Fan speed-increasing gearbox test bed capable of achieving pose controlling and spindle loading

A speed-increasing gearbox and test bench technology, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problem of not being able to truly simulate other applied loads, and achieve good motion characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention provides a test bench for a speed-up gearbox of a fan that realizes pose control and main shaft loading. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

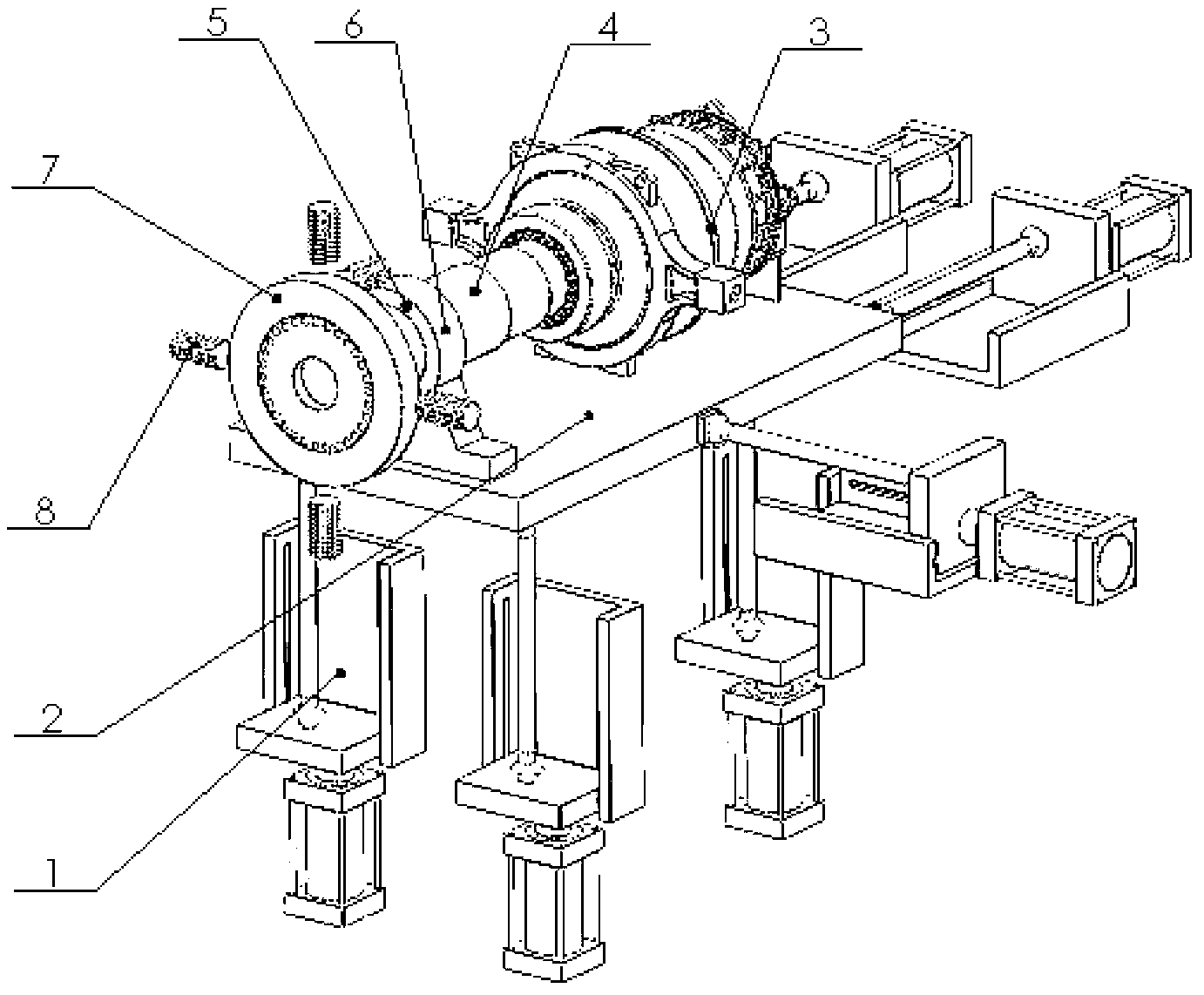

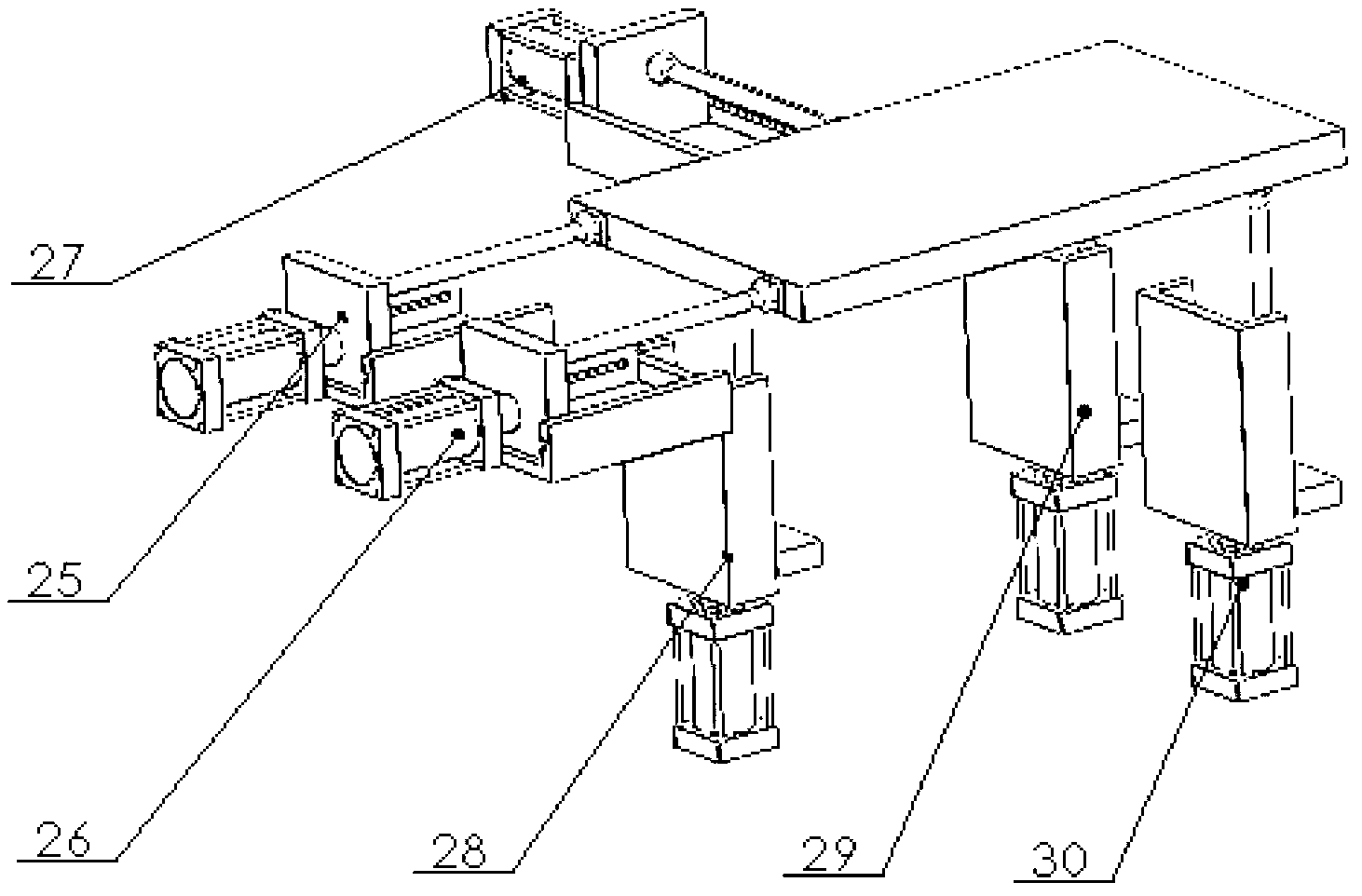

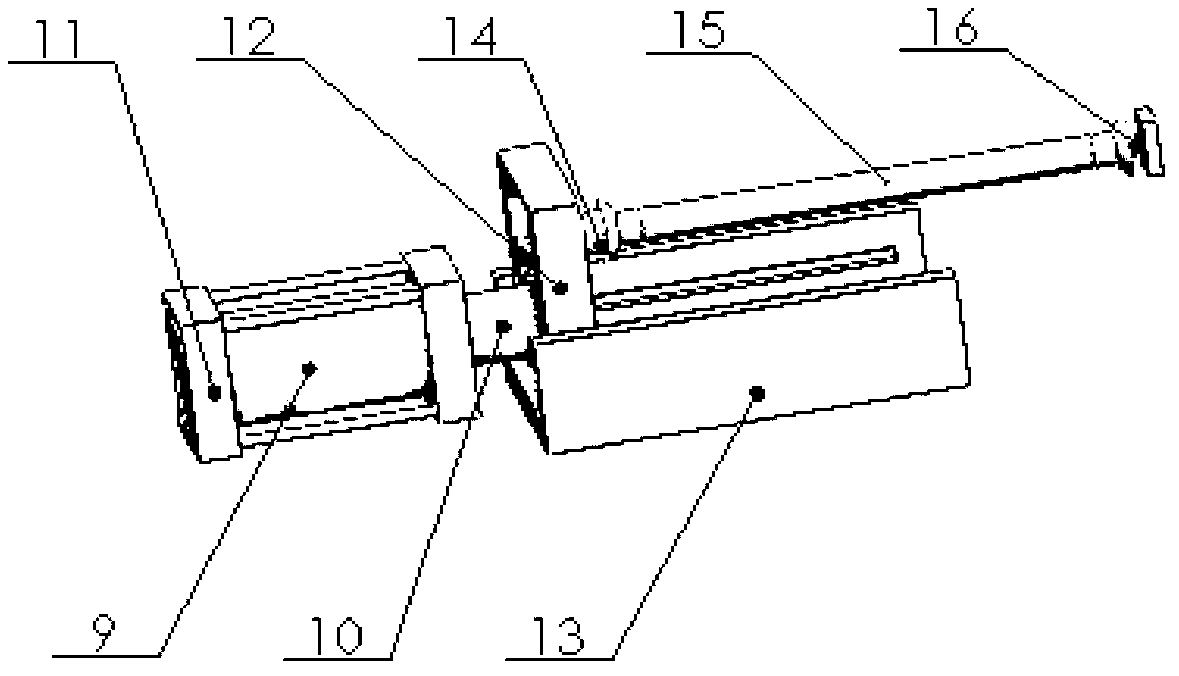

[0024] Such as figure 1 and figure 2 As shown, the fan speed-up gearbox test platform device of the present invention that realizes space six-degree-of-freedom pose control and non-contact spindle loading includes a pose loading drive device 1, a motion workbench 2 and a fan speed-up gearbox model 3; The six pose loading drive devices 1 are respectively installed on the side and bottom of the motion table 2, and the fan gearbox model 3 is installed on the top face of the motion table 2; the pose load drive device 1 adopts a 3-2-1 arrangement The method implements the control of position and attitude, and the specific position is: three posture loading drive devices 1 are fixedly connected to the bottom surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com