Construction method of a unit-assembled skeleton partition system

A construction method and prefabricated technology, applied in the direction of wall, building material processing, building components, etc., can solve the problems of inability to meet the coordination and unity of the five elements, inability to meet the development of the times, serious cross-contamination, etc., to avoid quality defects and save money. The effect of labor cost and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

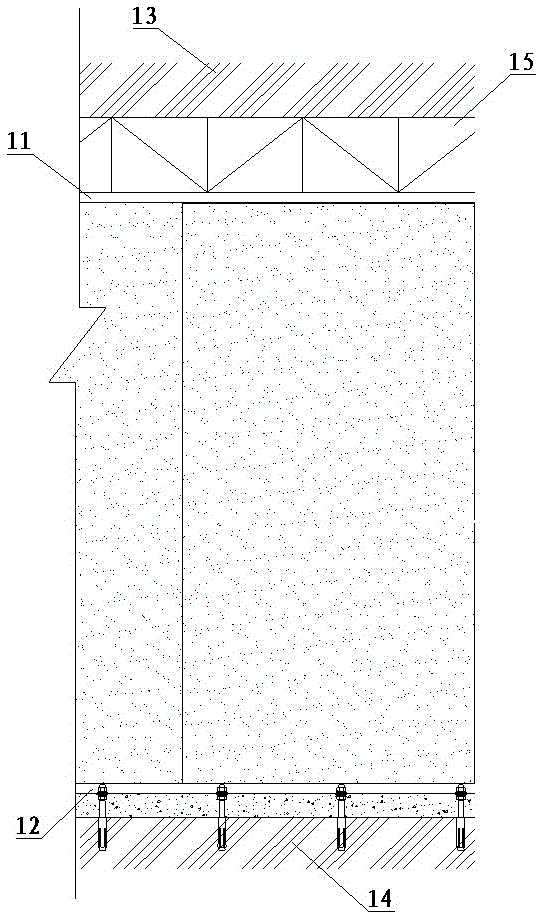

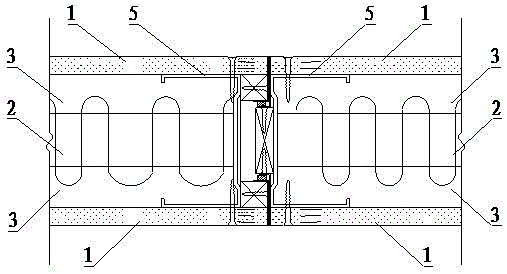

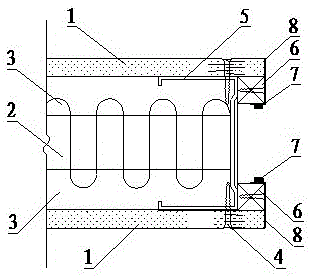

[0033] like Figure 1 to Figure 4 Shown is an embodiment of a unit-assembled skeleton partition wall system according to the present invention. The skeleton partition wall system includes a partition wall unit and an assembly structure. The partition wall unit includes a connecting structure and two partition wall half-units, each Partition wall half unit includes cover panel 1, screw 4, partition wall main keel 5, center keel 2, fireproof and soundproof cotton 3, cover panel 1 has two pieces, two cover panels 1 are arranged in parallel, there are multiple screws 4, and the partition wall The two ends of the main keel 5 of the wall are fixedly connected to the inner side walls of the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com