Laminating 3D (three-dimensional) sound absorber and preparation method thereof

A 3D and film-coated technology, applied in the field of film-coated 3D sound-absorbing body and its preparation, can solve the problems of not obvious low-frequency sound-absorbing effect, monotonous appearance effect of sound-absorbing body, complicated forming structure of sound-absorbing body, etc., and achieve sound-absorbing effect Good, easy to install, sound absorption effect improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

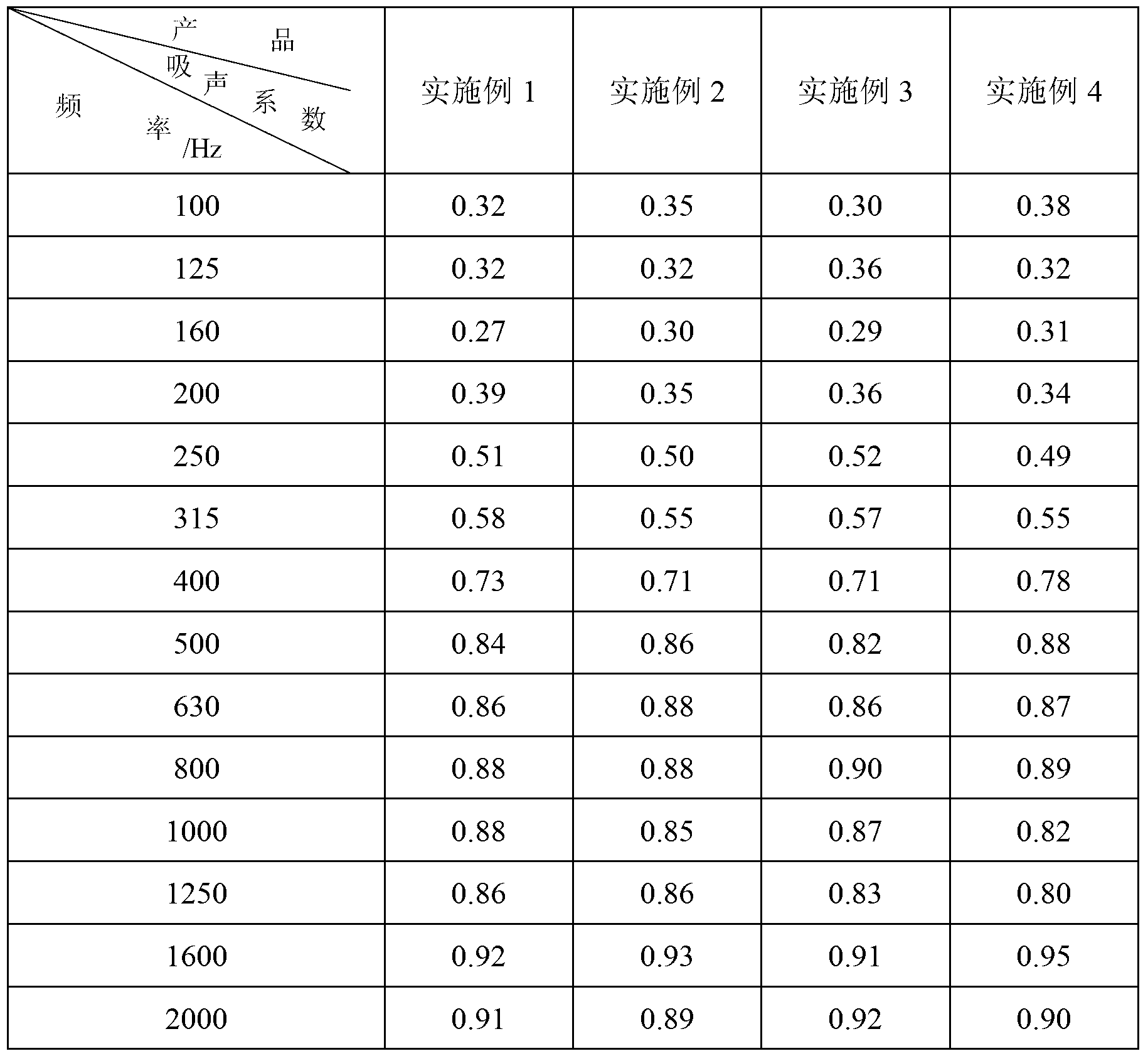

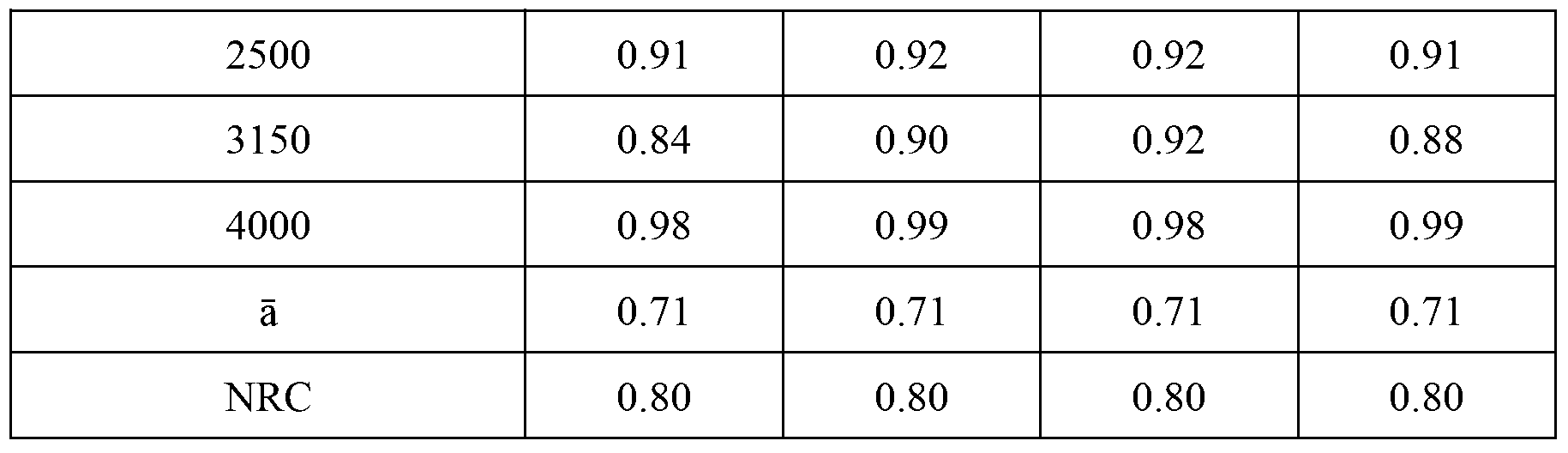

Embodiment 1

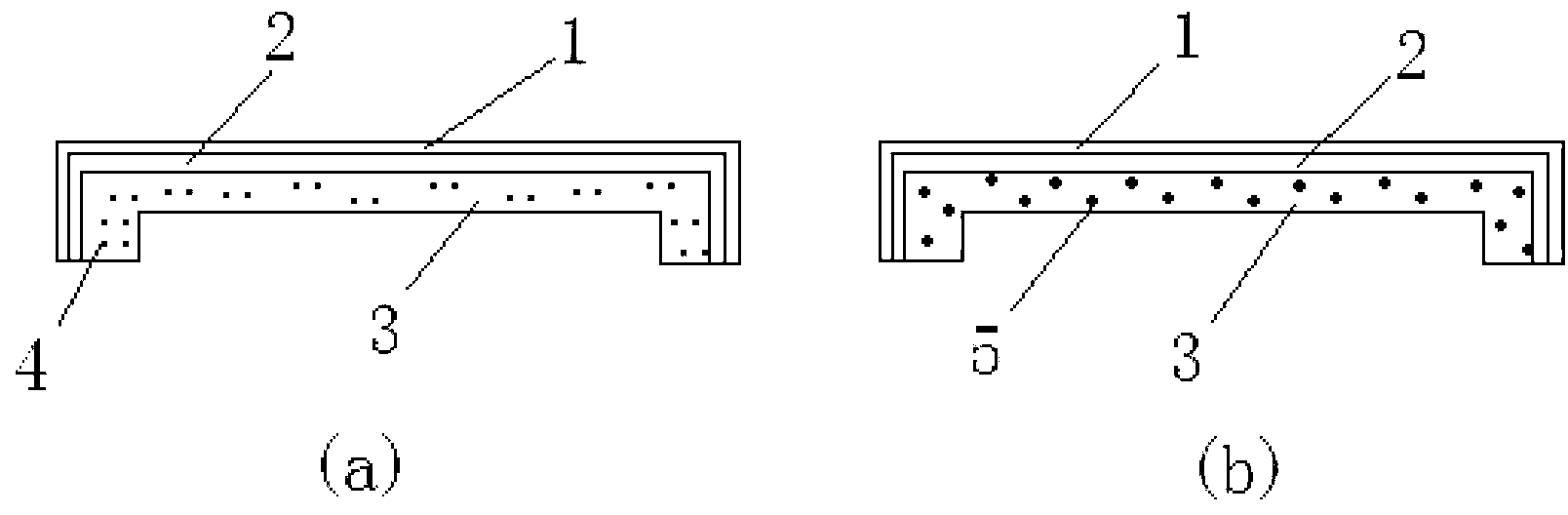

[0034] like figure 1 The shown coated 3D sound absorbing body includes a covering layer, a first polyester staple fiber mesh layer and a fiber cotton layer that are sequentially compounded; the fiber cotton layer includes a first polyester staple fiber and uniformly distributed in the first polyester staple fiber. The quality of the first polyester staple fiber mesh layer is 2% of the mass of the fiber cotton layer; the melting point of the first polyester staple fiber is 180 ° C; the melting point of the second polyester staple fiber is 258°C.

