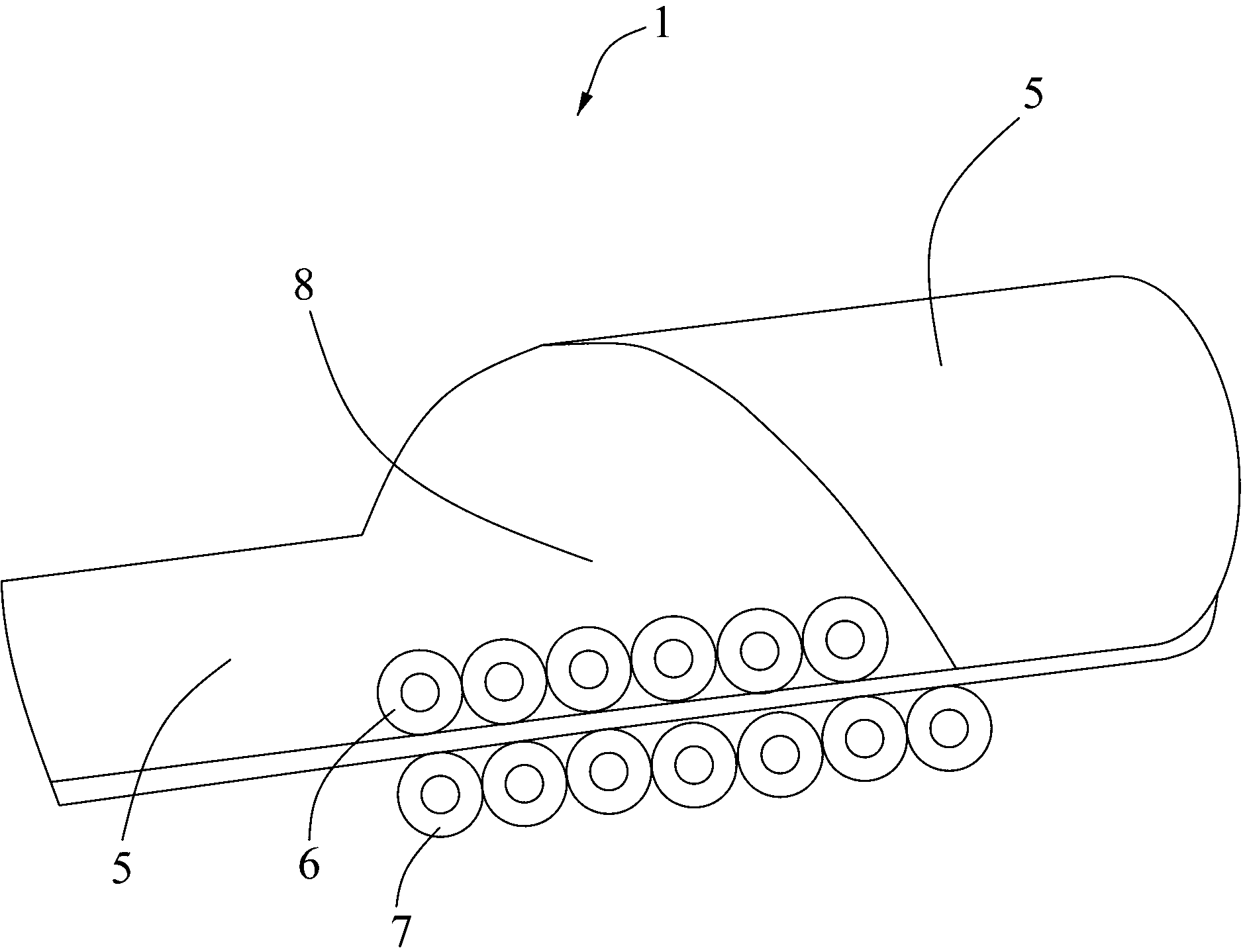

[0014] Such as figure 1 As shown, a method for manufacturing a large steel pipe includes: 1) providing a steel plate 5; 2) pulling the steel plate 5 into a welding cavity 8 with an upper welding wheel 6 and a lower welding wheel 7; 3) continuously pulling the steel plate 5 for welding Large-scale cylindrical steel pipe 1. The upper welding wheel 6 welds the steel plate 1 at the joint of the steel plate 5. The lower welding wheel 7 welds the steel plate 5 at the joint of the steel plate 5. The upper welding wheel 6 and the lower welding wheel 7 are arranged symmetrically. The upper welding wheel 6 is arranged inside the steel plate 5. The 7 lower welding wheels are arranged on the outside of the steel plate 5. The steel plate 5 is pulled by mechanical equipment.

