One-touch smart brake device of pumping unit

A technology of braking device and pumping unit, which is applied in the direction of braking actuator, mechanical equipment, gear shifting mechanism, etc., can solve the problems of complicated operation steps, inaccurate positioning and inability to control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific examples.

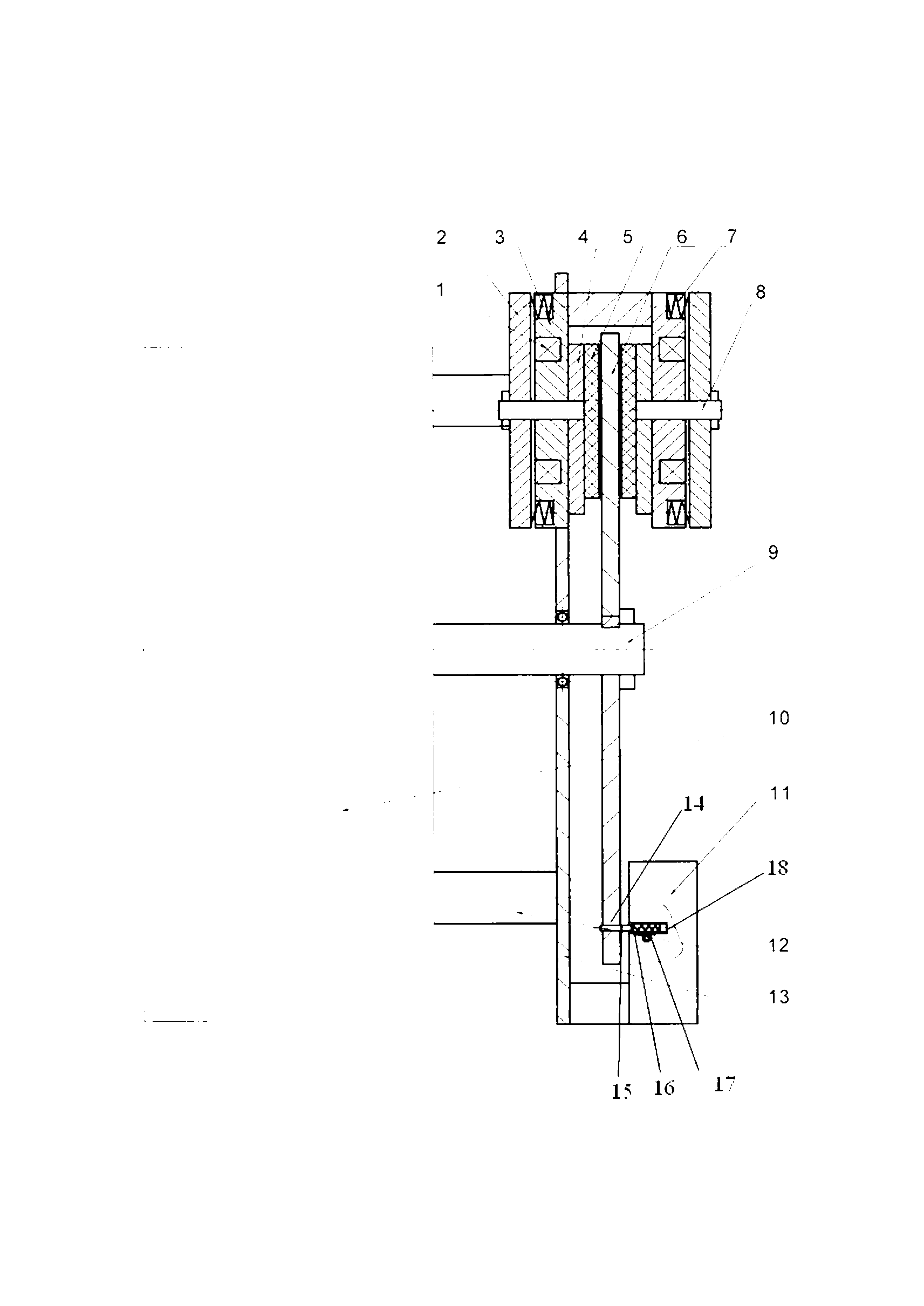

[0028] The one-button intelligent braking device of the pumping unit of the present invention includes a brake, a control cabinet and a sensor. Use the sensor to collect the signal, transmit it to the control cabinet, use the programmable logic controller (PLC) to control the brake through programming, realize the start and stop of the pumping unit and control the stop position of the pumping unit.

[0029] The brake includes a reducer 10, a brake actuator and a self-locking mechanism 11; the reducer 10 includes a reducer shaft 9, a brake disc 6, a connecting plate fixing column 12 and a connecting plate 13, and the connecting plate 13 passes through The connection plate fixing column 12 is fixed on the shell of the reducer 10, and the brake disc 6 is fixed on the front e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com