Vertical material feeding and discharging manipulator

A manipulator and vertical technology, applied in the direction of manipulators, program control manipulators, metal processing equipment, etc., can solve the problems that product quality cannot be effectively guaranteed, it is difficult to meet mass production, and the work intensity of operators is high. Mass production, avoiding personal safety accidents, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

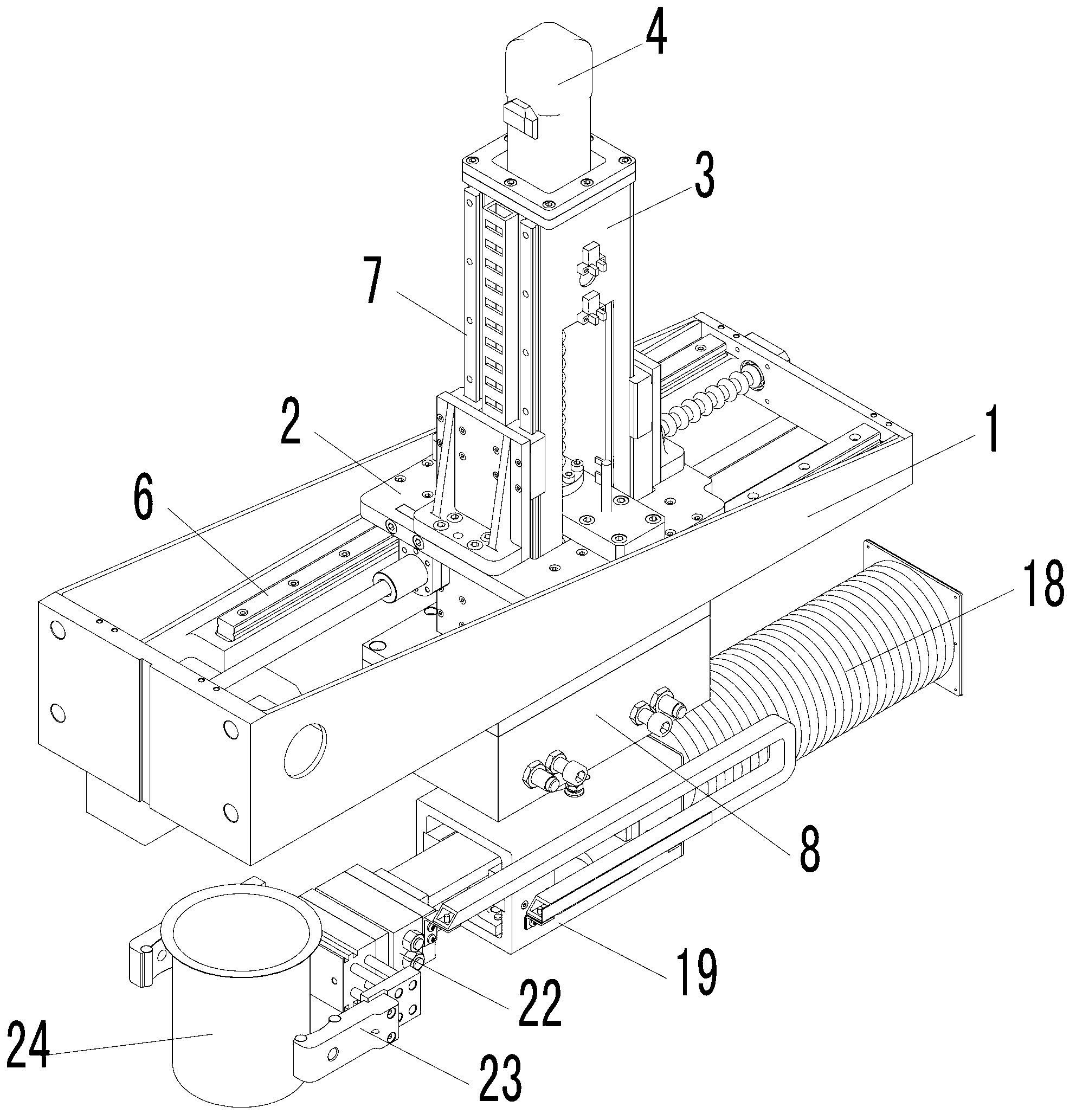

