Plant fiber extruded product with internal vertical ribs, extruder and production method

A plant fiber and extruder technology, which is applied in the field of extruders to produce plant fiber extruded products with vertical ribs inside, which can solve the problems of difficulty in realizing continuous production, inability to set Z-axis vertical ribs, and strength problems And other problems, to achieve the effect of increasing farmers' income, good flatness, and good bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

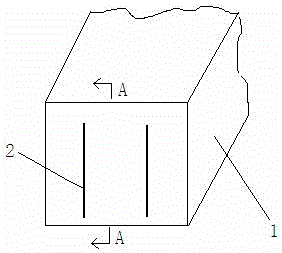

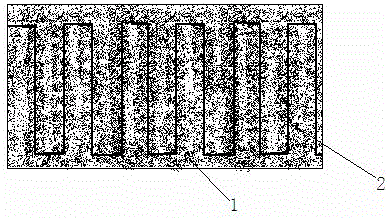

[0029] Such as figure 1 , figure 2 As shown, the present invention is an extruded product with vertical ribs 2 inside the body 1, the vertical ribs 2 are plastic ropes, and the body 1 is formed by bonding and extruding straw fibers and lignin-based glue.

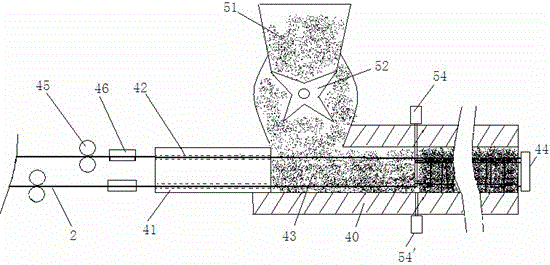

[0030] Such as image 3 shown, production figure 1 , figure 2 The extruder of the shown product comprises an extrusion head 41 and a mold cavity 43 surrounded by templates, the extrusion head 41 reciprocates in the stroke cavity of the mold cavity 43, and the rear side of the extrusion head 41 is provided with a friction clamp Holder 45 (friction wheel in this embodiment), the extrusion head 41 is provided with reinforcing ribs passing through the hole 42, the outlet end of the mold cavity 43 is provided with a fixing member 44, and the vertical ribs 2 pass through the friction clamping member 45, reinforcing Rib passes through hole 42, die cavity 43, is fixed on fixture 44, and the template 40 top of stroke chamber an...

Embodiment 2

[0036] Such as Figure 4 As shown, the present invention is an extruded product with vertical ribs 2, longitudinal ribs 3, and weft ribs 4 inside the body 1, the vertical ribs 2, weft ribs 4 are fiber ropes, the longitudinal ribs 3 are steel wires, and the body 1 It is bonded and extruded by straw fiber and starch glue.

[0037] Such as Figure 5 shown, production Figure 4The extruder of the shown product comprises an extrusion head 41 and a mold cavity 43 surrounded by templates, the extrusion head 41 reciprocates in the stroke cavity of the mold cavity 43, and the rear side of the extrusion head 41 is provided with a friction clamp Holder 45 (friction wheel in this embodiment), the extrusion head 41 is provided with reinforcing ribs passing through the hole 42, the outlet end of the mold cavity 43 is provided with a fixing piece 44, and the vertical ribs 2, longitudinal ribs 3 and weft ribs 4 are passed through in turn. Over-friction clamping part 45, reinforcing rib pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com