Fin height adjusting mechanism of fin forming machine

A technology of adjusting mechanism and molding machine, which is applied in molding tools, heat exchange equipment, metal processing equipment, etc., can solve the problems of increasing the size of the molding machine and increasing the cost of the molding machine, and achieves high work efficiency, cost reduction, prevention of damage. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

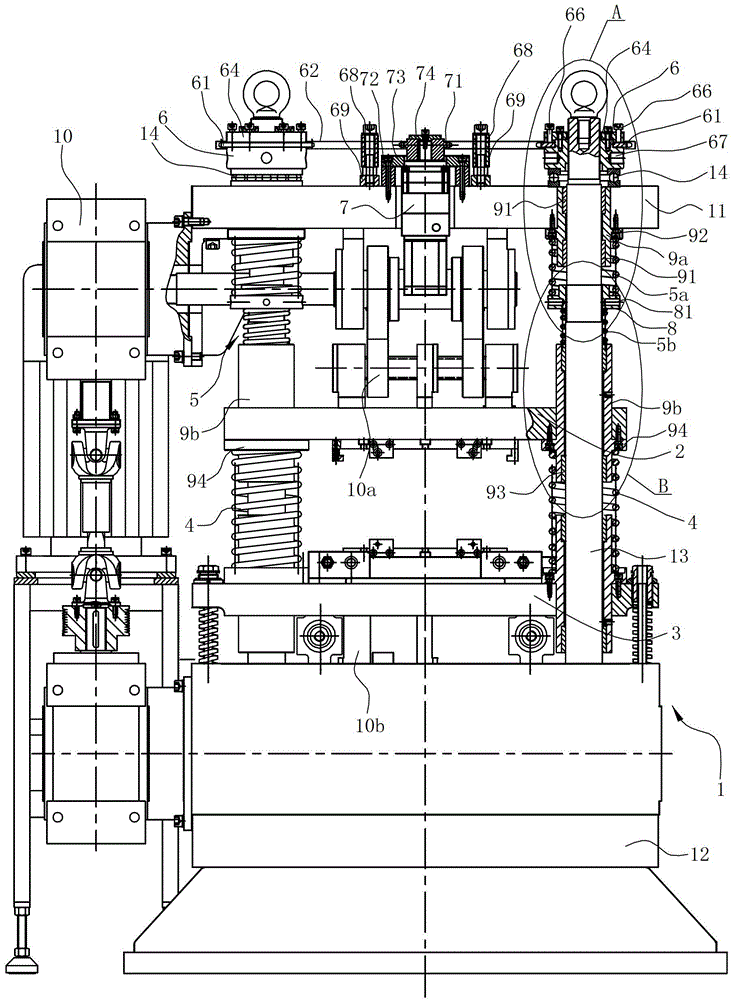

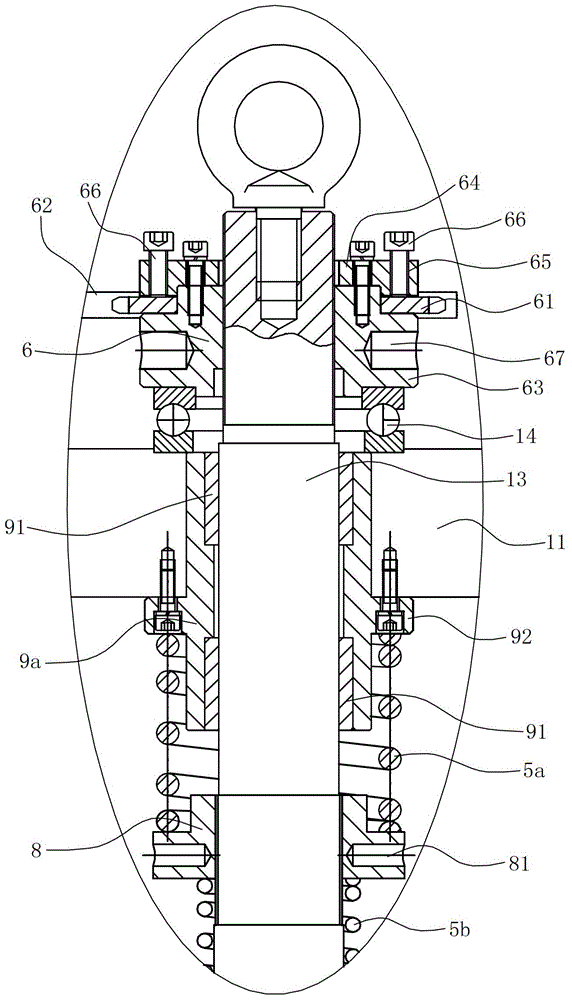

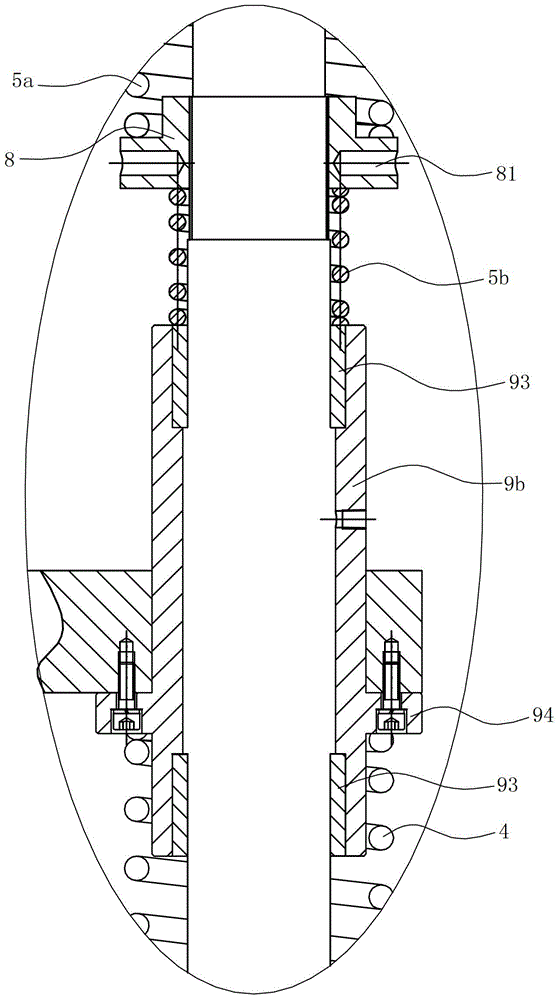

[0024] Such as Figure 1~4 Shown is a preferred embodiment of the present invention.

[0025] A fin height adjustment mechanism for a fin forming machine, comprising: a frame 1, which is composed of an upper board 11, a lower board 12 and a guide column 13 arranged between the upper board and the lower board, the upper board 11 It can move up and down relative to the guide post 13.

[0026] The main transmission structure 10 is located on one side of the frame.

[0027]The upper formwork 2 is arranged on the inner upper part of the frame 1 and can slide up and down along the guide pillars 13, and the upper formwork 2 is provided with an upper mold.

[0028] The lower formwork 3 is located at the lower part of the frame 1 and can slide up and down along the guide pillars 13, and the lower formwork 3 is provided with a lower mold.

[0029] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com