Movable temperature measuring device for hot forming of sheets

A temperature measuring device and thermoforming technology, applied in the direction of measuring devices, electric devices, and thermometers using electric/magnetic elements that are directly sensitive to heat, can solve the problems of not being able to directly measure the temperature of the sheet metal, and achieve a wide range of applications , easy control, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

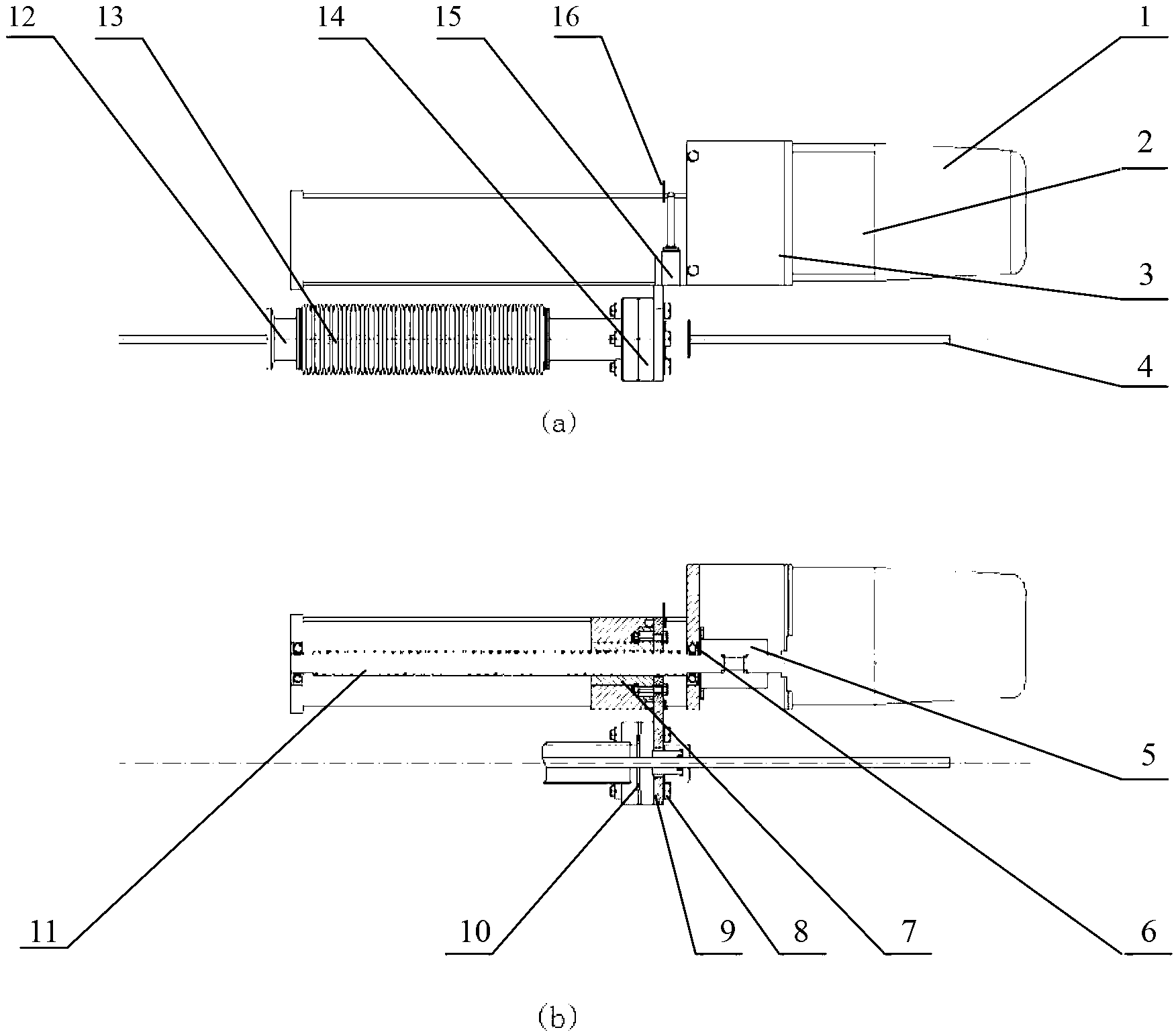

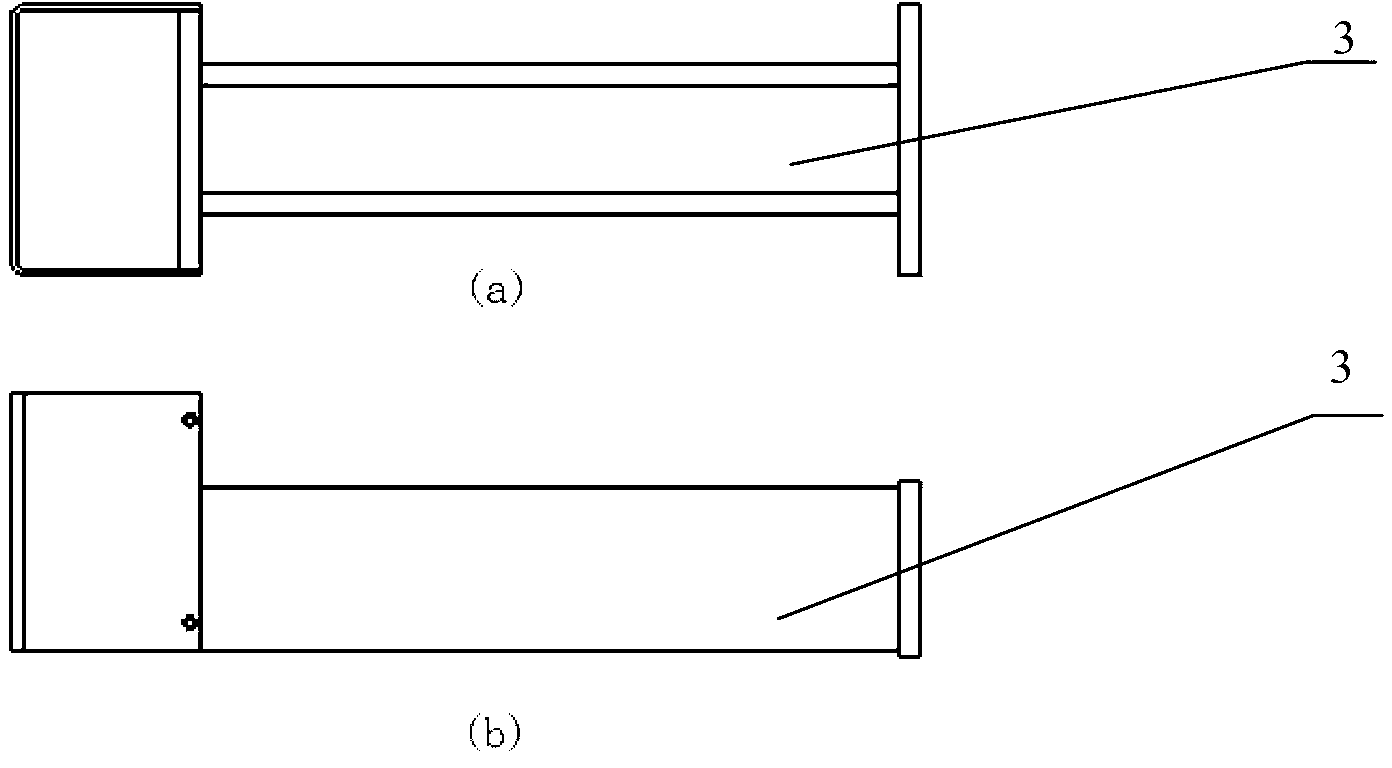

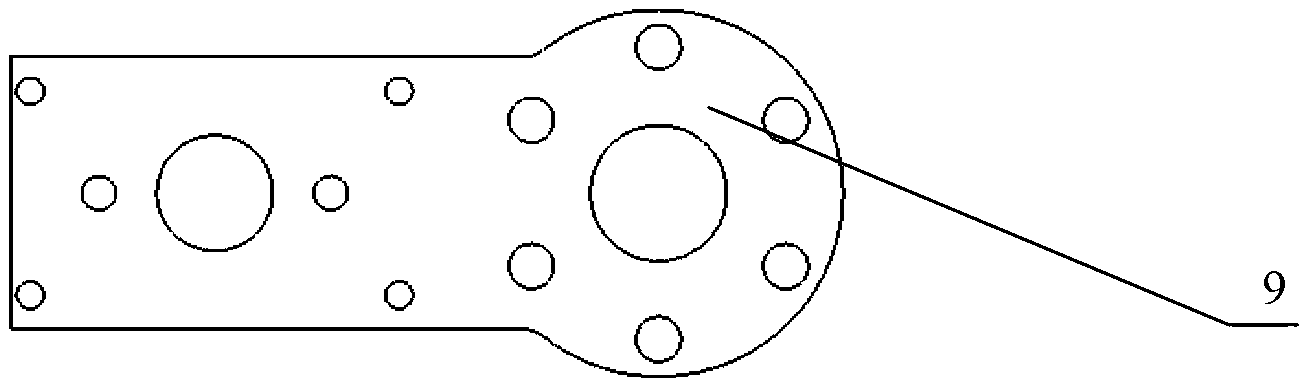

[0032] The present invention is a movable temperature measuring device for sheet metal thermoforming, and its structural schematic diagram is as follows figure 1 As shown in (a) and (b), including motor 1, reducer 2, motor bracket 3, thermocouple 4, coupling 5, bearing 6, nut 7, bolt 8, connecting plate 9, compression seal ring 10, ball Lead screw 11, quick release flange 12, bellows 13, welding high vacuum flange 14, travel switch 15, baffle 16.

[0033] Both ends of the ball screw 11 are provided with bearings, and are fixed on the motor bracket 3, the ball screw 11 is connected with the reducer 2 through the coupling 5, the nut 7 is threaded with the ball screw 11, and the connecting plate 9 is fixed on the nut 7 superior. When the motor 1 rotates, the ball screw 11 also rotates, the nut 7 moves in a straight line, and the thermocouple 4 also moves along with the nut 7 to reach the position where the temperature needs to be measured. One end of the bellows 13 is a welded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com