Single-surface multi-point non-contact pattern test method

A non-contact, test method technology, applied in measurement devices, material analysis by optical means, instruments, etc., can solve the problems of dense probes, long debugging time, complicated OGS graphics, etc. The effect of high penetration difficulty and shortened programming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

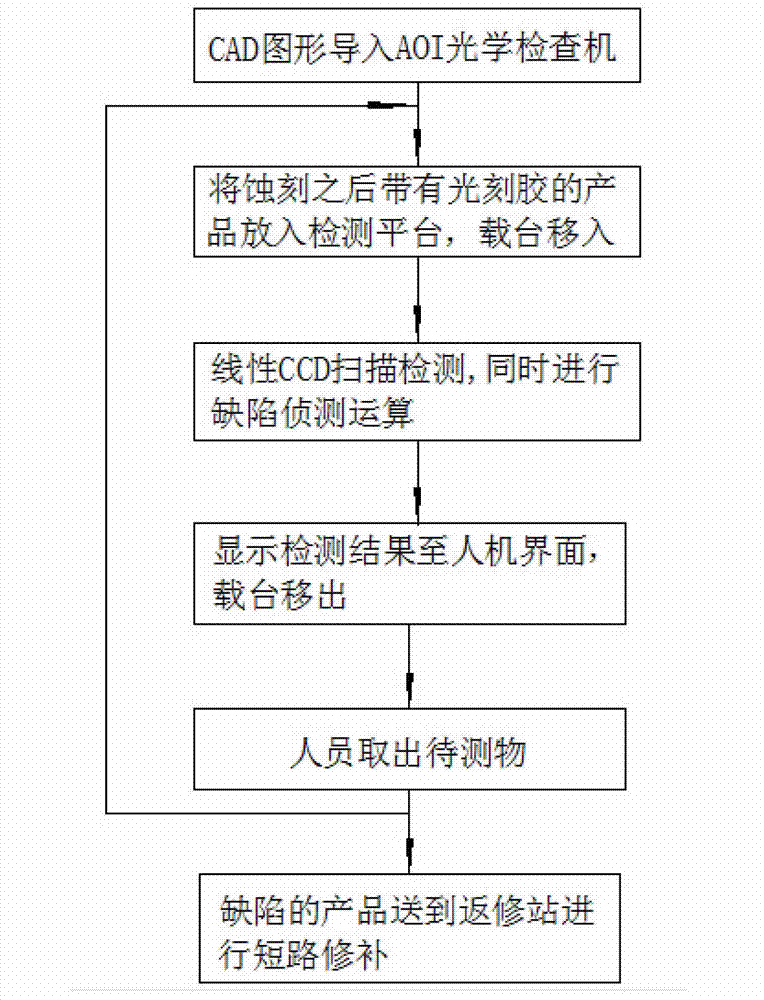

[0019] Such as figure 1 , 2 Shown, a kind of single-sided multi-point non-contact pattern test method, its main test process includes the following steps:

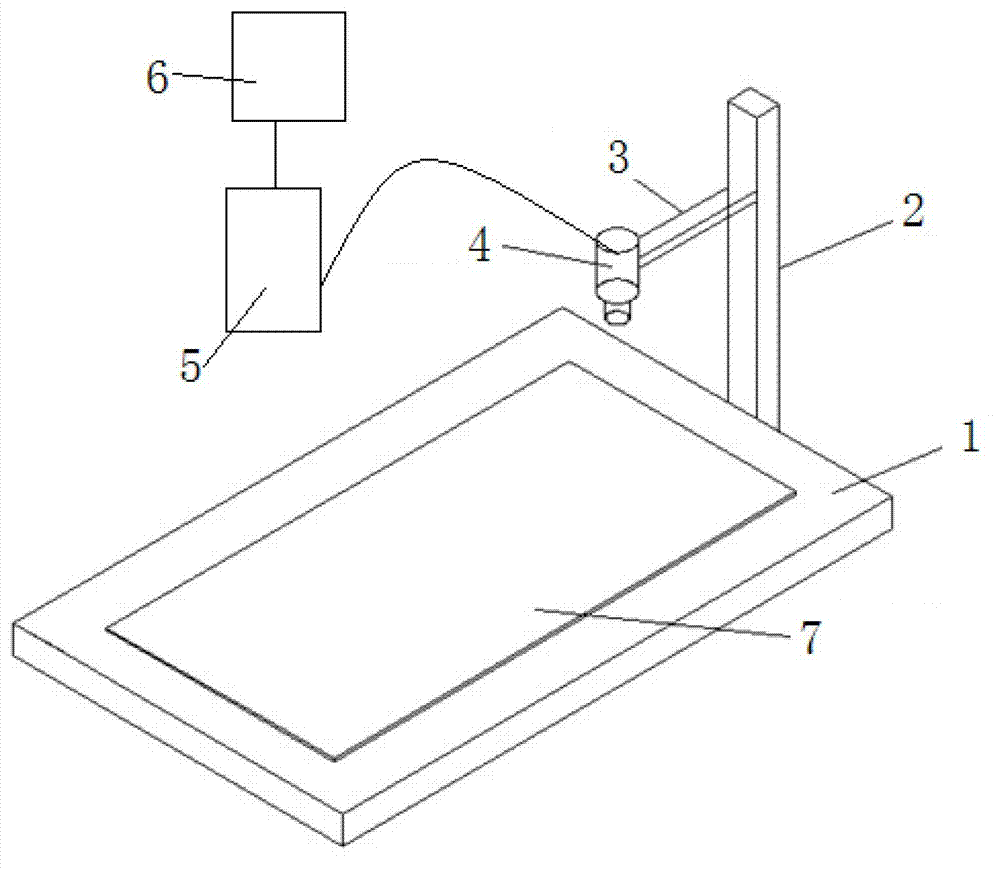

[0020] (1) Choose an AOI automatic optical inspection machine. The AOI automatic optical inspection machine includes a detection platform 1. A support rod 2 is fixed in the middle of one end of the detection platform 1. A beam 3 is fixed on the support rod 2. A facing beam 3 is fixed on the beam 3. The CCD camera 4 of the detection platform 1, the CCD camera 4 is connected to the computer 5, and the computer 5 is externally connected to the man-machine interface 6;

[0021] (2) Import the CAD graphics of single-sided multi-point graphics into the AOI automatic optical inspection machine, and call up the required inspection program through the learning wizard;

[0022] (3) Put the graphic product with photoresist after etching into the detection platform 1 of the AOI automatic optical inspection machine, and manually move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com