[0035] The ratio of the second polyester staple fibers to the first polyester staple fibers in the fiber cotton layer is 1:1.

[0036] There are needle punch holes evenly distributed on the surface of the fiber cotton layer, the diameter of the needle punch hole is 1.8mm, the depth of the needle punch is three quarters of the thickness of the fiber cotton layer, and the needle punch density is 1.2 needles / cm 2 .

[0037] The thickn...

Embodiment 2

[0050] The film-coated 3D sound absorbing body includes a covering layer, a first polyester short fiber mesh layer and a fiber cotton layer that are sequentially compounded; the fiber cotton layer includes a first polyester short fiber and a first polyester short fiber uniformly distributed in the first polyester short fiber. Dipolyester staple fibers; the mass of the first polyester staple fiber web layer is 6% of the mass of the fiber cotton layer; the melting point of the first polyester staple fiber is 188°C; the melting point of the second polyester staple fiber is 263°C .

[0051] The ratio of the second polyester staple fibers to the first polyester staple fibers in the fiber cotton layer is 1:2.

[0052]There are acupuncture holes evenly distributed on the surface of the fiber cotton layer, the hole diameter of the needle holes is 1.9mm, the depth of the needle punching is three quarters of the thickness of the fiber cotton layer, and the needle punching density is 1.3...

Embodiment 3

[0066] The film-coated 3D sound-absorbing body includes a sequentially compounded cover layer, a first polyester staple fiber web layer, and a fiber cotton layer; the fiber cotton layer includes the first polyester staple fiber and the second polyester staple fiber evenly distributed in the first polyester staple fiber Two polyester staple fibers; the quality of the first polyester staple fiber net layer is 4% of the fiber cotton layer quality; the melting point of the first polyester staple fibers is 198 ° C; the melting point of the second polyester staple fibers is 266 ° C .

[0067] The ratio of the second polyester staple fiber to the first polyester staple fiber in the fiber cotton layer is 1:2.2.

[0068] There are acupuncture holes evenly distributed on the surface of the fiber cotton layer, the diameter of the needle hole is 1.5mm, the depth of acupuncture is 4 / 5 of the thickness of the fiber cotton layer, and the needle punching density is 1.4 needles / cm 2 .

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com