Double-headed water boiling flow line device of cured food

A mature food and assembly line technology, applied in food science, slaughtering, mixed meat equipment, etc., can solve problems such as high energy consumption and heat loss, achieve good results, reduce water consumption, and improve taste and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

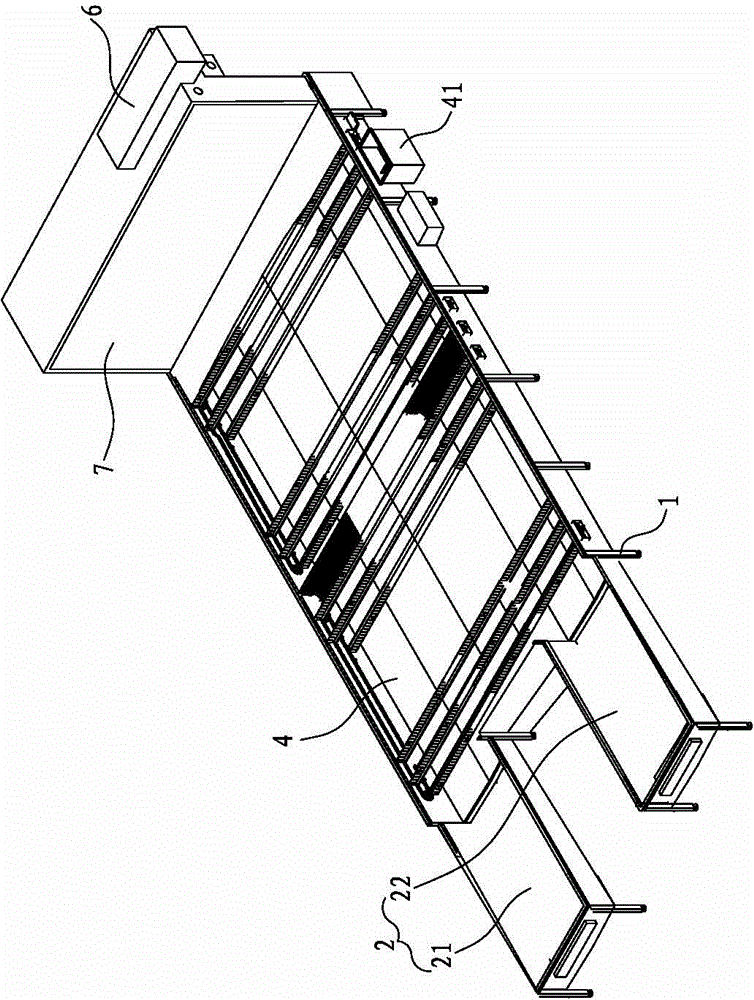

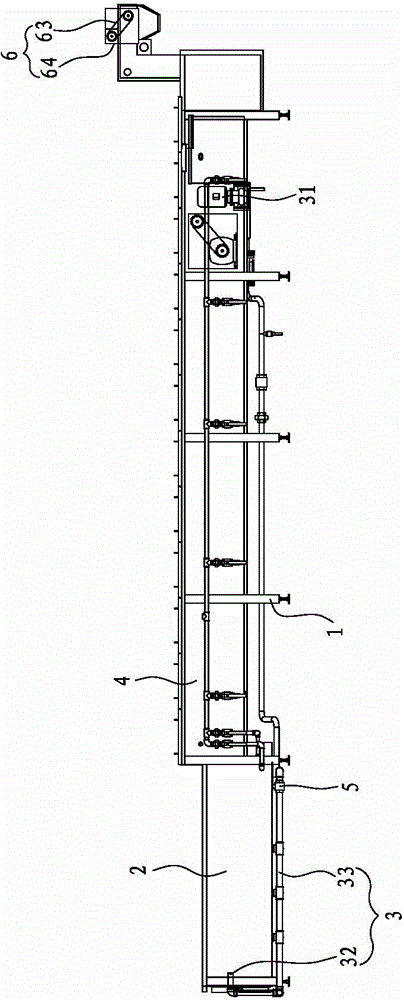

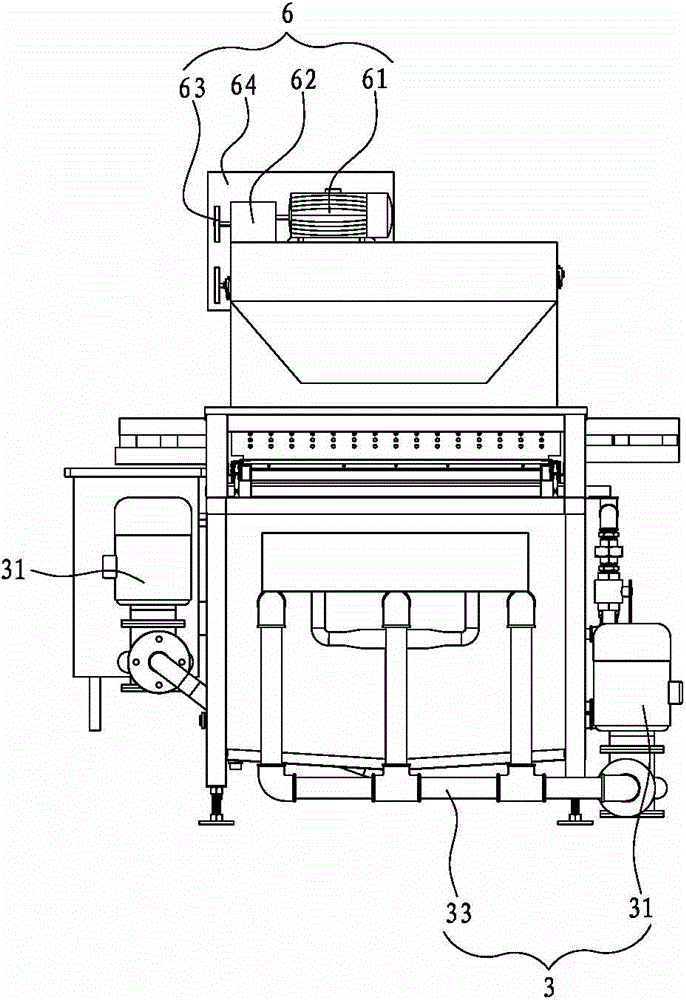

[0019] Such as figure 1 As shown, the present invention is a double-head boiling assembly line device for cooked food, which includes a frame 1, a feeding trough 2, two sets of boosting water circulation systems 3, a wide-body gel tank 4, a valve 5, a vertical lifting Mechanism 6, poaching tank 7.

[0020] The blanking chute 2 is composed of two rectangular forming troughs 21, 22, with a certain distance between the two forming troughs 21, 22 and they are parallel and flush. The front end is connected, and there is a certain height difference between the feeding opening section at the rear end of the forming tanks 21, 22 and the bottom of the wide-body gel tank 4, and the horizontal height of the bottom of the feeding opening section is lower than the bottom of the wide-body gel tank 4, so as to reduce the production process. Reduce water consumption, improve the resource utilization rate of the assembly line and the operability of water use.

[0021] The rear end of the wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com