Liquid target system

A liquid and neutron technology, applied in the field of liquid target system, can solve the problem of low neutron output rate, and achieve the effect of not easy to break down, simple structure and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

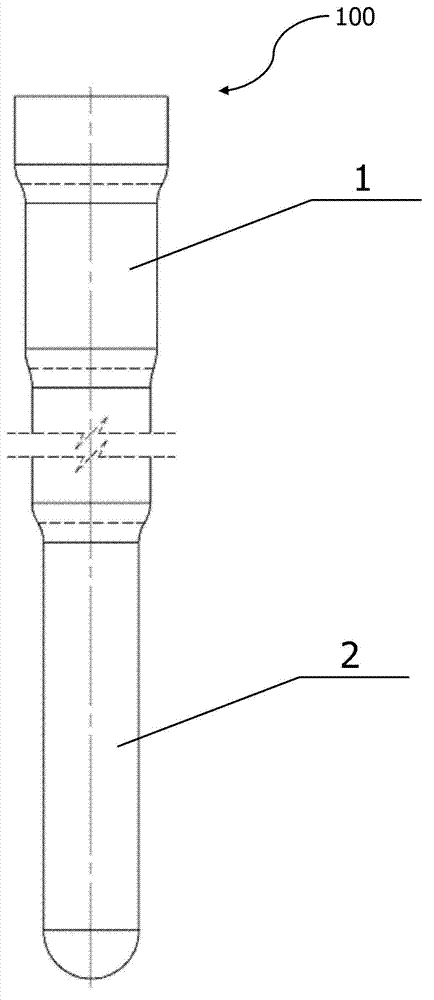

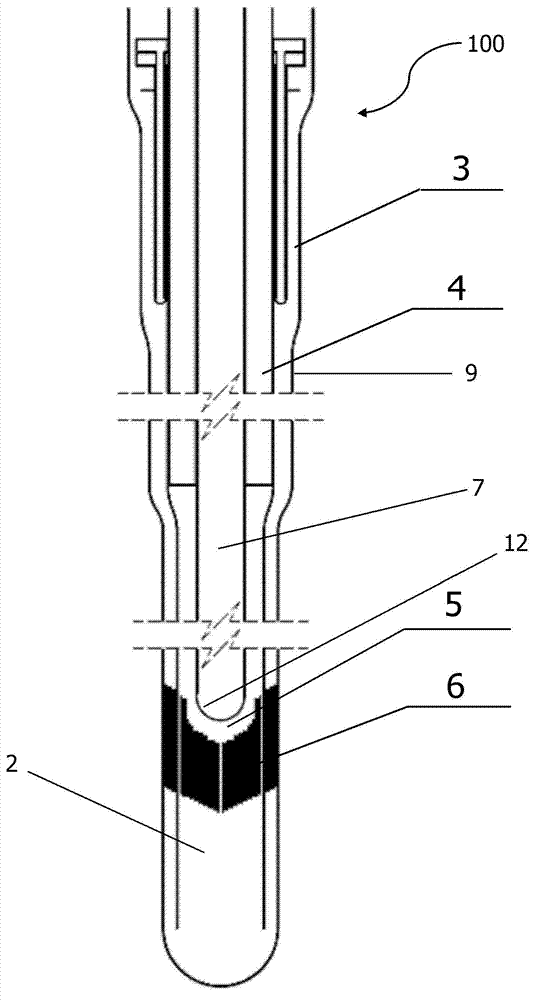

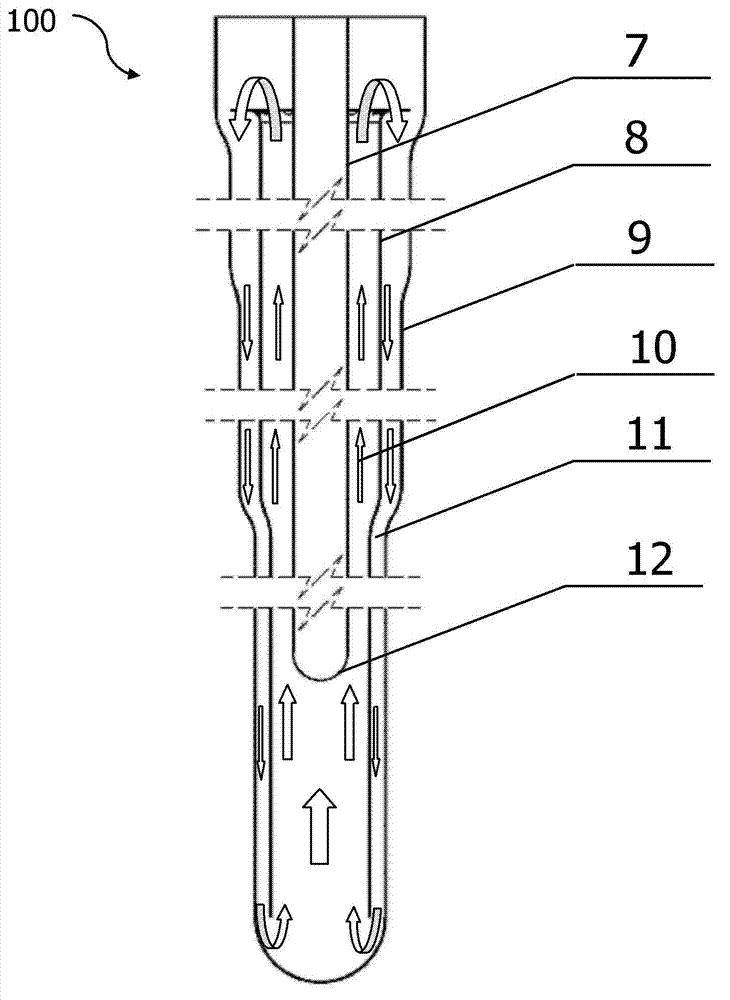

[0026] Figure 1 to Figure 3 A liquid target system 100 according to an exemplary embodiment of the present invention is shown. The overall structure of the liquid target system 100 may be an axisymmetric structure, and the liquid target system 100 may be installed in an ADS system or a neutron source system. The liquid target system 100 can be used as a neutron driving source in an accelerator-driven subcritical system (ADS), and can also be used as a neutron source in a spallation neutron source system, and can generate high-flux neutrons.

[0027] Such as figure 1 , 2 As shown, a liquid target system 100 according to an exemplary embodiment of the present invention includes a beam action area 5, and a neutron generating device 6 disposed in the beam action area 5, the neutron generating device 6 may be made of fissile material . Therefor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com