Oxygen pressure adjustment apparatus and adjustment method for electric furnace

A technology of adjustment device and adjustment method, applied in furnace control device, electric furnace, furnace and other directions, can solve the problems of valve oscillation, high pressure, and inability to drop the working pressure, and achieve the effect of small modification and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention aims to solve the problem of overcoming the influence of huge changes in production gas and stabilizing the gas delivery pressure in the occasion where a gas buffer tank cannot be installed. Utilize two membrane regulating valves, one large and one small, and set several working points according to the set value of the flow rate, and automatically switch between the two valves. The large valve and the small valve cooperate to adjust each other, which can ensure the pipeline gas under the large and small flow rate. The pressure remains stable, meets the requirements of the process, and saves equipment investment.

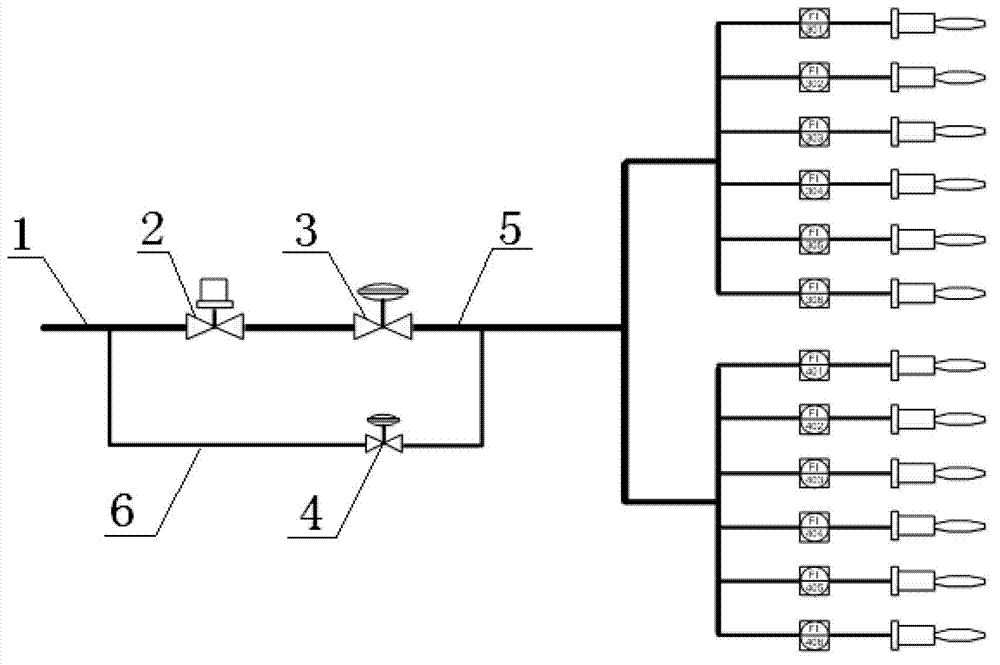

[0016] specific as figure 1 As shown, the present invention is that the oxygen main pipe 1 is connected to the burner and the oxygen lance through the main pipe 5 and the branch road 6 respectively; There is a branch regulating valve 4, so that the pressure adjustment of the oxygen main pipe can be realized through the cooperation of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com