Fuel level sensor for marine fuel vapor separator external to unit

A steam separator, marine fuel technology, applied in the direction of adding non-fuel substances to fuel, valves for ventilation, liquid fuel feeders, etc., can solve problems such as failure, leakage of transmission seal connectors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

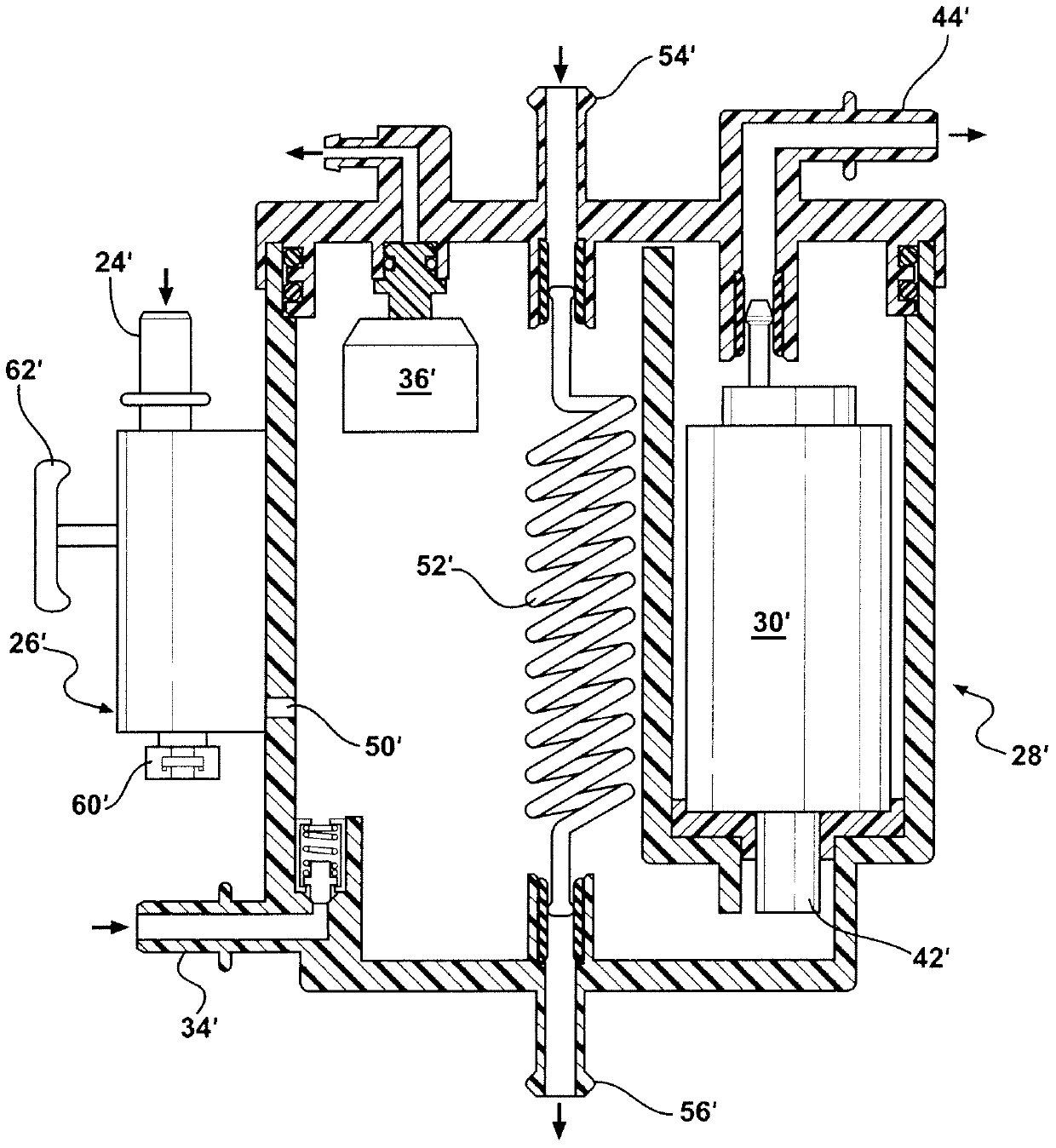

[0030] see Figure 4A with 4B, a fuel vapor separator constructed in accordance with one aspect of the present invention is shown generally at 128 . For the sake of convenience, features similar to or corresponding to those described above are denoted by numerical values that differ by 100 from the previously determined reference numerals. In this design, the buoy assembly 148 includes a puck-like buoy body 180 slidably carried on a short shaft 182 that extends downwardly from a cover 184 on the housing 146 . A positioning collet 186 is attached as a retainer to the distal end of the shaft 182 to retain the buoy 180 on the shaft 182 and within the vapor separator 128 . The buoy body 180 may be circular or any other suitable shape. The buoy body 180 has a lower density relative to the engine's preferred fuel, and therefore, the buoy body 180 responds to the level of fuel in the vapor separator unit 128 and is along the axis 182 at the upper constraint established by the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com