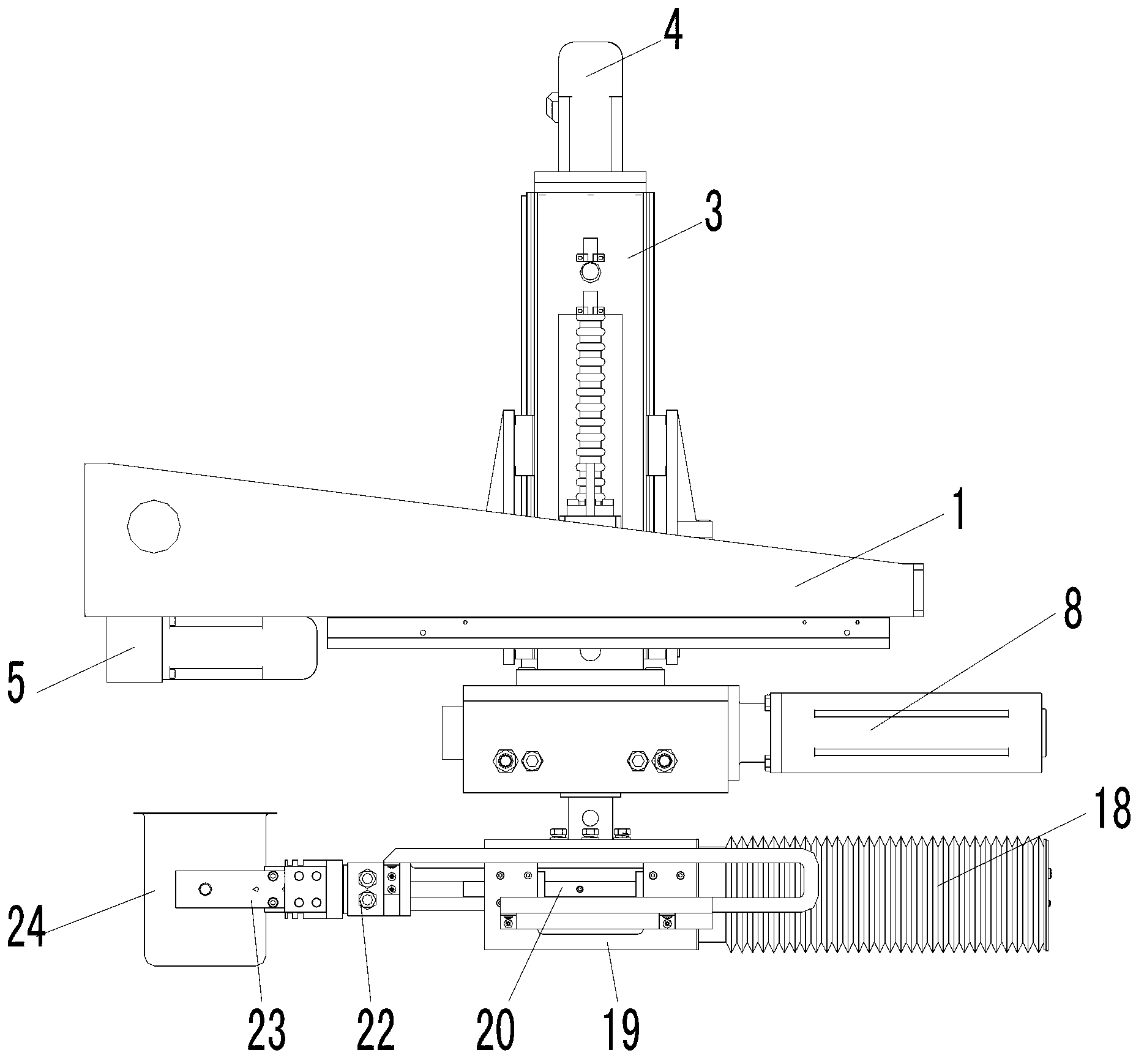

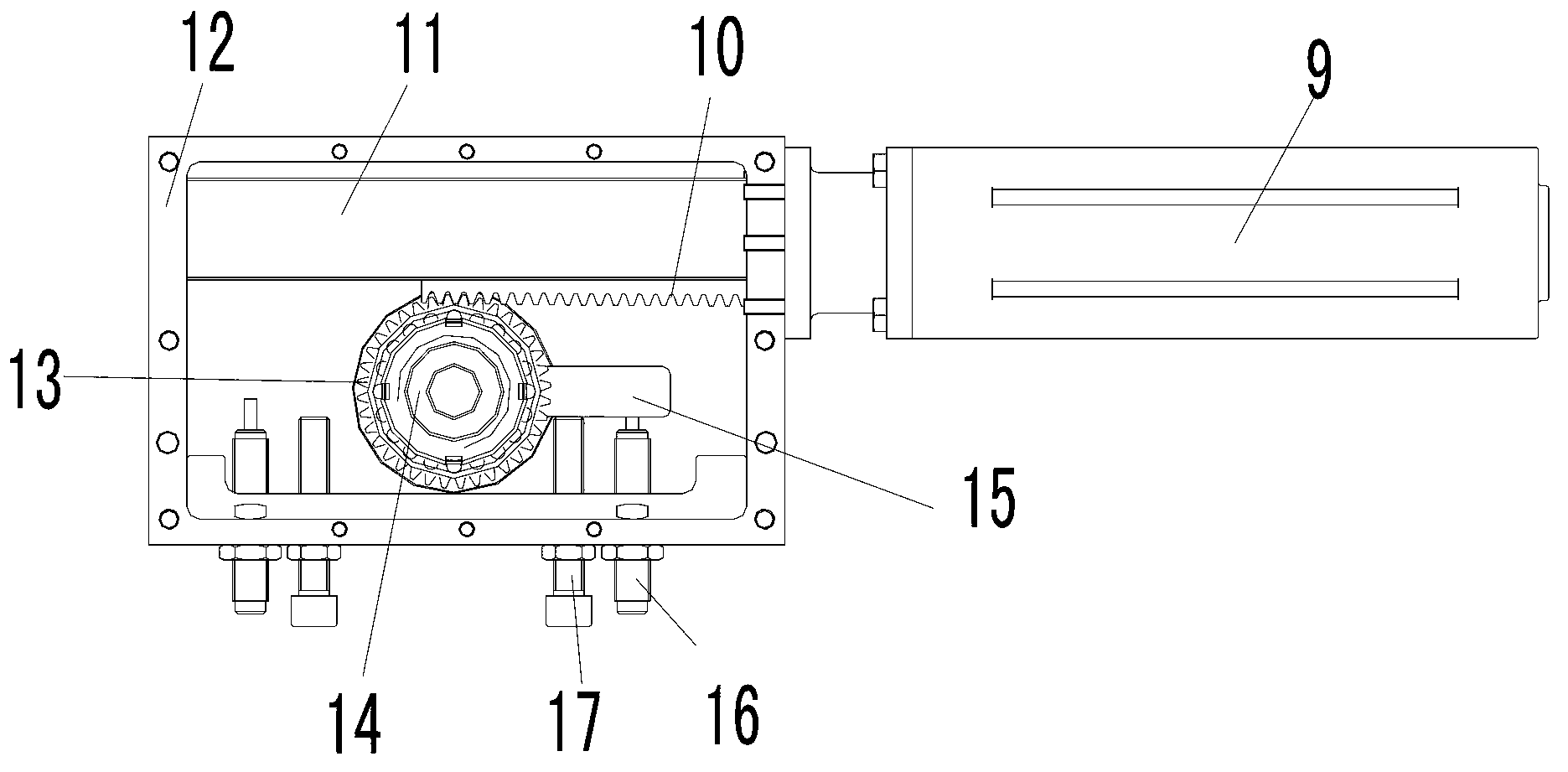

[0017] attached figure 1 , 2 , 3 is a kind of vertical loading and unloading manipulator described in the present invention, comprises frame 1, horizontal moving block 2, vertical moving column 3, vertical servo motor 3, horizontal servo motor 4, rotation control device 8, telescopic cylinder 18, manipulator Box 19, manipulator arm 21, clamping part 23; The first linear guide rail 6 is arranged on the frame 1, the horizontal moving block 2 is arranged on the first linear guide rail 6, and the frame 1 is provided with A ball screw (not shown), the ball screw passes through the horizontal moving block 2; the horizontal servo motor 5 is connected with the ball screw and can drive the ball screw to rotate; when the ball screw rotates, it drives the horizontal The moving block 2 moves along the first linear guide rail 6; the lower end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com