System and method for electrified railway overhead line online ice resistance

A technology for electrified railways and anti-icing systems, applied in the installation of flexible AC power transmission systems, electrical components, cables, etc., can solve problems such as affecting the normal operation of trains, soil environmental pollution, and no application cases, and achieves a simple determination method. Anti-icing function, easy to implement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

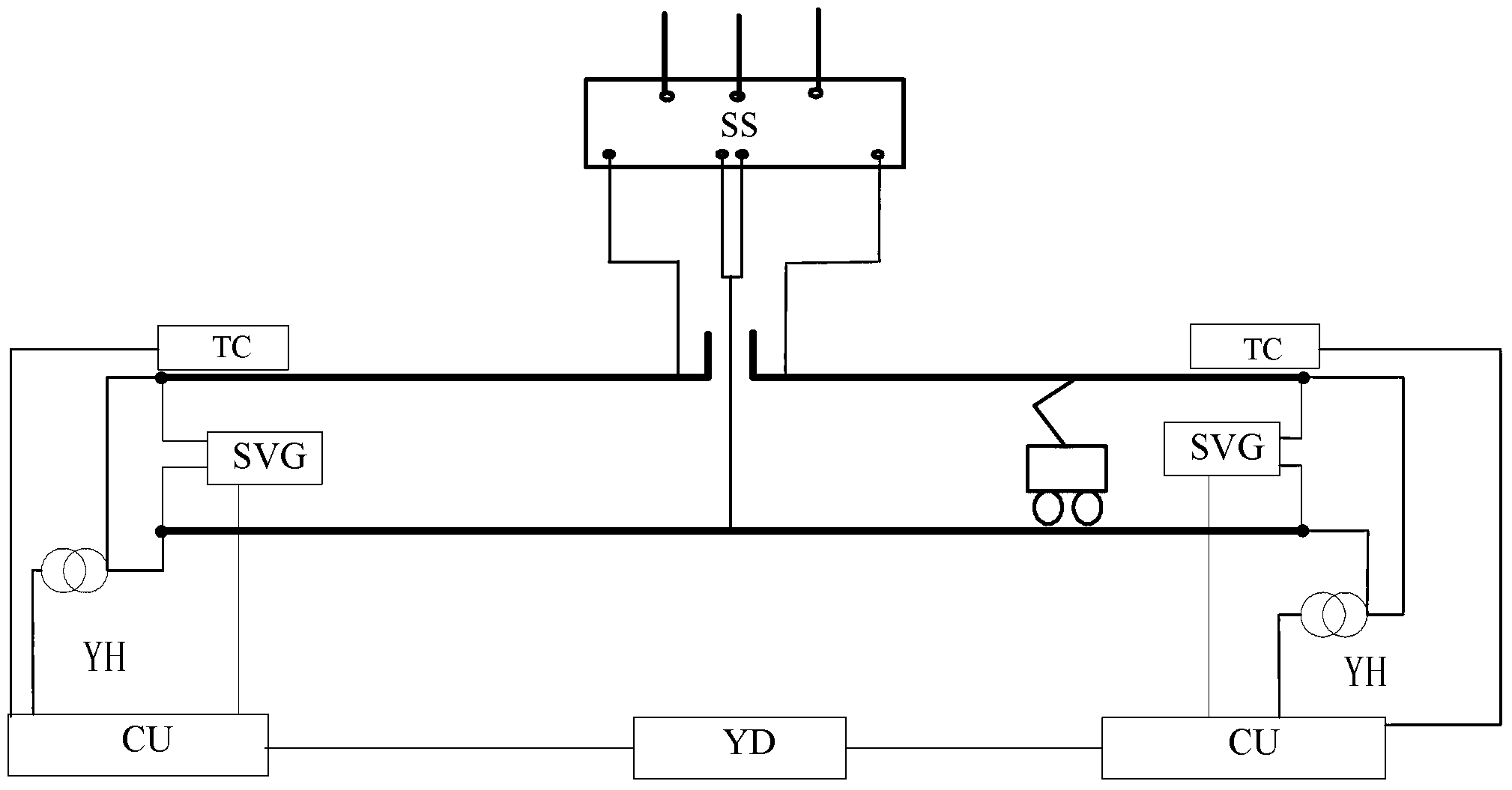

[0024] figure 1 It is shown that a specific implementation of the present invention is an on-line anti-icing system for an electrified railway catenary, which consists of a static var generator SVG and a voltage transformer at the end of the power supply arm of the electrified railway traction substation SS YH, contact wire temperature sensor TC and control unit CU; the control terminal of the static var generator SVG, the output terminal of the voltage transformer YH and the output terminal of the contact wire temperature sensor TC are connected to the control unit CU; at the same time the remote control device YD It is also connected to the control unit CU.

[0025] The method of using the catenary online anti-icing system for electrified railways of this example to perform catenary online anti-icing is as follows:

[0026] A. When the remote control device YD does not issue an anti-icing command and the temperature value output by the contact wire temperature sensor TC is highe...

Embodiment 2

[0031] This example is the situation where two sets of static var generators are installed in the SS power supply arm of the traction substation when the weather conditions are bad or the power supply arm is long, and the anti-icing current (capacity) of a set of static reactive power generators cannot meet the needs of anti-icing. . That is, the static reactive power generator SVG at the end of the SS power supply arm of the traction substation is limited by the lowest grid voltage at the end of the power supply arm where it is installed, and the anti-icing working current generated is less than the calculated current required for the catenary anti-icing; therefore, To meet the anti-icing requirements, in this example, on the basis of Example 1, a set of mid-section static reactive power generators, mid-section voltage transformers, mid-section contact wire temperature sensors and mid-section control units are added to the middle section of the power supply arm. The control te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com