Heat exchanger

A technology for heat exchangers and refrigerators, applied in heat exchange equipment, heat exchanger shells, indirect heat exchangers, etc., can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

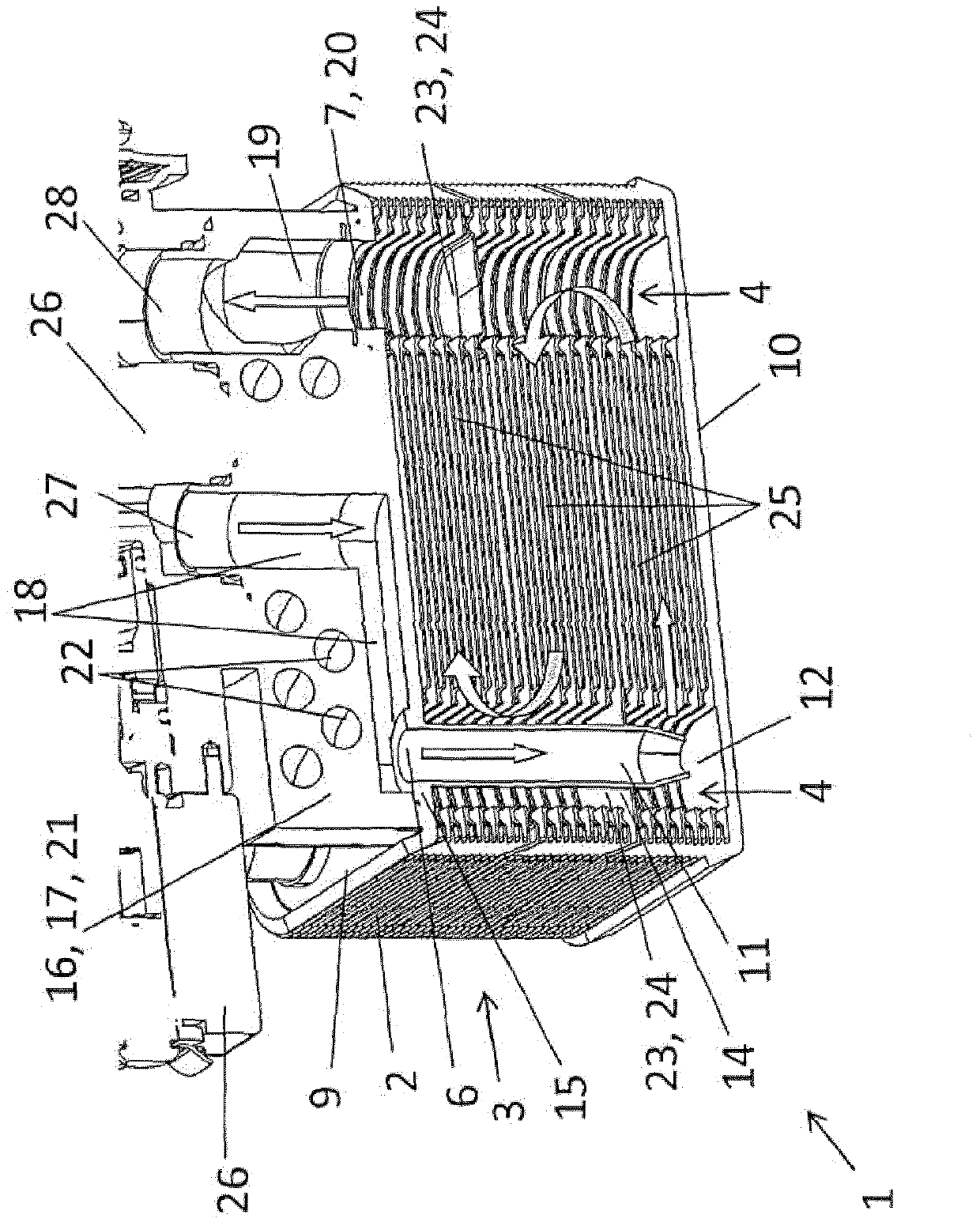

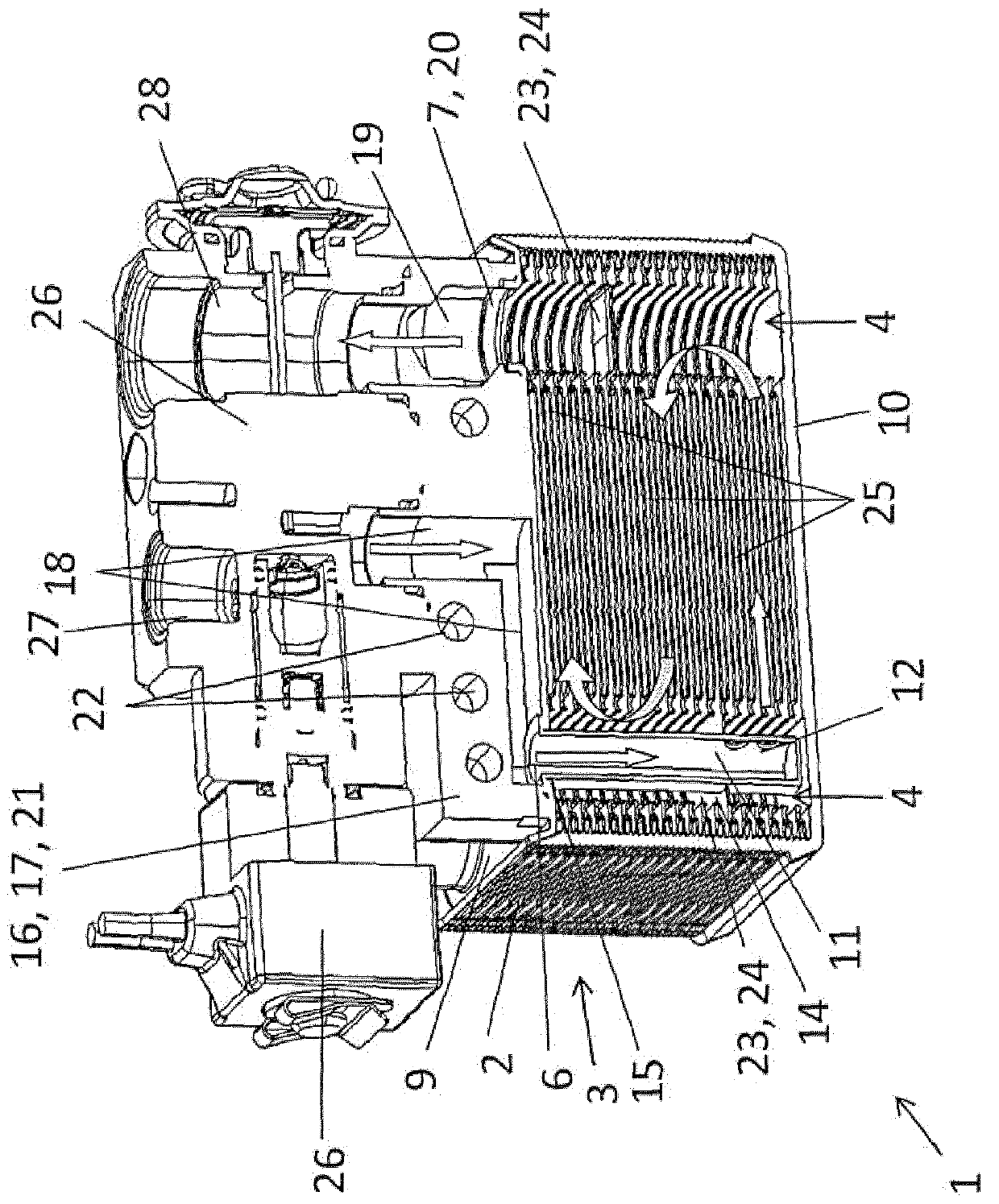

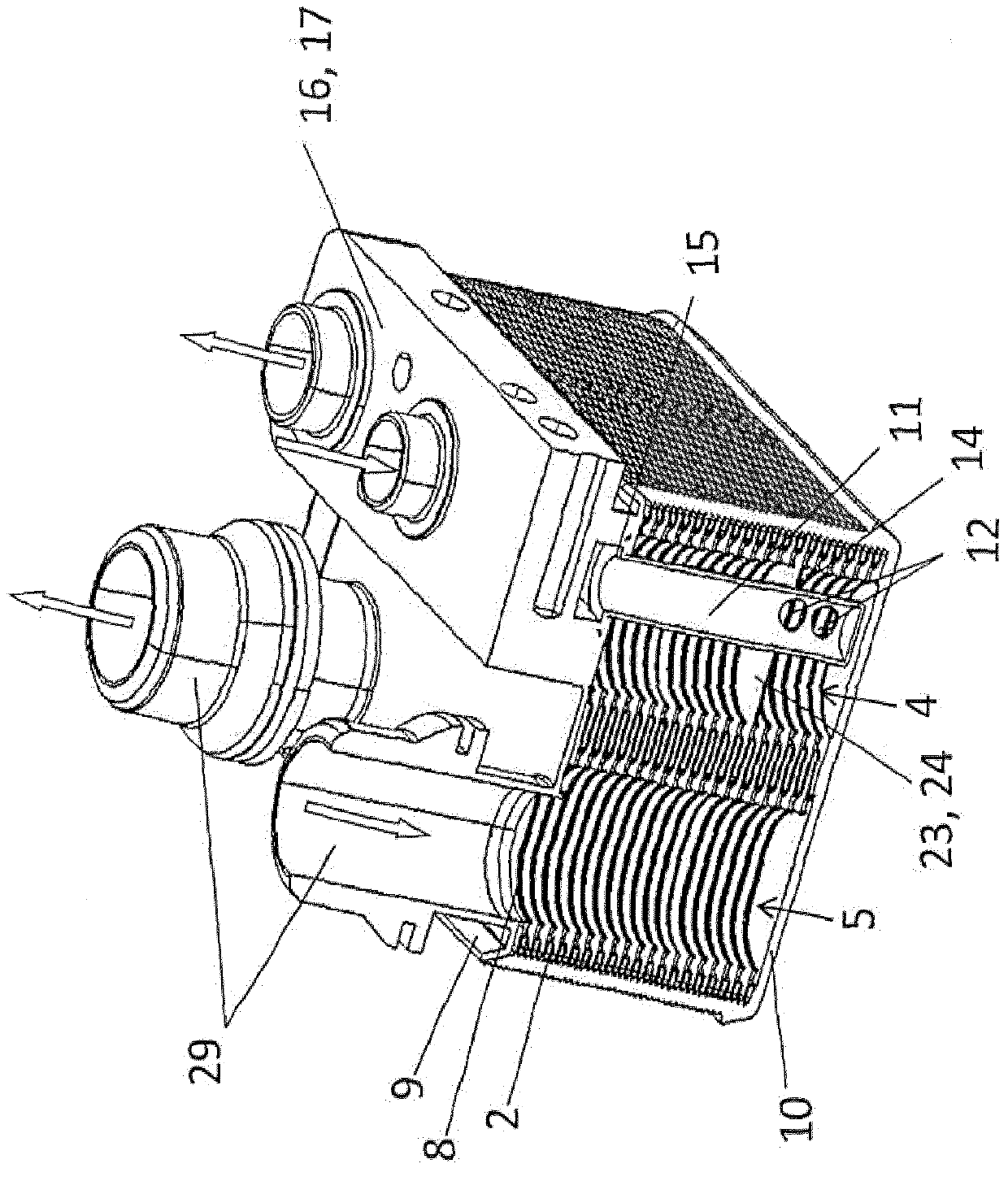

[0082] In the side view of FIG. 1 , the shown heat exchanger 1 or cooler 1 is installed in a not shown system for heating and / or cooling the battery of a vehicle (as a hybrid or electric vehicle). The heat exchanger 1 is designed here as a heat exchanger 1 in the form of a laminate. A plurality of stacked sheets 2 with first and second notches 4 , 5 or holes 4 , 5 are stacked vertically to form a stack 3 . Thus, a first fluid channel and a second fluid channel may be provided between the stacked sheets 2 for conveying fluid. Thus, heat can be transferred from the first fluid to the second fluid, or vice versa. The first opening 4 likewise forms a first fluid channel through which a first fluid flows into and out of the first fluid channel between the stacked lamellae 2 . This also applies analogously to the second fluid channel or second opening 5 . According to the illustration in FIG. 1 , the stack 3 of stacked sheets 2 is closed at the upper end by a cover 9 and the stac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com