Winch integrated monitoring device

A comprehensive monitoring and winch technology, applied in hoisting devices, clockwork mechanisms, etc., can solve the problems of high cost and unsuitable mining winch monitoring, achieve simple structure, avoid blindness, and improve work quality and efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

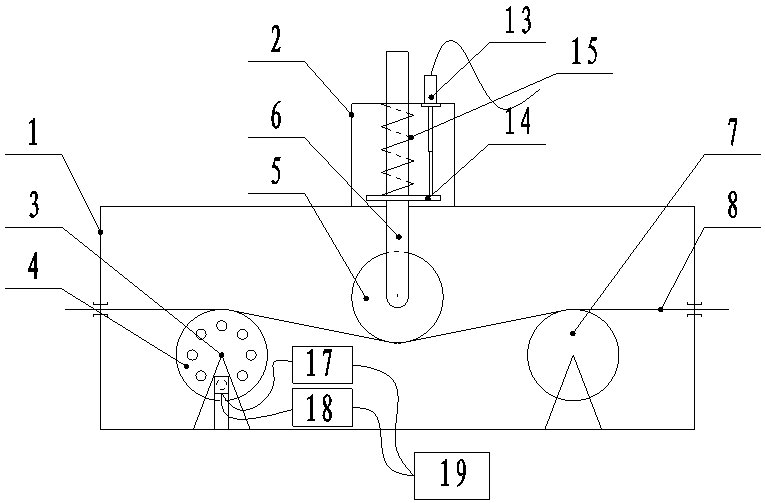

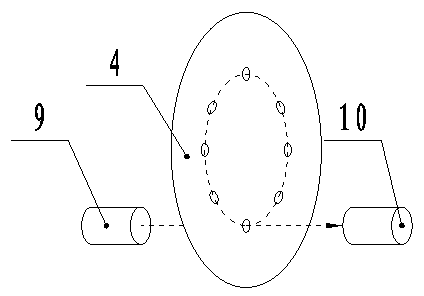

[0021] Such as figure 1 , Figure 5 As shown, the winch comprehensive monitoring device includes a housing 1, a sensor housing 2, a counting device 3, a force measuring wheel 5, a force measuring rod 6, an auxiliary wheel 7, a linear displacement sensor 13, a single-chip computer for traction calculation, a single-chip computer for length calculation 17, and a speed calculation Single-chip microcomputer 18 and display 19, described counting device 3 and auxiliary wheel 7 are installed inside the shell and the counting wheel 4 in the counting device 3 is parallel to the axis of auxiliary wheel 7, and steel wire rope 8 runs through the shell, and steel wire rope 8 and counting wheel 4 and auxiliary The top of the wheel 7 is in contact, the force measuring wheel 5 is located between the counting wheel 4 and the auxiliary wheel 7, its bottom is in contact with the wire rope 8 and presses the wire rope 8 downward, and the sensor housing 2 is fixed on the top of the housing 1 and in...

Embodiment 2

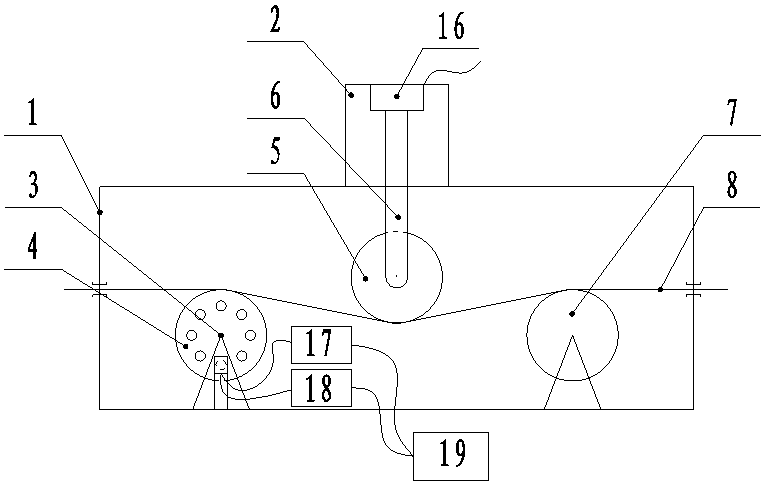

[0030] Such as figure 2 , Figure 5 As shown, the winch comprehensive monitoring device includes a housing 1, a sensor housing 2, a counting device 3, a force measuring wheel 5, a force measuring rod 6, an auxiliary wheel 7, a linear displacement sensor 13, a single-chip computer for traction calculation, a single-chip computer for length calculation 17, and a speed calculation Single-chip microcomputer 18 and display 19, described counting device 3 and auxiliary wheel 7 are installed inside the shell and the counting wheel 4 in the counting device 3 is parallel to the axis of auxiliary wheel 7, and steel wire rope 8 runs through the shell, and steel wire rope 8 and counting wheel 4 and auxiliary The top of the wheel 7 is in contact, the force measuring wheel 5 is located between the counting wheel 4 and the auxiliary wheel 7, its bottom is in contact with the wire rope 8 and presses the wire rope 8 downward, and the sensor housing 2 is fixed on the top of the housing 1 and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com