Novel linear electric loading system

A linear motor and linear technology, applied in the testing, measuring devices, instruments and other directions of machines/structural components, can solve the problems of large connection gap, poor dynamic performance, long loading reverse time, etc., to achieve high loading accuracy and improve dynamic performance. performance, eliminating the effect of long reverse times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

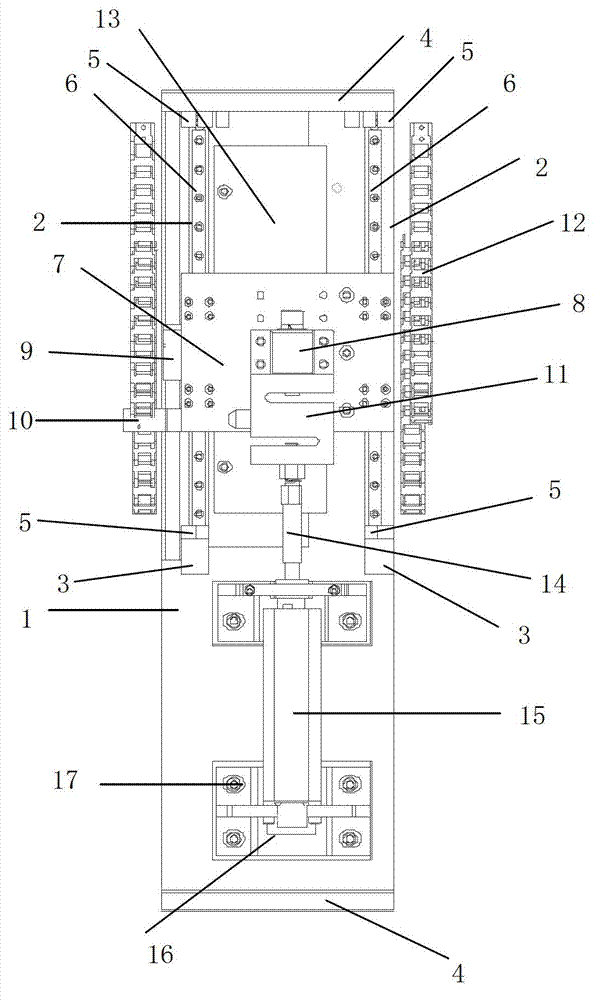

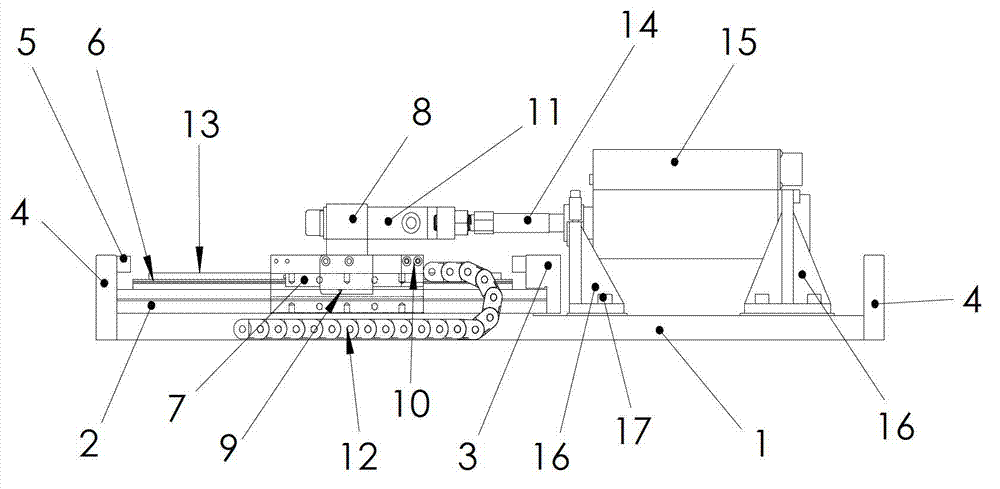

[0037] The present invention is a novel linear electric loading system, such as figure 1 , figure 2 As shown, it includes bottom plate 1, bottom plate boss 2, anti-collision block installation platform 3, anti-collision block 4, rubber block 5, guide rail 6, sliding platform 7, connecting block 8, magnetic scale 9, drag chain installation angle iron 10 , force sensor 11, drag chain 12, linear motor 13, threaded connecting rod 14, linear steering gear 15, support plate 16, fixing screw 17.

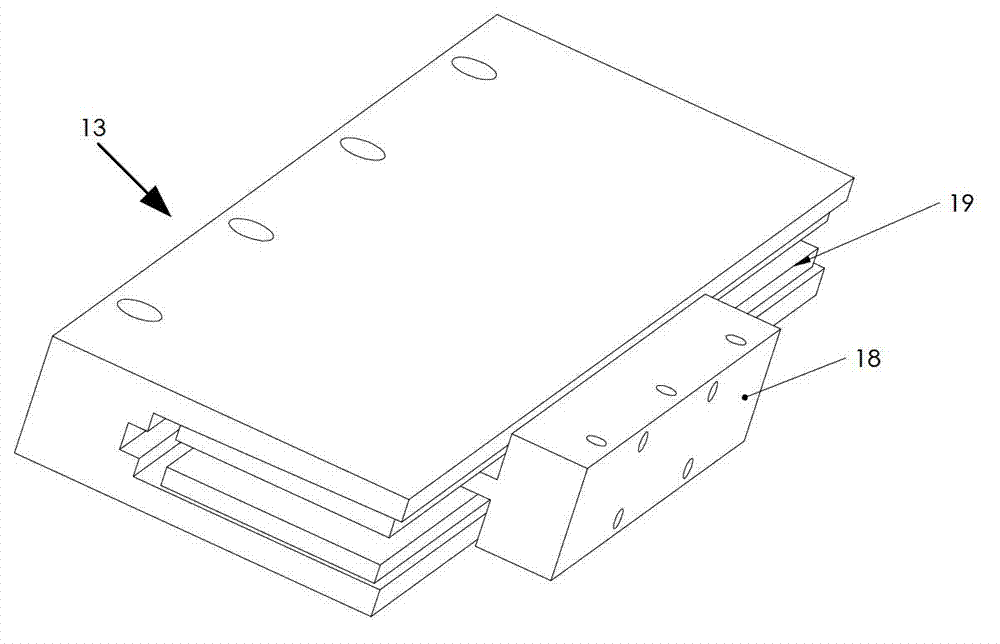

[0038] Linear motor 13 such as image 3 As shown, a motor coil 18 and a permanent magnet 19 are included.

[0039] The bottom plate 1 is rectangular, and anti-collision blocks 4 are respectively installed on the two wide sides of the rectangle, and the anti-collision block 4 and the bottom plate 1 are fixed by hexagon socket head screws.

[0040] An anti-colli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com