Packaging paper for forming straight packaging of cigarette packaging box, forming method and using method

A packaging box and wrapping paper technology, which is applied to the packaging of cigarettes, types of packaging items, packaging, etc., can solve the problems of complex structure of cigarette box blanks, complicated packaging process, and cigarette packs that cannot be closed again, so as to simplify the packaging process, The effect of reducing the structure of small folds and making it easy to take out and carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

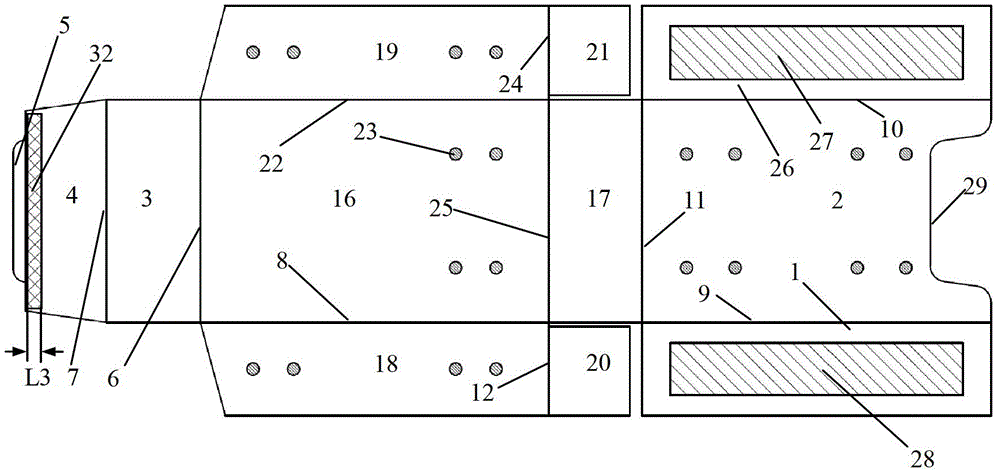

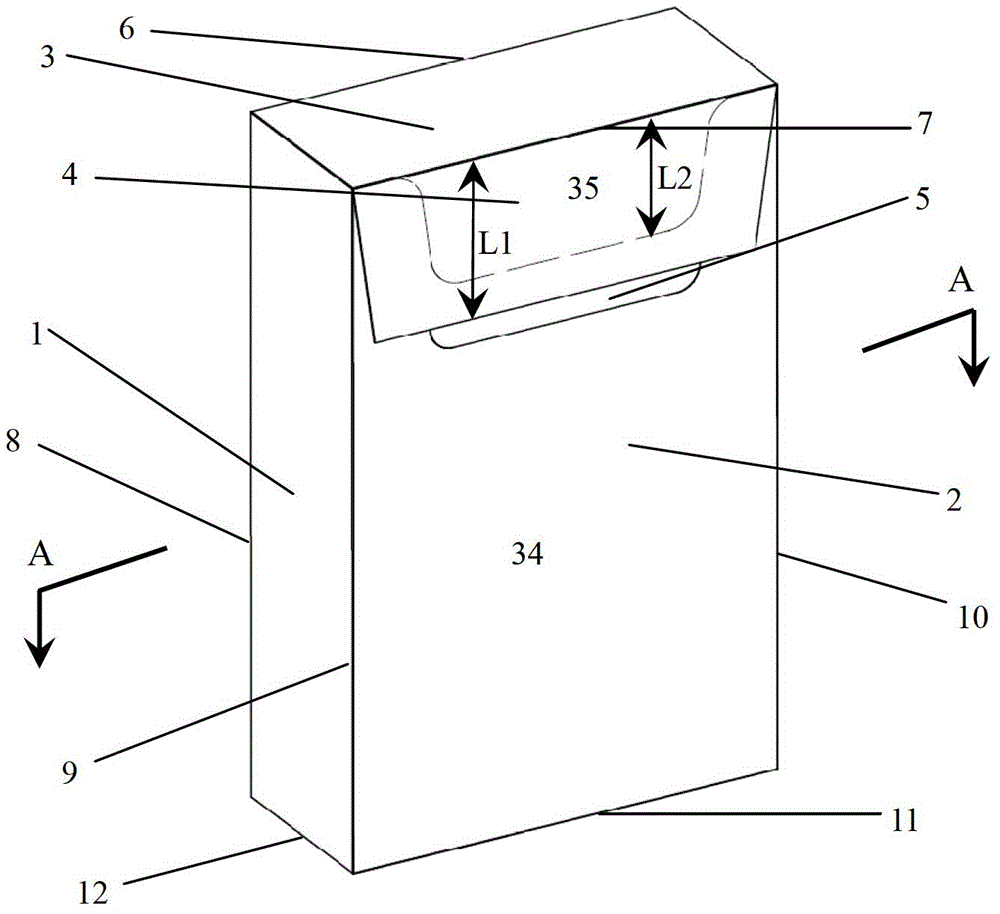

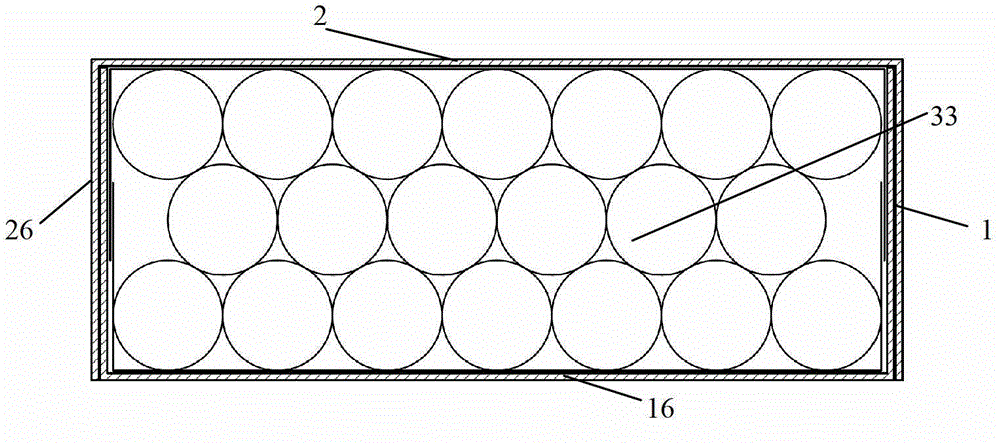

[0056] Such as Figure 1 to Figure 4 As shown, the present invention forms the wrapping paper of the cigarette packing box of vertical packing, is made of thin cardboard or similar packing material, after being folded, it is used as the outer packing box of cigarette; Body bottom wall 17, box body rear wall 16, cover sheet top wall 3, cover sheet front wall 4, cover sheet pull tab 5, the top of box body front wall 2 forms an inverted trapezoidal gap 29, both sides of box body front wall 2 Respectively connect box body left side wall 26, box body right side side wall 1, the both sides of box body rear wall 16 connect respectively box body left inner side wall 19, box body right inner side wall 18, the top of box body right inner side wall 18 connects box Body right inner knuckle 20, the top of box body left inner side wall 19 connects box body left inner knuckle 21; The bottom end of box body left inner side wall 19, box body right inner side wall 18 forms a slope;

[0057] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com