Automatic stuff bubble removing device for gassed building block production

An air-entrained block and automatic cleaning technology, applied in supply devices, ceramic molding machines, manufacturing tools, etc., can solve problems affecting product quality and appearance aesthetics, affecting building safety, etc., and achieve the effect of improving quality and appearance aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

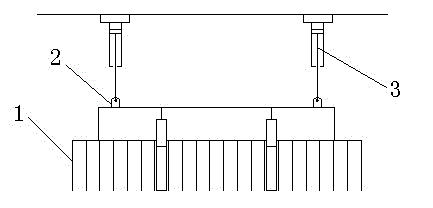

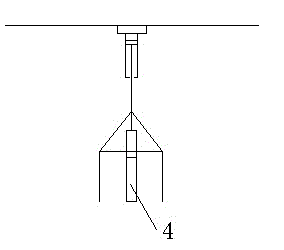

[0012] Combine below figure 1 and figure 2 , the present invention is further described:

[0013] Such as figure 1 and figure 2 As shown, the automatic cleaning device for slurry bubbles used in the production of aerated blocks includes a lifting platform and a bubble combing device connected to the lifting platform. The bubble combing device includes a bubble comb 1 and a vibrator 4 fixed on the bubble comb. The lifting platform includes two cylinders 3 and two photoelectric sensors. There is a solenoid valve on the cylinder 3. The solenoid valve is connected to the photoelectric sensor. The two ends of the bubble combing device are fixedly connected to the connecting plate 2. The piston rod of the cylinder 3 passes through the connecting plate 2. It is connected with the bubble combing device; the bubble comb 1 is provided with two rows of staggered evenly distributed comb teeth, and there are forty-nine comb teeth. Among the present invention, the vibrator 4 can be a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com