Air exhausting and bag placing synchronous on-line device of packing scale and implement method

A packaging scale and packaging bag technology, which is applied in the direction of packaging, transportation and packaging, and the type of packaging items, etc., can solve the problems of reduced volume utilization of packaging bags, moisture absorption and deterioration of materials in bags, and reduced net weight of materials, etc., to achieve increased volume Utilization rate, prevention of dust explosion, effect of reducing residual air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with the specific implementation of examples.

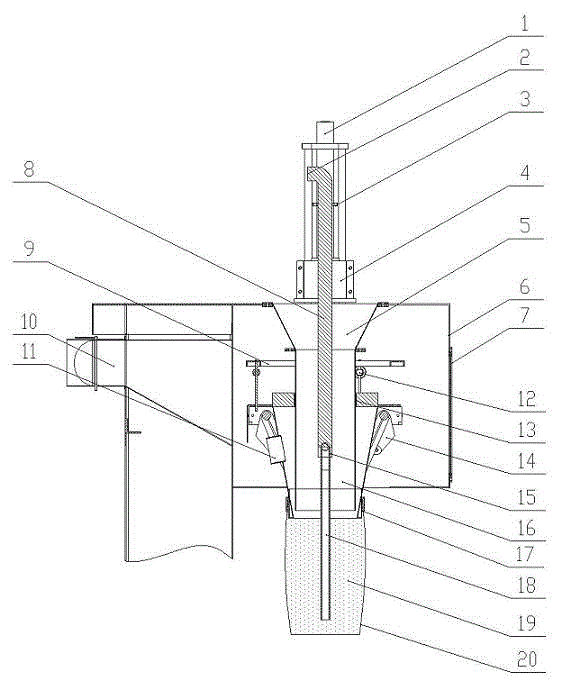

[0024] The online device for synchronously pumping air and releasing bags for a packaging scale includes a weighing body, a lifting mechanism 1 , an air suction pipe 8 , a bag clamp 14 , a connecting plate 9 , a sensor 12 and a dust cover 6 .

[0025] A transition bucket 5 and a feed pipe 16 arranged vertically are provided in the dust cover 6 . The shape of the transition bucket is rounded truncated. The upper end of the transition bucket 5 is fixed on the scale body, the lower end of the transition bucket 5 is connected to the feed pipe 16, and the lower end of the feed pipe 16 stretches out of the dust cover 6.

[0026] The air extraction pipe 8 is vertically arranged in the transition bucket 5 and is arranged on the scale body through the air extraction pipe flange 3 . The upper end of the exhaust pipe 8 stretches out of the transition bucket 5 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com