Proportional valve with improved sealing fit

A proportional valve and sealing element technology, applied in the field of proportional valves, can solve problems such as improving valve seat sealing, and achieve the effects of effective sealing, improved sealing, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

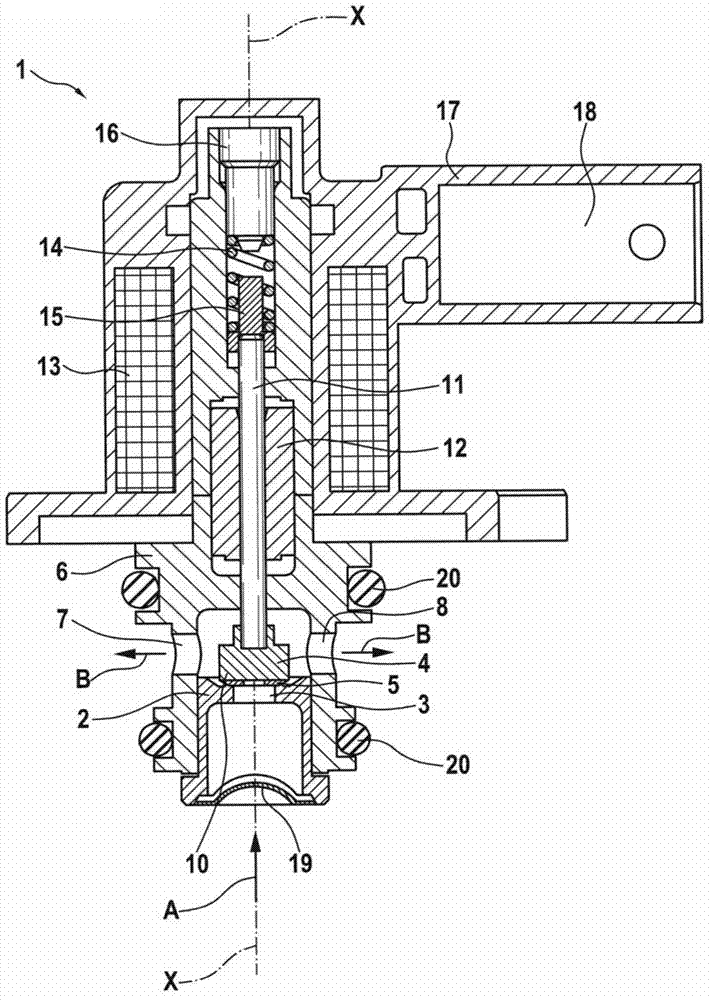

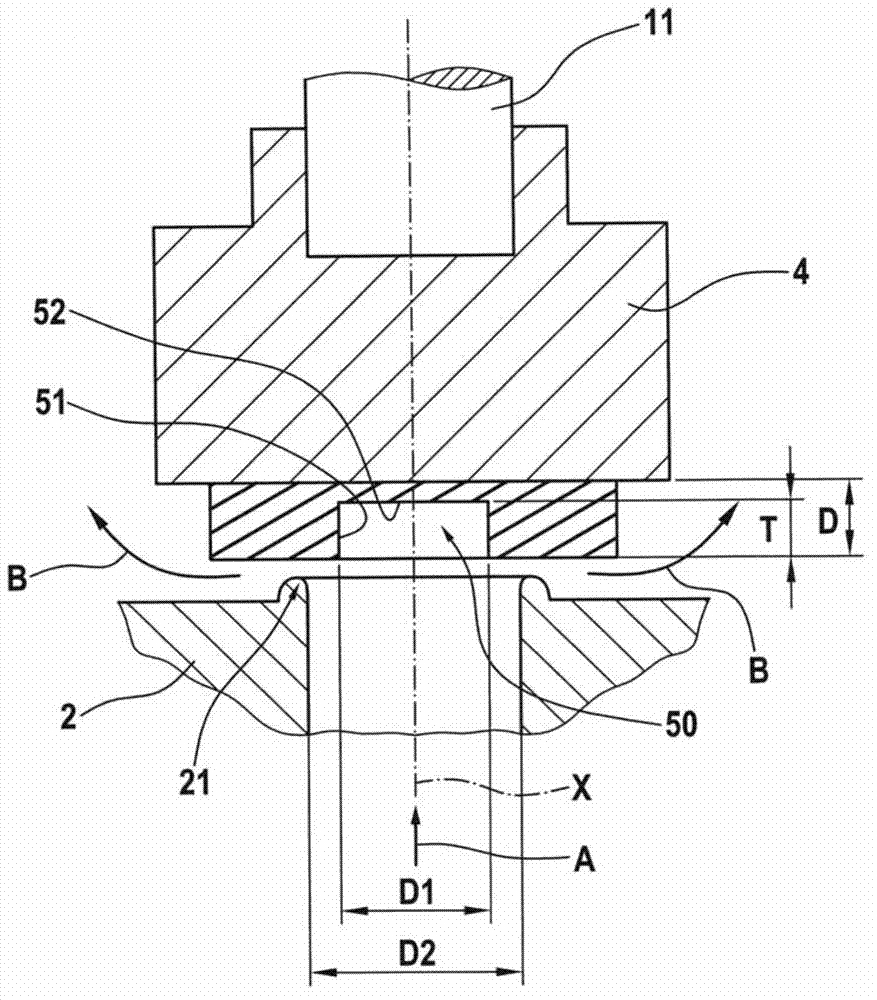

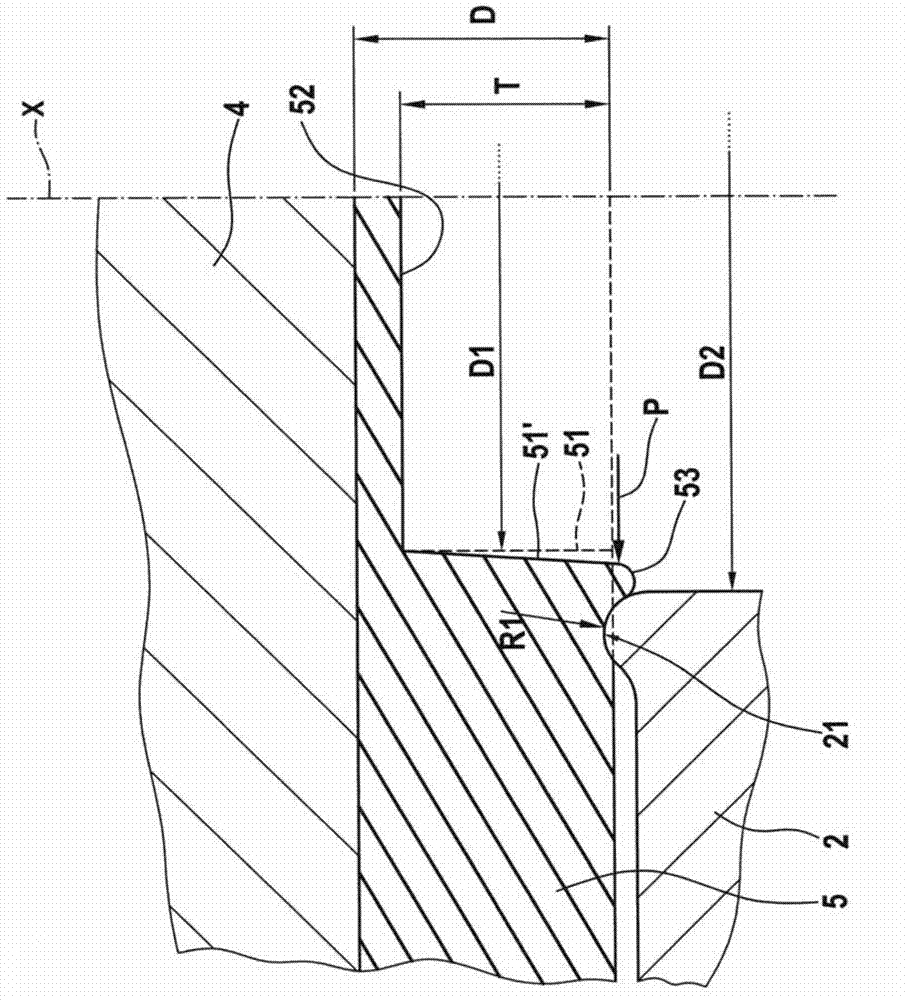

[0020] Refer below Figures 1 to 3 A proportional valve 1 for controlling a gaseous medium according to a first embodiment will be described in detail. The proportional valve 1 shown in these figures serves here to control gaseous hydrogen, which is supplied, for example, to a fuel cell in a motor vehicle.

[0021] Such as figure 1 As shown, the proportional valve 1 comprises a valve housing 6 with a magnetic armature 12 , a coil 13 and a rod 11 connected to the magnetic armature 12 . A closing spring 14 is connected to the lever 11 via a spring seat 15 . Reference numeral 16 designates an adjusting pin for adjusting the restoring force of the closing spring 14 . The coil 13 is fastened in a plastic overmolding 17 on the valve housing 6 . An electrical plug connector 18 is arranged laterally on the proportional valve 1 . A closing element 4 is arranged on the end of the rod 11 opposite the closing spring 14 . The closing element 4 closes a central perforation 3 formed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com