Display device and manufacturing method thereof

A technology of a display device and a manufacturing method, which is applied to electrical components, electrical solid-state devices, circuits, etc., can solve the problems of reducing the lifespan of organic light-emitting diodes, slowing down the manufacturing process speed of organic light-emitting diodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Various embodiments are presented below to describe in detail. The adhesive material is used to fill the space between the OLED panel and the frame, so that the display device can achieve high water resistance, high oxygen resistance, and the advantages of fast manufacturing process. However, the embodiments are only used for illustration and shall not limit the scope of protection of the present invention. In addition, some elements are omitted from the drawings in the embodiments to clearly show the technical characteristics of the present invention.

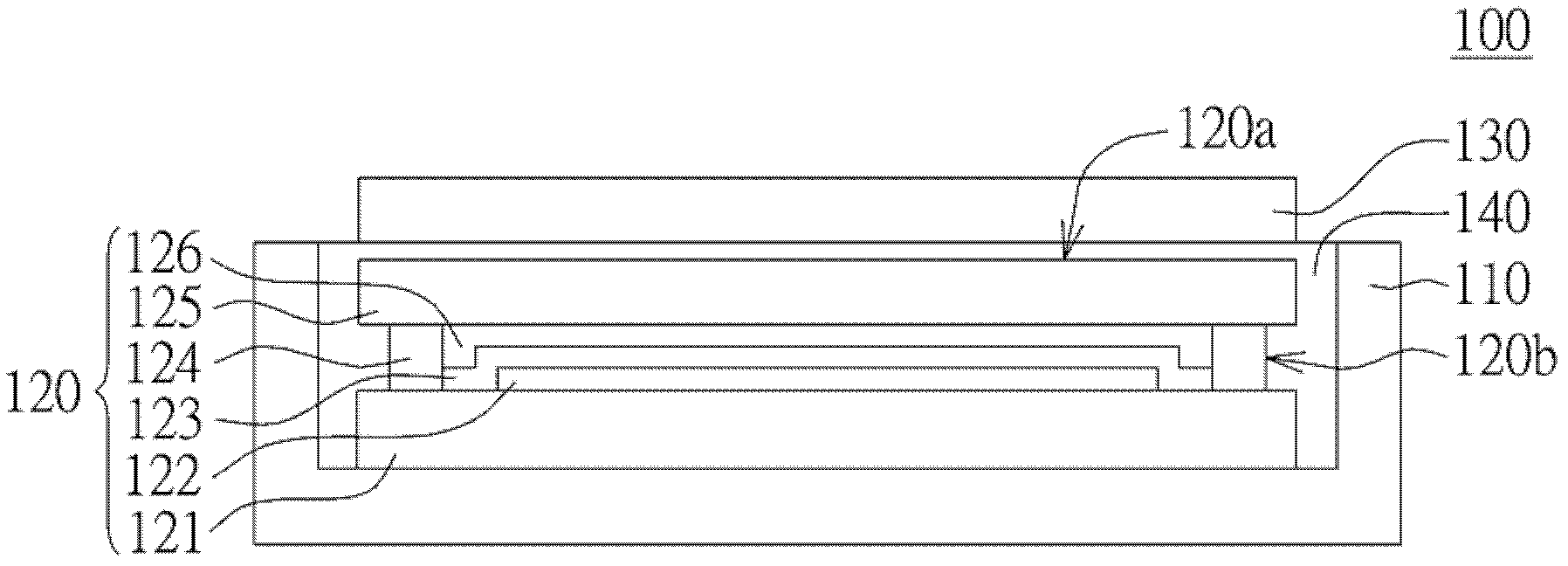

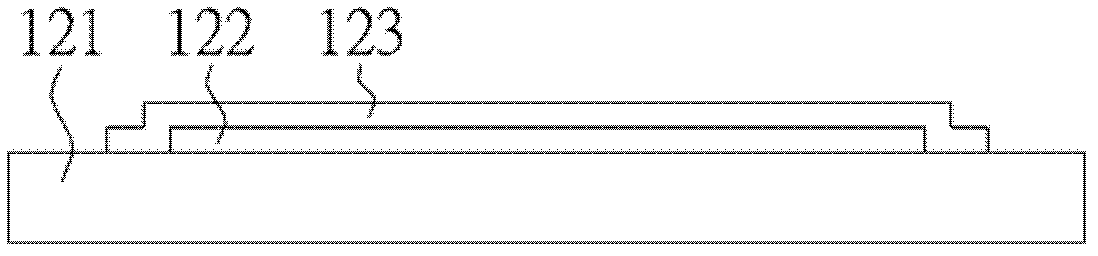

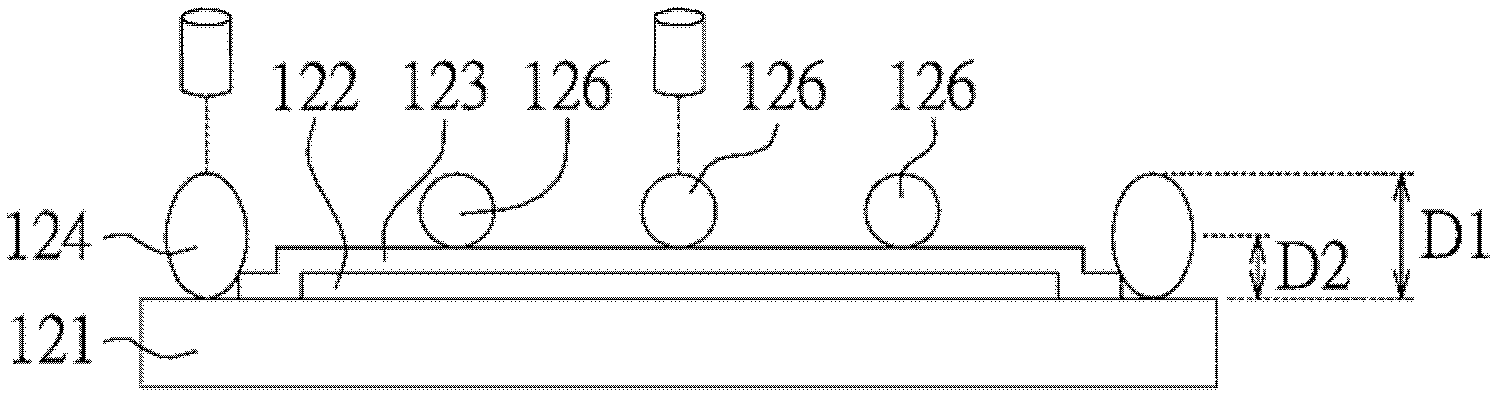

[0028] Please refer to figure 1 , which shows a schematic diagram of the display device 100 . The display device 100 includes a frame 110 , an OLED panel 120 , a light-transmitting element 130 and an adhesive material 140 . The frame 110 is used to carry and protect internal components of the display device 100 , such as an iron frame. The OLED panel 120 is, for example, active or passive. The OLED panel 120 is disp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Penetration rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com