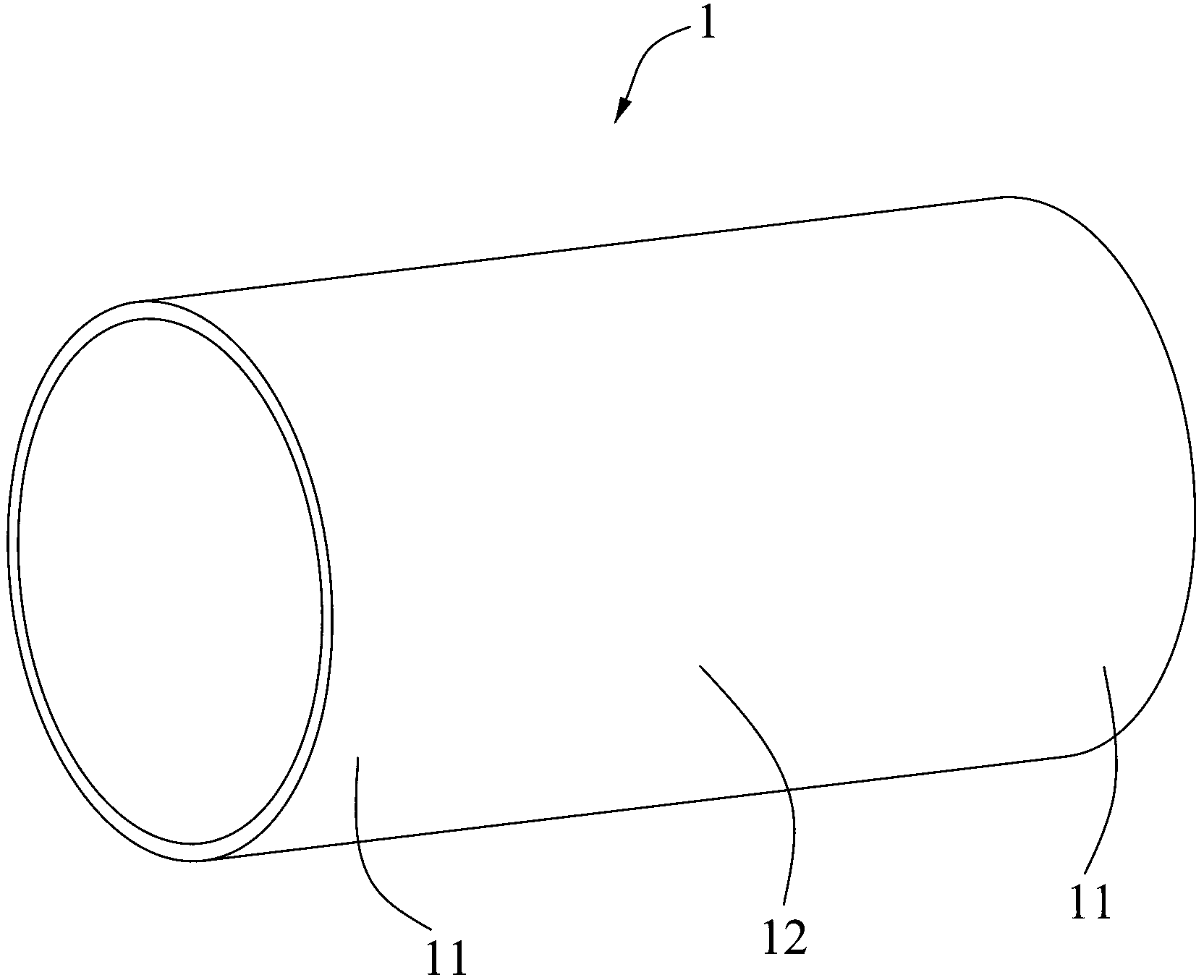

[0015] Such as figure 2 Shown as figure 1 The large-scale steel pipe 1 produced by the method of manufacturing the large-scale steel pipe shown. The large steel pipe 1 includes: a cylindrical tube, and paint 3 spra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap