Transporter for plastic belts

A transportation device and plastic belt technology, which is applied in transportation and packaging, multi-axis trolleys, trolleys, etc., can solve the problems of easy damage of the outer plastic belt, personal injury, high labor intensity, etc., and achieve simple structure, reduce impact, and reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

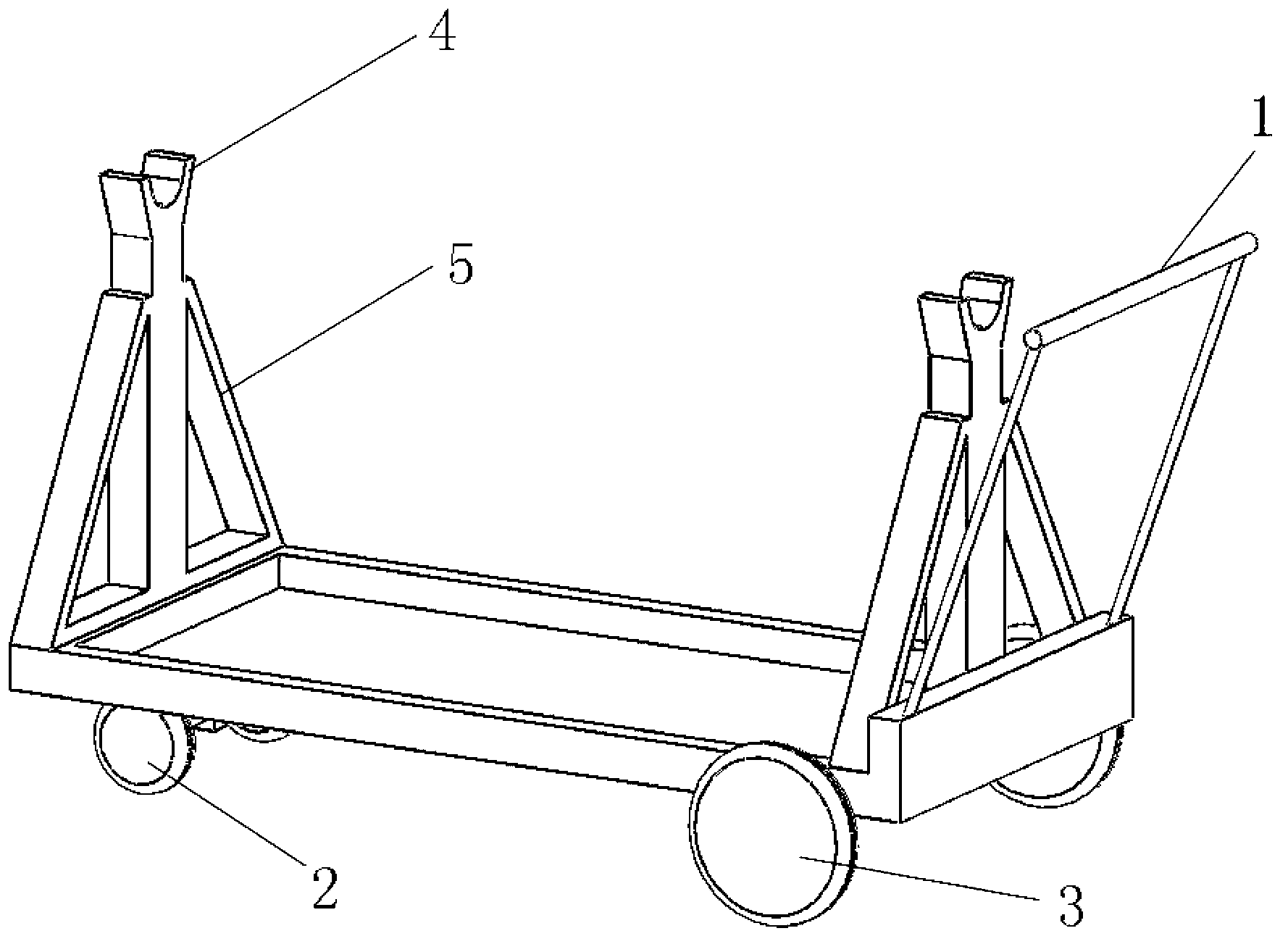

[0019] Such as figure 1 Said, a plastic belt transportation device, comprising a vehicle frame, the front and rear ends of the vehicle frame are provided with vertical frames. One end of the vehicle frame is provided with a push handle 1, and a plurality of wheels are provided on the lower end surface of the vehicle frame. The vehicle frame is a steel pipe made of metal material with a thickness of 0.5-2.5cm.

[0020] In this embodiment, the frame body includes a support frame 4 with a fork at the upper end. A reinforcement frame 5 is arranged on the support frame 4 . Four universal wheels are arranged on the lower end surface of the vehicle frame. In another case, two universal wheels 2 are arranged on the lower end surface of the front part of the vehicle frame, and two fixed wheels 3 are arranged on the lower end surface of the rear part of the vehicle frame. The universal wheel is provided with a braking device.

[0021] In this embodiment, the support frame 4 is an i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com