PLC controller and winding machine with same

A controller and winding machine technology, applied in program control, computer control, general control system, etc., can solve problems such as lack of implementation methods, and achieve the effects of stable winding process, extended service life and good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

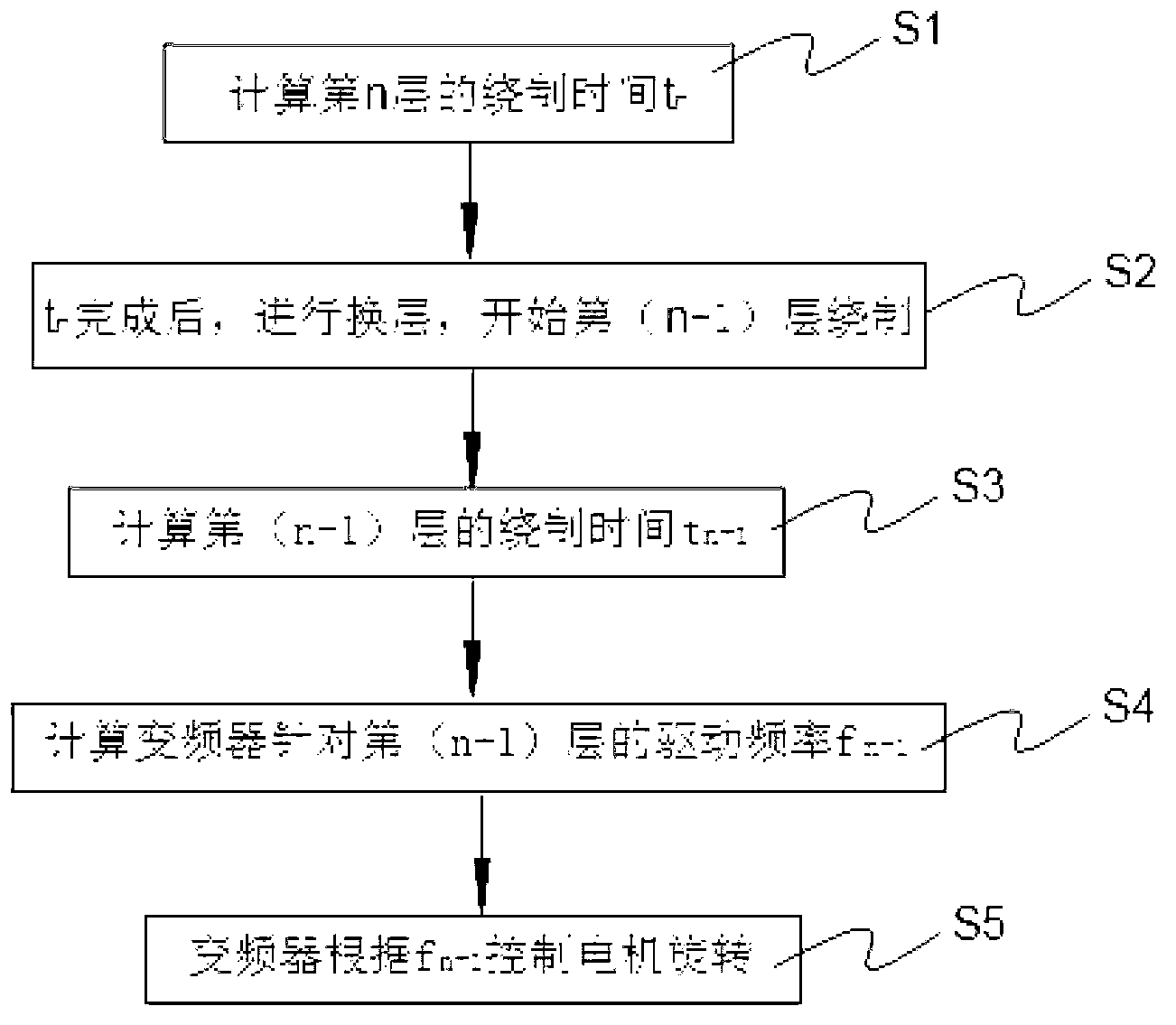

[0019] see figure 1 , figure 1 Shown is the flow chart of the method for the PLC controller 1 of the present invention to control the line speed. The PLC controller 1 includes:

[0020] Execute step S1: calculate the winding time t of the nth layer n , to complete the precise time predictive control of the nth layer; wherein, the winding time t n According to the number of coils M of the nth layer n and the radius R of the nth layer n Calculate the bus length L of the nth layer n , followed by the bus length L of the nth layer n Divided by the constant linear velocity v. Said n is any natural number value.

[0021] Execute step S2: when the winding time t of the nth layer n After the operation is completed, the layer is changed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com